When you need to order one type of mechanical CNC parts, you need product quotations from multiple suppliers and choose the best one to start your project. The decision may be affected by CNC machining cost, delivery time, delivery time and quality.

In order to ensure that you get an accurate quotation, manufacturing suppliers will need your information to ensure that they can accurately produce the parts you expect and provide accurate estimates.

When requesting a quotation, in order to ensure a fast, reliable and accurate estimate of the price of a manufacturing partner, please prepare the following 5 things.

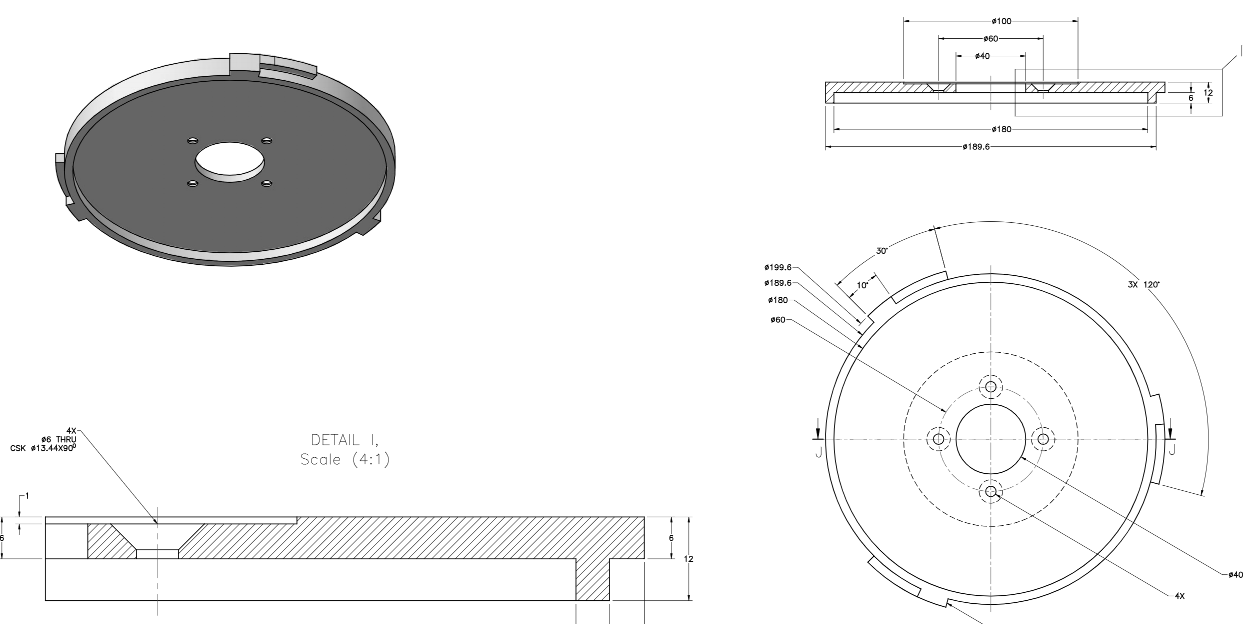

1. Design Drawings

As a general quotation, relevant documents are indispensable. It is used to identify clear requirements, such as product definitions, delivery requirements, etc. In CNC machining services, product design is the basis of CNC quotation. CNC machining parts usually have high precision and accuracy. In order to produce final parts with precise shapes and sizes, please submit 2D and 3D engineering drawings at the same time.

2D engineering drawings can specify product dimensions (length, width, diameter), tolerances, surface textures and more features to be processed, and 3D CAD design is mainly required to build a programming language (G code) for guiding movement and operation of CNC machine tools . Even for projects that do not require CNC machining (such as vacuum casting), it is useful to have a 3D CAD file to estimate raw material consumption and part weight.

General precision parts drawings: structural views, material selection, dimensions, process requirements (including heat treatment, surface treatment) mechanical parts drawings with high precision requirements: in addition to the above, additional dimension tolerances, geometric tolerances, and fits may be required , Special process requirements, etc.

In SANS Machining, it is best to prepare 2D engineering drawings in .pdf format, and accept 3D CAD files in .stl, .igs or .step format.

2. Material

The material of the finished machined part is an important factor in determining the total cost. Many types of metals and plastics can be used to make rapid prototyping and production parts. They each have unique mechanical and physical characteristics that can help you achieve the performance you need. The material price is not determined by CNC machining company. There are many materials available for CNC manufacturing and rapid prototyping. In SANS, we provide various metal and plastic materials, including brass, copper, bronze, steel, stainless steel, aluminum, titanium, alloy, nylon, PVC, ABS, PC, PEEK, POM, etc.

The choice of material depends on its mechanical properties, characteristics, processing technology and purpose. Tell us the properties you want to use or the performance of the product, and then we can provide you with a more accurate quotation, and we can consider related processing using the material Cost, so as to make the quotation more accurate.

3. Quantity

Quantity or production volume is also essential. This will change the delivery time and total cost. As you know, rapid prototyping is suitable for the testing and development of individual parts. CNC machining is ideal for low/medium/high-volume production. Recording the number of parts required can make quotations and delivery times clearer. Different manufacturing processes are most suitable for different numbers of parts. Therefore, it is best to know the quantity very well at the beginning of the quotation process.

