CNC milling is one of the most impressive technologies of this century. Due to the reliability and versatility of CNC milling, the technology has rapidly expanded into new industries such as musical instrument manufacturing, electronics industry, medical treatment, and automobiles. This is an ideal method for rapid prototyping and mass production of plastics and metals. Although most CNC milling is suitable for metal processing, these tools are extremely versatile and can produce customized precision parts for various industries.

Even though the process and use of CNC milling are well known to those in the industry, people outside may not be familiar with its application and even how it works.

Therefore, we will study milling in depth, focusing on various aspects of the process itself and machinery. This will help you understand whether you need CNC milling services to produce parts.

What Is CNC Milling

People often request CNC machining when looking for milling. Machining is divided into milling and turning, but there is a clear difference between the two. Mechanical machining refers to mechanical cutting technology, which uses a variety of tools to remove material through physical contact. CNC milling is one manufacturing method that uses a computer numerical control system to automate the process.

Before the advent of computing technology, milling was performed manually or Mechanically operated. Nowadays, it is carried out by computer numerical control milling machine. CNC milling computer numerical control milling) is a processing process that uses computer control and rotary cutting tools to gradually remove material from the workpiece and produce custom-designed parts or products.

These machine are called machining centers, and they are horizontal or vertical according to the direction of the cutting tool spindle. A machining center consists of a tool magazine, turntable, automatic tool change system, computer control, housing and coolant. Now milling is integrated with turning and vice versa, which can provide greater flexibility and increase productivity. The process is suitable for machining various materials, such as metal, plastic, glass and wood, and producing various custom-designed parts and products.

Computer-controlled CNC can achieve unparalleled accuracy, and convert specific digital codes into Cartesian coordinates, thereby ensuring that each part is produced with absolute accuracy to the smallest detail, which is almost impossible to perform manually.

For the production of precision parts, CNC milling is indeed unmatched. Assure buyers of the extremely high precision of CNC milling parts, which is unmatched by traditional milling methods. Part production can provide a high degree of repeatability, whether it is a single part or multiple parts, can provide high quality, precise accuracy.

CNC Milling Process

Like most traditional mechanical CNC machining processes, the CNC milling process uses computer control to operate and manipulate machine tools that can cut and shape raw materials. In addition, the process follows the same basic production stages of all CNC machining processes, including:

Design 2D or 3D CAD models

Convert CAD Model to CNC Program

The program can be used to check and modify (if necessary) to suit the machine’s function. Moreover, manufacturing engineers can use this software to simulate the entire cutting process.

This allows you to check for errors in the design and avoid creating models that cannot be produced.

The program can also be written manually as in the past. However, this greatly lengthened the entire process. Therefore, we recommend making full use of the possibilities offered by modern engineering software.

Set up CNC Milling Machine

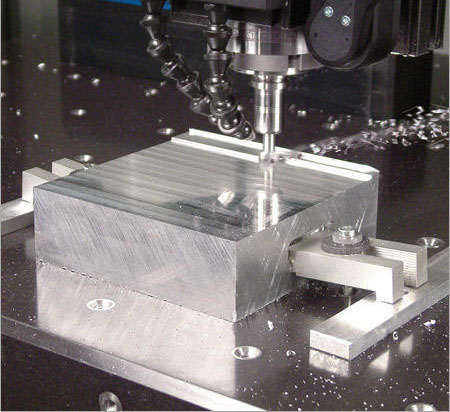

Although the CNC machine does the cutting work automatically, many other aspects of the process still require the help of the machine operator. Fix the work piece to the working surface of the machine tool (ie worktable) or work piece fixture (such as a vice), and then install the milling tool on the machine tool spindle.

After the initial setup is complete, the operator checks the machine program for the last time, and then causes the machine to turn on the green light.

Perform milling operations

The milling process uses a rotating tool that comes into contact with the workpiece to swarf. Once the CNC milling process is initiated, the machine tool begins to rotate and cut at a speed of up to several thousand RPM to produce the desired shape. Milling uses cylindrical cutting tools that can rotate in different directions. Unlike traditional drilling, the cutter can move along multiple axes. It also has the ability to create various shapes, slots, holes and other necessary impressions. In addition, the workpiece of the CNC milling machine can be moved across the cutter in a specific direction.

CNC Milling Operations

CNC Milling Operations

CNC Milling is suitable for many different functions, including thread, chamfers, slotting,pockets, etc. This allows complex designs to be produced with enviable precision on a single CNC milling center. The tolerance is about +/- 0.1 mm. SANS high precision tolerance within +/-0.003mm. The most common CNC milling operations include:

- Face Milling

- Surface Milling

- Angular milling

- Form milling

- Face milling

Face Milling

Face milling refers to milling operations in which the axis of rotation of the cutting tool is perpendicular to the surface of the workpiece. This method uses an end face cutter, which has teeth on both the outer periphery and the tool surface. The outer periphery teeth are mainly used for cutting, while the end teeth are used for finishing, and are responsible for the surface finish. Generally, face milling is used to create flat surfaces and contours on finished parts, and can produce higher quality finishing than other milling processes.

The types of face milling include end milling and side milling, which use end mills and side mills, respectively.

Surface Milling

Plain milling, also known as surface or slab milling. It uses a horizontal milling cutter and the rotation axis of the cutting tool is parallel to the surface of the workpiece. Depending on the necessary results, it is possible to use wide or narrow surface tools for surface milling.

