In the world of CNC machining, precision and quality are the pillars upon which successful manufacturing is built. From the aerospace industry to medical devices, quality control in CNC machining is essential to ensure that every component meets the strict tolerances, specifications, and standards required by these industries. Without a proper quality control system, even minor deviations can result in costly mistakes, component failure, or product recalls.

This post explores the best practices and standards that can help ensure quality control in CNC machining and how companies can implement them to maintain high levels of precision, reliability, and performance.

Why Quality Control is Important in CNC Machining

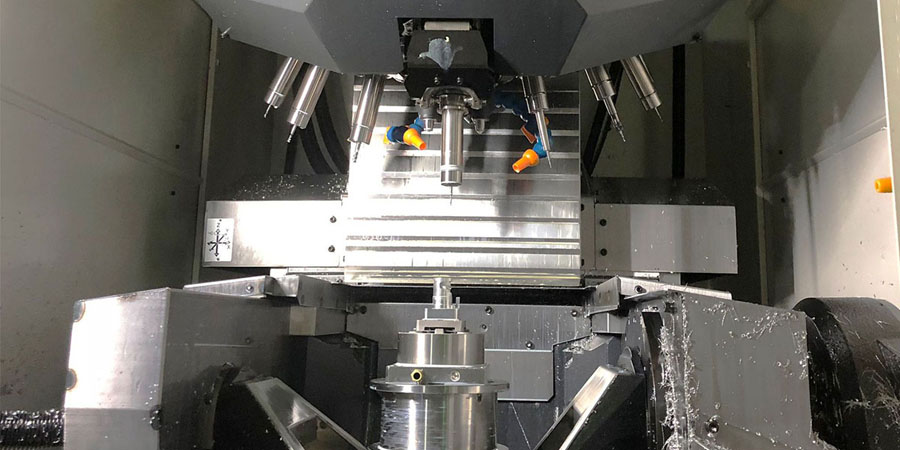

CNC (Computer Numerical Control) machining is a process that involves the use of computers to control machine tools. These machines are highly accurate and capable of creating complex parts with tight tolerances. However, the human factor, environmental conditions, machine maintenance, and material inconsistencies can introduce variations that affect the overall quality of the final product.

Implementing a strong quality control system ensures that:

– Tolerances are met consistently: Tight tolerances are crucial in CNC machining, especially for parts that must fit together perfectly or perform under extreme conditions.

– Reduction of defects: By identifying and addressing potential issues early in the process, defects are minimized or eliminated.

– Increased efficiency and reduced waste: Proper quality control reduces material waste and production time by preventing rework and delays due to non-conforming parts.

– Enhanced customer satisfaction: Consistent quality results in products that meet or exceed customer expectations, helping to build trust and brand reputation.

Best Practices for Ensuring Quality Control in CNC Machining

- Clear Communication of Specifications

One of the most critical elements of quality control is clear communication between the client and the machining provider. Every part that undergoes CNC machining comes with a set of specifications, tolerances, and finishing requirements. These must be clearly documented, including the type of material, surface finishes, dimensions, and more.

Detailed CAD drawings and 3D models should be provided with the necessary dimensional data and annotations. This helps the machinist understand the client’s requirements precisely, reducing the risk of errors or misinterpretation.

- Regular Calibration and Maintenance of Machines

For CNC machines to maintain their accuracy and precision, they must be regularly calibrated and maintained. Regular maintenance schedules should be followed to ensure that the machines are functioning correctly. Any deviation in machine accuracy can have a direct impact on the quality of the parts produced.

Additionally, tools used in the machining process, such as cutting tools, drills, and end mills, should be inspected and replaced as needed. Worn tools can lead to poor surface finishes and dimensional inaccuracies.

- In-Process Monitoring and Inspection

One of the best ways to ensure consistent quality is to conduct in-process inspections during machining. Rather than waiting until the end of the production run, parts should be inspected at different stages of the machining process. This can be done using a combination of visual checks, dimensional measurements, and specialized inspection tools.

In-process monitoring helps to catch defects early and allows for adjustments to be made to the process in real-time. This reduces the likelihood of producing non-conforming parts and minimizes material waste.

- Implementing Statistical Process Control (SPC)

Statistical Process Control (SPC) is a method of using statistical techniques to monitor and control production processes. It helps in detecting variations in the machining process that may affect quality. By collecting data on critical dimensions and using control charts, manufacturers can monitor trends and deviations from the desired specifications.

SPC enables manufacturers to take corrective actions proactively, preventing defects before they occur. It’s an essential tool in maintaining high-quality standards throughout production.

- Use of Coordinate Measuring Machines (CMM)

Coordinate Measuring Machines (CMMs) are critical tools for inspecting parts after CNC machining. CMMs use precise probing to measure the dimensions of machined parts accurately. They are particularly useful for checking complex geometries, tight tolerances, and parts with intricate features.

By using a CMM for final inspection, manufacturers can ensure that every part meets the exact specifications required. This level of precision helps maintain consistency and reduces the chances of sending non-conforming parts to customers.

- Material Verification and Traceability

In many industries, the type of material used for machining is as important as the machining process itself. For example, in aerospace and medical applications, specific metals or alloys may be required due to their strength, durability, or corrosion resistance.

To ensure quality control, manufacturers must verify the materials they receive from suppliers and maintain traceability throughout the production process. Material certificates and documentation should be cross-checked, and material properties should be tested as needed.

- ISO Standards for CNC Machining

Adhering to international standards is one of the best ways to ensure consistent quality control. ISO 9001 is a widely recognized quality management system standard that outlines requirements for a systematic approach to controlling production processes and ensuring quality.

CNC machining providers that are ISO 9001 certified follow a set of procedures that help in preventing errors, monitoring performance, and making improvements when necessary. Other standards, such as AS9100 (for aerospace) or ISO 13485 (for medical devices), may also be applicable depending on the industry.

- Employee Training and Expertise

Quality control is not just about machines and tools; it also depends on the expertise of the operators and engineers running them. Well-trained machinists and quality control personnel are essential to maintaining high standards. Continuous training on the latest CNC technology, quality control techniques, and safety practices should be part of a company’s quality management strategy.

Ensuring that operators are familiar with the materials, machine settings, and tolerances required for specific parts can prevent many potential issues before they arise.

Conclusion

Ensuring quality control in CNC machining is an ongoing process that requires attention to detail, regular monitoring, and adherence to industry standards. By implementing best practices such as clear communication, regular machine calibration, in-process monitoring, and adherence to ISO standards, manufacturers can maintain high levels of precision and reliability in every part they produce.

In a competitive market, companies that invest in quality control not only reduce costs associated with defects and rework but also build long-term trust with their customers, ensuring continued success and growth in the CNC machining industry.