In today’s fast-paced and highly competitive industrial landscape, precision component manufacturing plays a crucial role across various sectors, including aerospace, automotive, medical devices, electronics, and more. Precision components are defined by their tight tolerances, intricate designs, and exceptional quality, which are essential for the overall functionality and performance of the final products.

Precision component manufacturing is an integral part of every industry that helps businesses gain both time and money savings and, most importantly, has a strong reputation for quality. In this post, we will explore what precision component manufacturing entails and why it is vital for various industries.

What Is Precision Component Manufacturing?

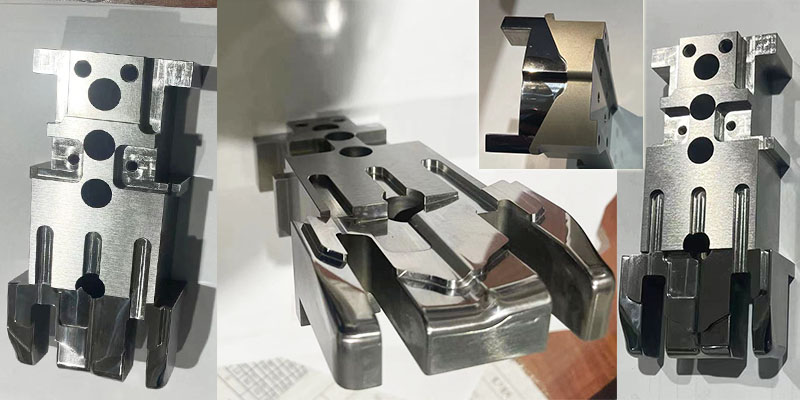

Precision component manufacturing refers to the process of producing parts and components with extremely tight tolerances, often measured in micrometers. This process involves advanced machining techniques, including Computer Numerical Control (CNC) machining, 3D printing, and precision molding, among others. The goal is to achieve a high level of accuracy and repeatability in the production of parts that meet specific design specifications and functional requirements.

Precision components can be made from various materials, including metals (like stainless steel, aluminum, and titanium), plastics, and composites. The choice of material depends on the application, environmental factors, and the desired mechanical properties of the final product.

Importance of Precision Component Manufacturing

Precision is a necessity when it comes to manufacturing automotive, aerospace, electronic, and health-related products. The Final -product has to be safe, perform well, and be reliable. Utilizing the most sophisticated technologies like CNC machining, they manufacture critical components to the maximum extent of precision, and it becomes feasible for every component to adhere to rigid standards.

Quality And Reliability

One of the primary reasons precision component manufacturing is critical is the need for quality and reliability in the final product. Components with tight tolerances ensure that each part fits correctly and functions as intended. In industries such as aerospace and medical devices, even the slightest deviation in dimensions can lead to catastrophic failures, compromised safety, or costly recalls. Precision manufacturing helps mitigate these risks and enhances the reliability of the products.

Performance Optimization

Precision components often enhance the overall performance of the systems they are part of. For instance, in automotive applications, precision-engineered parts can lead to better fuel efficiency, improved handling, and greater durability. In electronics, precision components ensure optimal electrical conductivity and signal integrity, which are essential for the proper functioning of devices.

Cost Efficiency

While precision component manufacturing may involve higher initial costs due to advanced technologies and skilled labor, it can lead to significant cost savings in the long run. By producing high-quality components that require less rework, fewer replacements, and minimal maintenance, companies can reduce their overall production costs. Additionally, improved efficiency and performance can lead to savings on operational costs.

Customization and Innovation

In a world where customization is increasingly demanded by consumers, precision component manufacturing allows for the creation of bespoke parts tailored to specific requirements. This capability fosters innovation and enables companies to differentiate their products in the market. Whether it’s designing lightweight components for aerospace or unique geometries for medical implants, precision manufacturing provides the flexibility needed to bring innovative ideas to life.

Adherence to Regulatory Standards

Many industries are governed by strict regulatory standards that mandate specific requirements for components and materials. Precision component manufacturing ensures compliance with these regulations, which is essential for obtaining necessary certifications and approvals. For instance, the medical and aerospace sectors require components to meet stringent quality and safety standards, making precision manufacturing indispensable.

Enhanced Competitive Advantage

Companies that invest in precision component manufacturing often gain a competitive edge over their rivals. By producing high-quality components consistently, these companies can enhance their reputation, build customer loyalty, and capture a larger market share. In industries where performance and reliability are paramount, having a reputation for excellence can significantly influence purchasing decisions.

Conclusion

Precision component manufacturing is not just a technical process; it is a critical component of modern engineering and product development. Its importance spans multiple industries, driving quality, performance, and innovation. As technologies continue to advance, the demand for precision components will only increase, highlighting the need for manufacturers to invest in precision capabilities to remain competitive in the evolving market landscape. Whether it’s ensuring safety in aviation or improving the effectiveness of medical devices, precision component manufacturing is essential for delivering high-quality products that meet the rigorous demands of today’s consumers and industries.