4. Product Appearance

The appearance of the part may not be specified in the CAD design, such as color, surface finish and other text. Clear information can be recorded in graphics and files, but it is best to contact the supplier for subjective details. In order to obtain the most accurate product, some technical tools can be used. If you want to change the appearance or obtain a specific appearance, different processes or operations will leave a different surface finish on the outside of the part, and put forward your requirements, including roughness, color tone, etc.

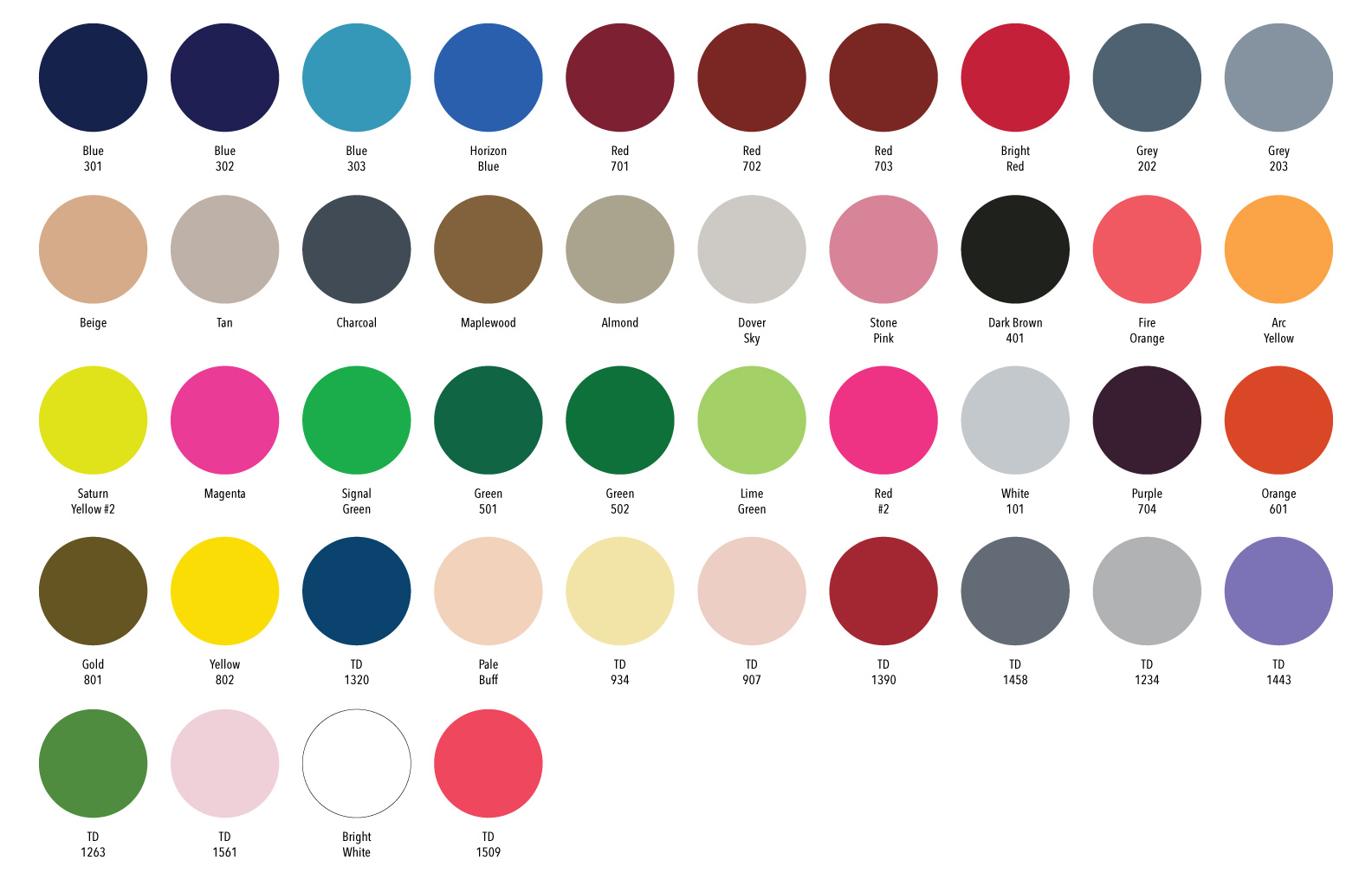

A) Color

The right color is very important to the success of product innovation. However, color may be subjective, so it is necessary to communicate this information to the supplier in a clear way.

B) Surface finish

No matter which manufacturing process is used, the final surface finish will remain on the part. However, this may not be the effect you want.

Therefore, whenever possible, it is best to specify the desired finish by using a gauge or template with reference to known surface finish standards. If flatness is important to your application, specify the Ra value (if known). If necessary, we can measure the texture and flatness of the samples you provide us.

5. Application

The target application or use of the machining part helps to select the best manufacturing process and raw materials. Product design is also based on the application area. For example, some applications require hard materials, while other products need to withstand extreme temperatures. In principle, the more detailed the information, the more advantageous it is to provide an accurate quotation, but not all information is needed. Prepare all the necessary details at one time to save time, not only to help us suggest the best materials and manufacturing processes, but also based on us Experience in producing thousands of products for various industries to provide insights into design improvements.

Related Post How To Choose The Right CNC Machining Service?

Usually, it takes 7 to 15 days for SANS to make customized cnc machined parts, and the fastest sample processing takes only one day. We aim to provide you with a detailed quotation within 12-48 hours. Send us your design or drawings immediately and get a quick free quote.