In today’s society, sustainable development has become the focus of attention in all walks of life, and manufacturing is no exception. Sustainable development covers the three fields of economy, society and environment, providing the key prerequisite for sustainable development of the manufacturing industry. Among them, CNC machining technology, as one of the core technologies of modern manufacturing, plays an important role in improving production efficiency, reducing energy consumption and reducing environmental pollution. This article will explore the importance and application of sustainability and CNC machining in green practices in manufacturing.

1. Efficient Use Of Resources

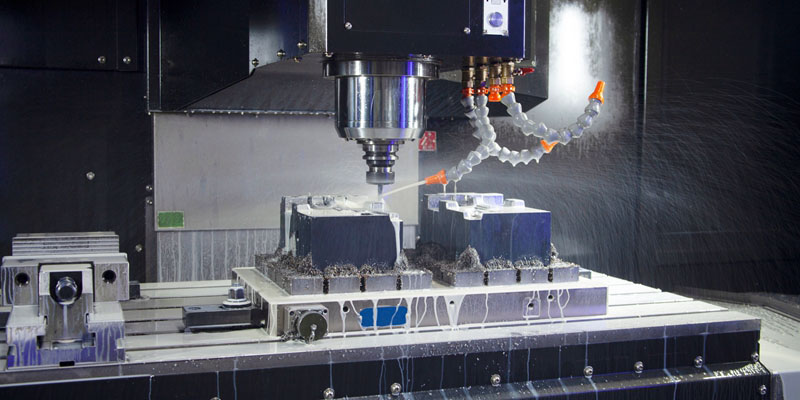

The concept of sustainable development is first reflected in the effective use of resources in CNC machining. As a high-precision and high-efficiency processing equipment, CNC machine tools can greatly reduce the waste of raw materials and improve the yield of finished products. At the same time, by optimizing process parameters and procedures, energy consumption, including electricity, water and other auxiliary materials, can be reduced. These measures can help reduce the manufacturing industry’s dependence on natural resources and achieve efficient use of resources.

In terms of efficient utilization of resources, some advanced CNC machining technologies have achieved remarkable results. For example, the use of advanced tool materials and coating technology can significantly improve the life and cutting efficiency of tools, thereby reducing the number and cost of tool replacement. In addition, raw material waste and energy consumption can be minimized by optimizing processing parameters and procedures. The application of these technologies not only improves production efficiency, but also saves costs for enterprises, which is conducive to promoting the sustainable development of the manufacturing industry.

2. Environmental Protection

In addition to the efficient use of resources, sustainable development is also reflected in environmental protection. Intelligent and automated processing of CNC machine tools can reduce manual errors, improve product quality and stability, thereby reducing the number of scraps and rework. In addition, environmental pollution during the production process can be reduced by using environmentally friendly technologies such as environmentally friendly materials and low-toxic coatings. These measures help reduce manufacturing’s carbon emissions and waste emissions, thereby reducing its impact on the environment.

In terms of environmental protection, some advanced CNC machining technologies have made important breakthroughs. For example, the use of water-soluble cutting fluids and dry cutting technology can reduce the use of cutting fluids and the generation of waste. In addition, by optimizing the cooling system and technical parameters, coolant usage and emissions can be reduced. The application of these technologies is not only beneficial to environmental protection, but also reduces production costs and improves economic benefits for enterprises.

3. Social Benefits

Sustainable development is also reflected in social benefits. The development of manufacturing industry needs to focus not only on economic benefits, but also on social benefits. By adopting CNC machining technology, production efficiency and product quality can be improved, thereby providing better products and services to meet people’s needs. At the same time, CNC machining can also create more job opportunities, improve the skill level of workers, and promote social progress and development.

In terms of social benefits, some advanced CNC machining technologies have achieved important results. For example, the use of flexible manufacturing technology and intelligent manufacturing technology can realize small batch and multi-variety production to meet the diverse needs of the market. In addition, by optimizing the production process and management model, production efficiency and delivery cycle can be improved, thereby providing better services to customers. The application of these technologies not only helps improve the competitiveness of enterprises, but also promotes the development of manufacturing and social progress.

4. Future Prospects Of Green Practices

With the advancement of science and technology and the development of society, green practices will play an increasingly important role in the manufacturing industry. In the future, the manufacturing industry will pay more attention to environmental protection and sustainable development, and will achieve zero pollution and zero waste in the production process by introducing more environmentally friendly technologies and methods. At the same time, as consumer demand for environmentally friendly products continues to increase, the manufacturing industry will pay more attention to the environmental performance and sustainability of products. As an advanced manufacturing technology, CNC machining will play a greater role in future green practices.

Conclusion

Sustainability and CNC machining play an important role in green practices in manufacturing. By using CNC machining technology, the effective utilization of resources, environmental protection and social benefits can be organically combined, and the sustainable development of the manufacturing industry can be promoted. In the future, with the advancement of science and technology and the development of society, green practices will play an increasingly important role in the manufacturing industry. The manufacturing industry will pay more attention to environmental protection and sustainable development, and consumer demand for environmentally friendly products will also continue to increase. In this process, CNC machining will play a greater role and provide more support and help for green practices in the manufacturing industry.

Excellent