Depending on the specifications of the milling application, narrow and wide knives can be used. Narrow knives can make deeper cuts, while wide knives can be used to cut larger surface areas. When using wider knives, slow cutting speeds and fast feed speeds produce the approximate geometry of custom designed parts.

Of course, the surface finish of this cut may not meet the requirements. The operator then introduced finer toothed cutters, faster cutting speeds and slower feed speeds to produce more accurate details of the finished part. Therefore, from an economic perspective, the combination of the two is a good choice.

Angular Milling

Angular milling, also known as angle milling. Through this milling operation, the rotation axis of the cutting tool is at a certain angle with respect to the workpiece surface, we can create chamfers, grooves, etc.

Use a single-angle milling cutter (the angle is determined based on the specific design being processed) to produce angular features such as chamfers, saw teeth, and grooves. A common application of angle milling is the production of dovetails, which use 45°, 50°, 55° or 60° dovetail tools according to the design of the dovetail.

Form Milling

Form milling refers to milling operations involving irregular surfaces and contours. Special tools are required to produce more complex surface contours. Convex, concave and round chamfering knives are all examples of tools used here. These tools can help create circular grooves, circular edges, etc., such as parts with complex designs with curved and flat surfaces or fully curved surfaces. These tools must have the correct parameters to achieve the desired results.

Profile Milling

A common milling operation, the machine tool creates a cutting path on the vertical or inclined surface of the workpiece. This process uses contour milling equipment and cutting tools, which can be parallel or perpendicular to the workpiece surface, used to produce convex and concave parts. The process includes 3 steps-roughing, semi-finishing and finishing.

Such work will greatly benefit from CNC milling, because 4-axis and 5-axis technology can greatly speed up the operation and provide higher quality.

Other Milling Operations

In addition to the above operations, the milling machine can also be used to complete other specialized milling and machining operations. Examples of other types of milling machine operations available include:

Straddle milling: Straddle milling refers to milling operations in which the machine tool processes two or more parallel workpiece surfaces in one cut. This process uses two tools on the same machine tool mandrel, which are arranged so that the tools are located on either side of the workpiece and both sides can be milled simultaneously.

Gang milling: Gang milling refers to the use of two or more tools (usually tools of different sizes, shapes or widths) on the same machine spindle. Each cutter can perform the same cutting operation or different cutting operations at the same time, thereby producing more complex designs and complex parts in a shorter production time.

Gear milling

Yes, milling can also be used to produce gears. The first is gear milling. The flexibility of the material makes it easier to manufacture parts, while achieving large tolerances. Then, the gear undergoes a heat treatment process to harden the surface. After that, CNC turning will be responsible for the final result.

CNC Machining Advantages

Like other types of computer numerical control used in machining applications, CNC milling has the following advantages

Like other types of computer numerical control used in machining applications, CNC milling has the following advantages

High Precision

Whether you are producing an initial prototype or final product, you can rest assured that the project will match the dimensions specified in the CAD or CAM file. Such high accuracy can bring you many advantages, including increased productivity and reduced material waste. It also maximizes the cost of processing hardware.

The extremely high accuracy and precision of CNC milling makes it used in the fields of aerospace and medicine, which need to perform every detail without any error.

Versatility

The availability of vertical and horizontal CNC milling machines and multi-axis CNC milling centers provides excellent versatility. As a result, they can accurately process projects with various complexity and parameters.

High Reproducibility

No matter how you apply CNC, whether it is turning, turning or drilling, you can rely on the machine to produce products based on CAD or CAM files every time. This brings benefits similar to those provided by CNC milling center accuracy, such as reduced waste and increased efficiency.

High Efficient

Because CNC milling machines can actually be run on an autopilot and do not require much human involvement, they can run continuously for several days without downtime, thereby consistently producing parts with the same accuracy. The automated process on which CNC milling is based also means that fewer people are required to monitor and operate it, which not only improves efficiency, but also reduces production costs.

Only a few skilled experts are required to supervise the entire process, which means higher cost efficiency for the end customer.

Advanced Possibility

Thanks to advanced automation software and design software, even if the manufacturing process itself is similar, CNC milling machines can outperform the most skilled technicians who operate manual machines.

This not only means better consistency and the elimination of human errors, but also means that it is possible to produce much more complex designs with different sizes, shapes and even textures.

High Consistency

Since the process behind CNC milling is mostly automated, it can produce excellent consistency even if the person managing the tool changes.

Once the master file of the design has been created, it can be used to create an unlimited number of copies, all of which have the same quality without any deviation. Each part will perfectly match the previous version, even for the most skilled manual operator

CNC Machining Application

Because CNC machines have extremely high precision, it is understandable why they are widely used in the aerospace industry, where the technology plays a crucial role in producing various parts used to ensure the safety and normal function of aircraft Important role.

CNC machining also plays a vital role in the field of medical technology because it allows the use of multiple grades of titanium and stainless steel to manufacture parts and tools that are commonly used to make scalpels, medical equipment, and implants.

With the advancement of CNC technology, making it cheaper and more reliable, it has been more and more widely used in consumer products, such as electronic products or sports equipment, especially for parts requiring precision and combining metal and plastic materials .

Inquiry Now!For the production of precision parts, CNC milling is indeed unmatched. Whether it is a single part or multiple parts, SANS can provide high quality, precise accuracy products. We specialize in custom CNC machining service for more than 10 years. No MOQ. Get Free Quote Now!