Centerless grinding is the outer diameter grinding process, sometimes we call it OD grinding. Centerless grinding is a process used to remove material from a workpiece and is usually used for operations that must process many parts in a short time.

What is Centerless Grinding?

In centerless grinding, the workpiece is fixed between two grinding wheels, rotating in the same direction and at different speeds. A grinding wheel rotates on a fixed shaft to reduce the force applied to the workpiece. The grinding wheel usually performs the grinding action by having a higher linear velocity at the contact point than the workpiece.

The other movable wheel is positioned to apply lateral pressure to the workpiece and usually has a rough or rubber-bonded abrasive to capture the workpiece. The relative speed of the two wheels provides the grinding effect, and the speed of the rotating grinding wheel depends on the speed at which material is removed from the workpiece. Centerless grinding is the process of removing material from the outer diameter of a workpiece using a grinding wheel.

The workpiece is located on its outer diameter and supported by a working blade located between the adjusting wheel and the grinding wheel. The adjustment wheel drives the machined parts, and the grinding wheel removes material.

Types of Centerless Grinding Process

There are three types of centerless grinding. The main difference lies in the method of feeding the workpiece through the machine tool.

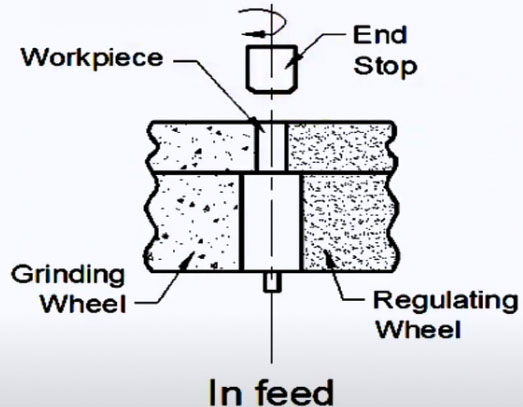

In-feed Grinding

The workpiece can have an independent outer diameter over the entire length, and the improved grinding wheel can be used to grind each part of the workpiece or crush the entire workpiece. Plunge feed can do feed centerless grinding, so any profile can be produced. This is useful if the workpiece has obstacles that do not allow it to pass through the grinding wheel. Obstacles may be shoulders, heads, circles, etc.

Feed centerless grinding can grind relatively complex shapes, such as hourglass shapes. Before the process starts, the workpiece is manually loaded into the grinder and the adjusting wheel is moved into position. The complexity required to accurately grind the shape of the part and the shape of the grinding wheel prevents the workpiece from being fed axially through the machine tool.

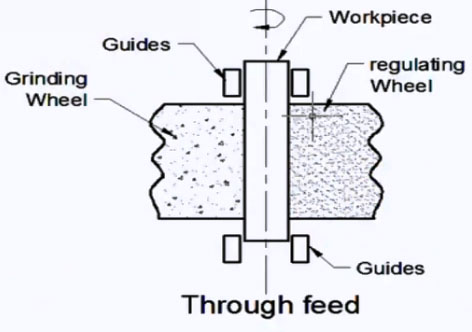

Thru-feed Grinding

In centerless feed-through grinding, the workpiece is fed completely through the grinding wheel, entering from one side and leaving from the other side. The adjustment wheel in straight-forward grinding is inclined away from the grinding wheel plane to provide an axial force component, thereby sending the workpiece between the two grinding wheels. Straight feed grinding is very effective because it does not require a separate feed mechanism. However, it can only be used for parts with simple cylindrical shapes.

The straight-through grinding workpiece can be larger than the grinding wheel, many workpieces can be ground at the same time in the equipment, and a larger output can be obtained.

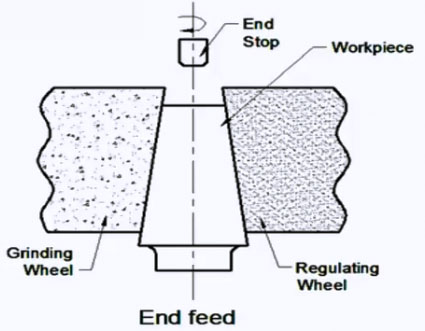

End-feed Grinding

In the end feed of centerless grinding, the workpiece is axially fed into the machine tool along one side and rests on the end stop. Perform the grinding operation, and then feed the workpiece in the opposite direction to exit the machine tool. ) Face feed grinding is most suitable for tapered workpieces.

Benefits of Centreless Grinding

The loading and unloading of the workpiece is easy

The loading or unloading of workpieces is simple and easy to automate. When using continuous straight-forward grinding, it will not waste time to replace the workpiece

Fast processing saves manufacturing time

Traditional cylindrical grinders need to cut multiple times to process the same part due to the limited width. The centerless grinder can process 200 to 300 parts per minute at an amazing speed (the exact number depends on the size of the part). The amazing design of the centerless grinder allows you to run hundreds of parts without manual intervention.

Less loading time

By using a centerless grinder, your loading time can be minimized to three seconds per part even when running in feed mode. Compared with centering grinding, centerless grinding can significantly shorten the loading time, to achieve almost uninterrupted grinding.

Can handle a large number of parts

If you want to process a large number of small cylindrical parts, a centerless grinder is a machine you need. Because the grinder does not require you to reset every part. Even if you need to machine parts with different diameters, don’t worry-the centerless grinder can handle multiple diameters with just a few changes.

A centerless grinder can be set up quickly

After setting the machine to a specific part, the OD size can be maintained with minimal operator intervention. After setting up a centerless grinder, the entire production process can usually be completed without resetting. This not only saves time and labor costs but also reduces the possibility of errors.

Persistent Wheel

Most centerless grinders have a diameter of 24 inches and a maximum width of 24 inches. A usable grinding wheel with a diameter of 17 inches can grind thousands of finished parts with a set of grinding wheels. As the center error is eliminated, the part is in a “floating” state, thereby reducing tolls and extending the service life of the wheels.

Tight Tolerance

Centerless grinding can maintain tighter dimensional tolerances.

No Deflection:

Because the workpiece is fully supported, it is possible to use heavier grinding than centering grinding.

Wide processing range:

Since there is no additional pressure on both ends of the workpiece, the centerless grinder is very suitable for processing fragile workpieces and fragile materials.

By supporting the workpiece linearly, it is also possible to grind soft or fragile materials because these machines operate through a low-tension process. There is no need to prepare a fixed workpiece for the grinder, thereby eliminating the failure caused by fixation. Also, smaller machines can handle long workpieces.

Application Of Centerless Grinding

Centerless grinders can process parts include shafts, balls, bearings, bolts, bushings, camshafts, carbide rods, compressor shafts, profile rollers, cylinders, drills, gear shafts and hubs, injector needles, injector plunger and valve body, isolator, motor shaft, needle, pin, piston pin, pivot, rotor, shaft, small crankshaft, spool, tube, valve lifter, valve piston, and valve stem.

Centerless grinding is used in many industries, such as automotive, aerospace, aerospace, bearings, consumer products, glass, medical, and tools and molds.

Heart grinding is essential for manufacturing many high-volume auto parts. These include spools, control rods, camshafts, crankshafts, pistons, sleeves, and rollers.

Besides, centerless grinding can manufacture parts for hydraulic and fluid control, medical and aerospace industries, in fact, any industry that requires cylindricity and cylindrical surface accuracy.

(Related Post: Types And Characteristics Of Surface Grinding What Is Precision Grinding?)

What a fantastic article! There are no risks of deflection with centerless grinding. The loading time is exceptionally short and the wheel life is long. The most brittle materials can also be well-grinded with this method. You may also enjoy a tight dimensional tolerance.