In the manufacturing industry, reducing the scrap rate of machined parts is crucial, as it not only affects production efficiency, but also directly affects the cost and profitability of enterprises. Confirming the drawings to reduce the scrap rate of parts is an important task, which involves the efficiency and cost control of the production process. To achieve this goal, we need to take a series of measures.

1. Ensure The Accuracy And Completeness Of The Drawings.

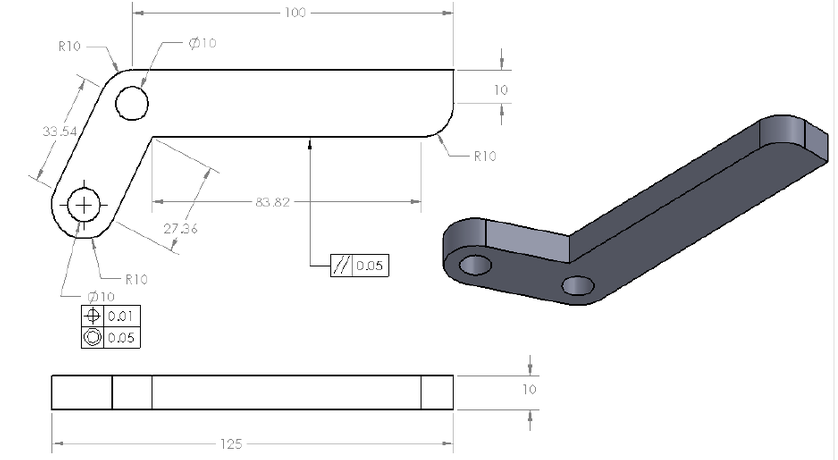

Drawing is a guiding document in the production process, which must clearly and accurately describe the size, shape, material, and process requirements of the parts. Any errors or omissions may result in the scrapping of parts. Therefore, before production, the drawings should be carefully reviewed to ensure that they meet the design requirements and are error free.

2. Confirm That The Version Of The Drawing Is The Latest Version Currently In Use

In fact, the drawings circulating in the workshop, especially those in the hands of operators, are likely not the latest versions because the design and improvement of part drawings is a continuous process of revision. Therefore, in the sales process of products, many parts still involve a large number of or advanced modifications. From the modification by R&D design engineers to the use of workshop operators, this is a relatively long operation process, The replacement of many drawings may not be timely or even overlooked. So as a machining worker, especially a process engineer on the machining site, it is essential to ensure the version update of the part drawings to the maximum extent possible, and confirm that the current drawing version used is the final part drawing version.

3. Confirm The Various Processing Requirements In The Drawings

For example, material, size requirements, behavior tolerance requirements, roughness requirements, heat treatment requirements, and so on, all of these information are very clear on the drawings. Of course, due to the design ability of the design engineer, there may be some omissions in these requirements. At this time, experienced mechanical process engineers are needed to check, such as thinking about the product drawings, assembly, and usage situation to a certain extent, Making up for the missing parts of the design engineer is actually a process of continuously improving the product.

4. Ensure Consistency Between 2D Drawings And 3D Files

Sometimes, 2D drawings exported from 3D may lack important data such as dimensions and tolerances. Due to different personal habits, workshop operators sometimes process based on 3D, while others process based on 2D. So ensuring consistency between 2D and 3D drawings can help reduce the scrap rate of part processing.

5. Confirm The Matching Of Drawings And Parts

In real production sites, such situations do exist, especially when many parts have similar designs or symmetrical layouts, it is easy to use the wrong drawings for processing, because the blank of the parts is the same. Originally, there were two drawings, but many people made one, and different parts were also processed into two parts.

Drawing is an important reference for part processing and later inspection, ensuring the accuracy of order drawings and the feasibility of order drawing design, which can greatly reduce the scrap rate of parts and lower costs.