Ultrasonic cleaning uses high-frequency sound waves, those beyond the normal human hearing range, and appropriate cleaning solvents to remove contaminants from parts. Ultrasonic waves can be used to clean a wide range of items, including automotive parts, medical devices, jewelry, dental instruments, eyeglasses, and more.

How Does An Ultrasonic Cleaning Machine Work?

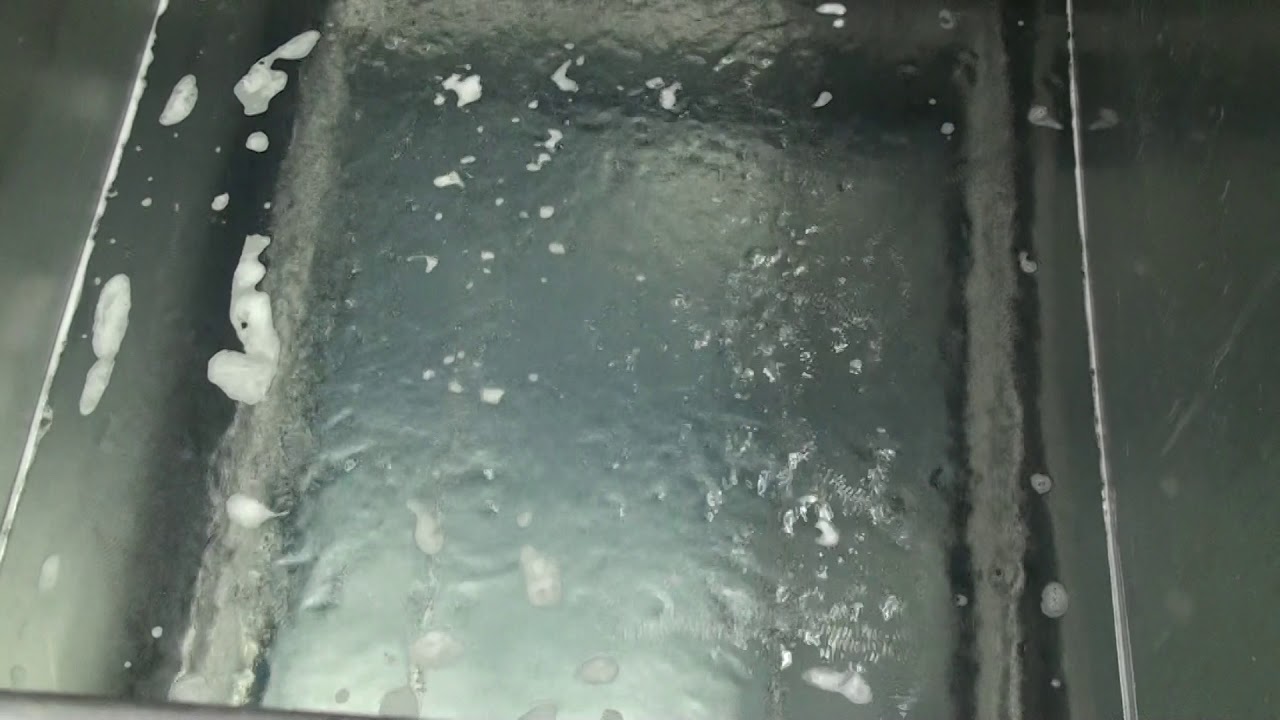

Ultrasonic cleaning is a combination of spray cleaning and immersion cleaning. After soaking the parts in the cleaning machine, the transducer installed on the cleaning machine will generate sound waves and transmit them throughout the entire cleaning machine. At the same time, the sprayer sprays water onto your components. Sound waves help generate bubbles in the sprayed water, which collide with the surface of the parts. When bubbles come into contact with the hard surface of the component to be cleaned, they will implode into micro jets. Jet removes unwanted particles from the surface of parts at relatively high pressure, temperature, and velocity Ultrasonic cleaning machines can clean various materials. This includes metal, glass, rubber, ceramics, and hard plastics.

Due to the very small size of bubbles, ultrasonic cleaning is a very gentle process. Moreover, due to the fact that bubbles can cover the entire surface of the part and even penetrate the smallest cracks, crevices, blind holes, threads, and other features, ultrasonic cleaning is an effective method for cleaning the inside and outside of the entire part.

What Are The Benefits Of Ultrasonic Cleaning?

Ultrasonic cleaning is unique in effectively cleaning components and reaching all surfaces and blind holes. In short, this cleaning method is becoming increasingly popular and suitable for items that are too delicate, complex, or difficult to clean using traditional methods.

Save Costs And Time

Due to the use of agitation and removal of dirt and oil stains in this method, certain components (such as O-rings) can be left in place, thereby saving costs. Ultrasonic cleaning can also improve technical productivity. Ultrasonic cleaning machines can also clean multiple components at once faster than other methods.

Multi Functional Cleaning

There is no component that is too complex, challenging, or delicate to undergo ultrasonic cleaning. Due to the use of sound waves in this method, your cleaning solution can penetrate all surfaces and hidden channels. In addition, if adjusted correctly, this method can also remove pollutants without causing wear and tear. This versatility makes them an ideal choice for cleaning microchips and computer components. In addition, they are suitable for the food, cosmetics, medical, and pharmaceutical industries. They can effectively remove mold and bacteria, thoroughly cleaning your components.

Removes Stubborn Contaminants

Ultrasonic cleaning can effectively remove a wide variety of contaminants, including grease, oils, dust, dirt, and oxidation.

Environmentally Friendly

Ultrasonic cleaning often requires fewer or less harsh cleaning agents than traditional methods, making it more environmentally friendly.

The cleaning process generates minimal waste, as it relies on water-based solutions rather than solvents.

By adopting ultrasonic cleaning, businesses can enhance product quality, improve operational efficiency, and promote a safer working environment.

Our professional technology and high-quality service have gained increasing recognition and trust from more and more customers. We can provide customers with cost-effective cleaning equipment and solutions, and ensure timely production of orders.