CNC machining has long been associated with large manufacturing operations due to its high initial investment costs and the expertise required to operate sophisticated machinery. However, as technology evolves, CNC machining has become increasingly accessible to small businesses, enabling them to compete on a level playing field with larger companies. In this post, we’ll explore how CNC machining is revolutionizing small business manufacturing, the benefits it offers, and how small enterprises can leverage this technology to enhance their competitiveness.

Understanding CNC Machining

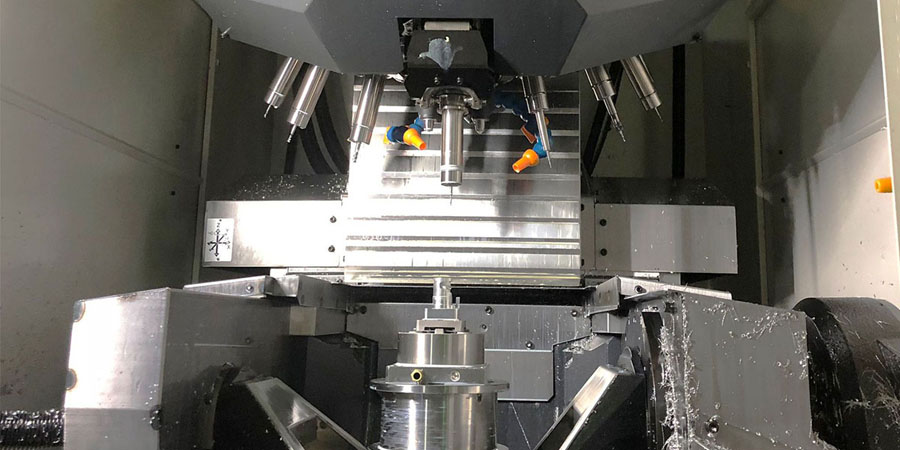

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. This automation allows for precise control over the machining of complex parts, leading to high-quality, consistent results. The process is used for a variety of materials, including metals, plastics, wood, and composites, making it versatile across numerous industries.

Benefits of CNC Machining For Small Businesses

Cost-Effective Production

One of the main advantages of CNC machining is its ability to produce parts cost-effectively, even in small quantities. Traditional manufacturing often requires expensive tooling and setup costs, which are not economically viable for low-volume production. CNC machining eliminates many of these costs by using digital files to control the machinery, making it ideal for small businesses that need to produce small batches or custom parts.

High Precision and Consistency

CNC machines operate with high precision, which is crucial for producing parts that meet exact specifications. This level of accuracy reduces waste, ensures quality, and minimizes errors that can occur with manual machining. For small businesses, this means fewer costly reworks and the ability to deliver products that meet the highest standards of quality.

Flexibility And Rapid Prototyping

CNC machining offers unparalleled flexibility in design and production. Small businesses can quickly adjust designs and iterate on prototypes without significant delays or costs. This rapid prototyping capability allows for faster product development cycles, enabling small businesses to bring new products to market more quickly and respond to customer needs with greater agility.

Reduced Labor Costs

With CNC machining, much of the manufacturing process is automated, reducing the need for skilled labor. This can be a significant cost-saving for small businesses, as hiring and training skilled machinists can be expensive and time-consuming. Automation also means that small businesses can run production with fewer employees, allowing them to scale operations without a proportional increase in labor costs.

Scalability

As small businesses grow, CNC machining can easily scale to meet increased production demands. Because the same equipment can be used for both small and large production runs, there’s no need for significant reinvestment in machinery. This scalability ensures that small businesses can expand their offerings without being constrained by manufacturing capabilities.

Access to Advanced Manufacturing Techniques

CNC machining allows small businesses to access advanced manufacturing techniques that were once the domain of large corporations. Techniques such as 5-axis machining, which allows for the creation of highly complex geometries, or CNC turning for cylindrical parts, open up new possibilities for product design and innovation.

Challenges and Considerations

While CNC machining offers numerous benefits, small businesses must consider a few challenges:

Initial Investment:

Although costs have decreased, CNC machines still require an initial investment that may be significant for some small businesses. However, financing options, leasing, and outsourcing to CNC service providers can mitigate these costs.

Training and Expertise:

Operating CNC machinery requires a certain level of expertise. Small businesses may need to invest in training or hire skilled operators to fully leverage the technology.

Maintenance and Upkeep:

CNC machines require regular maintenance to operate efficiently. Small businesses must be prepared to handle the maintenance needs to avoid downtime and ensure consistent production quality.

Strategies For Small Businesses To Leverage CNC Machining

Outsourcing To CNC Machining Service Providers

For small businesses not ready to invest in CNC equipment, outsourcing to a CNC machining service provider can be a cost-effective solution. This approach allows businesses to access high-quality CNC machining without the need for capital investment in equipment or specialized staff.

Investing in Multi-Purpose Machines

If purchasing CNC machines, small businesses should consider versatile machines that can handle a variety of tasks. Multi-axis machines, for example, can perform milling, drilling, and cutting in a single setup, reducing the need for multiple machines and simplifying the production process.

Embracing Digital Manufacturing Solutions

Small businesses can maximize the benefits of CNC machining by embracing digital manufacturing solutions. Utilizing CAD (Computer-Aided Design) software and CAM (Computer-Aided Manufacturing) software can streamline the transition from design to production, making the manufacturing process more efficient and responsive.

Focusing on Niche Markets

CNC machining allows small businesses to produce highly specialized parts that may not be feasible for larger manufacturers due to low volume. By focusing on niche markets or custom parts, small businesses can carve out a competitive advantage and build a loyal customer base.

Conclusion

CNC machining has become a game-changer for small businesses, providing access to advanced manufacturing technologies that were once out of reach. By leveraging CNC machining, small enterprises can improve product quality, reduce costs, and enhance their ability to innovate. Whether through investing in their own CNC equipment or outsourcing to experienced providers, small businesses have the opportunity to level the playing field and compete effectively in today’s dynamic market landscape.

CNC machining isn’t just for the big players anymore—it’s a powerful tool that can help small businesses thrive and grow.