In the world of manufacturing, the demand for customized, special-shaped precision CNC components is on the rise. Industries such as aerospace, automotive, medical devices, and consumer electronics often require parts with unique geometries that standard machining processes cannot achieve. Customized machining of these special-shaped components involves advanced techniques, precise implementation, and thorough process exploration. This article will provide an in-depth introduction to the customized machining process of precision CNC parts with irregular shapes, and explore applicable machining processes to meet the professional knowledge needs of readers.

Application

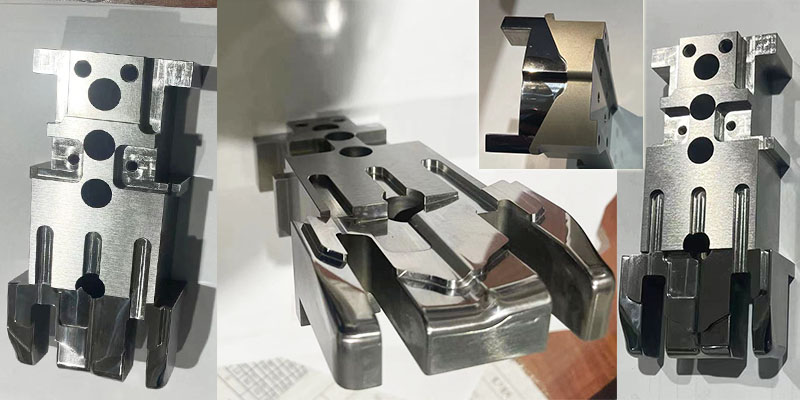

Customized CNC machining plays a crucial role in the manufacturing of precision parts with irregular shapes. Through precise CNC programming and advanced machining technology, it achieves precise control over the shape, size, and performance of components to meet personalized customer needs. In the customized processing of precision CNC components with irregular shapes, the professionalism and flexibility of CNC machining services are fully demonstrated.

Machining Processes

1.Design and CAD Modeling

Initial Concept: The process begins with a detailed design based on specific requirements. Engineers and designers collaborate to create a concept that meets functional, aesthetic, and performance criteria.

CAD Modeling: Using advanced CAD software, the concept is transformed into a 3D model. This model serves as the blueprint for the machining process, detailing every dimension and tolerance.

2. Material Selection

Criteria: The choice of material is crucial for the performance and durability of the component. Factors such as strength, weight, thermal properties, and corrosion resistance are considered.

Common Materials: Materials commonly used include aluminum, titanium, stainless steel, and specialized alloys, each selected based on the specific application of the component.

3. CNC Programming

Tool Path Generation: CNC programming involves generating tool paths that guide the machining tools to create the desired shape. This step requires precise calculations and simulations to ensure accuracy.

Software Utilization: CAM (Computer-Aided Manufacturing) software is used to convert CAD models into CNC-compatible code. The software optimizes the tool paths for efficiency and precision.

In addition, precision CNC parts with irregular shapes require special processing techniques and techniques. For example, for components with complex surfaces, five axis simultaneous machining technology can be used to achieve efficient and accurate machining. Advanced technologies such as high-speed cutting and laser processing can be used to improve the machining efficiency and quality of components with high hardness or difficult machining requirements.

Challenges and Countermeasures

1. Geometric Complexity

Challenge: Machining special-shaped components with intricate geometries can be challenging due to tool access and machining stability.

Solution: Using multi-axis CNC machines and custom fixtures can overcome these challenges, allowing for more flexible and accurate machining.

2. Material Properties

Challenge: Different materials pose various machining challenges, such as tool wear and heat generation.

Solution: Selecting appropriate cutting tools and optimizing machining parameters (speed, feed rate, and depth of cut) can mitigate these issues.

3. Precision and Accuracy

Challenge: Achieving and maintaining high precision and accuracy throughout the machining process is critical.

Solution: Regular calibration of machines, thorough quality control processes, and using advanced inspection tools ensure that the desired precision is achieved.

Future Development Trends

With the continuous development and technological progress of the manufacturing industry, the customized processing of special-shaped precision CNC parts will present the following trends:

Continuous improvement of precision and efficiency: With the continuous innovation of CNC machining equipment and technology, machining accuracy will continue to improve, and machining efficiency will be greatly improved.

Deepening the level of customization: With the continuous development of market demand and the increasing demand for personalization, customized CNC machining will pay more attention to personalized design and production to meet the needs of different customers.

Improvement of intelligence and automation level: through the introduction of intelligent manufacturing, industrial Internet and other technologies, the intelligence level and automation level of the processing process will be continuously improved, and the production efficiency and product quality will be improved.

Conclusion

Customized machining of special-shaped precision CNC components is a complex but essential process in modern manufacturing. It involves meticulous planning, advanced techniques, and continuous process optimization. By understanding the implementation steps and exploring various machining processes, manufacturers can produce high-quality, precision components that meet the exacting demands of various industries. The ability to create these unique parts drives innovation and allows for the development of cutting-edge products and technologies.