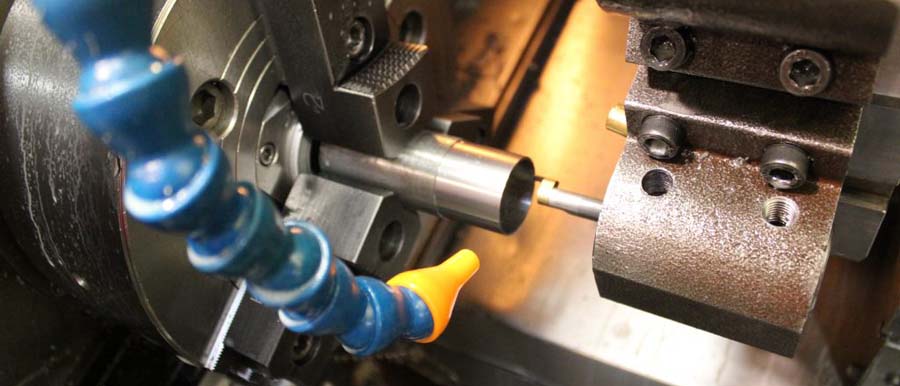

CNC turning is a machining process that relies on computers to produce accurate representations of digital blueprints. In recent years, the rapid development of CNC technology uses reliable parts, products and tools made of metal, plastic and even wood more easily than ever.

Turning is an act of using a lathe, which involves the use of cutting tools to remove material from larger workpieces. Now, with the help of CNC console, manual intervention in the turning process can be eliminated. It provides the industry with a fast and reliable tool that can precisely machine custom parts through CNC turning, thereby removing unnecessary material to form the desired shape. (Related Post: What Is CNC Turning? All About CNC Turning)

CNC turning has many advantages, let’s talk about the specific advantages of it.

Accuracy:

For many companies, the accuracy of CNC turning is one of their most competitive advantages. By incorporating CAD or CAM files into the process, the machine can perform rigorous measurements and eliminate the waste of natural human error. Using advanced machines, experts can provide extremely high accuracy, whether it is to produce prototypes or complete the entire production process. Especially when accuracy is critical, a small defect or a slight deviation from the tolerance is enough to cause serious damage. Since the machine used is programmed, every cut is perfect. In other words, the last component completed in the production run is the same as the first component.

Flexibility:

Flexibility is another benefit of precision turning services. They have multiple size functions to meet the flexibility of your various applications. Since the tasks performed by this machine are programmed, the change is relatively simple. By accessing the keyboard, the operator of the machine can complete a component for your company and then make the appropriate programming changes to produce something completely different. Therefore, you can rely on the same manufacturing company or precision CNC machining service provider to provide a large number of unique parts.

Repeatability:

By producing batches of unparalleled accuracy, CNC turning can provide excellent repeatability. In this way, your business can maximize output and reduce losses, which allows you to freely invest capital elsewhere.

Safety

The fact is that the operators who supervise the lathe must receive extensive training. After all, an environment with tools and machinery may pose a risk of personal injury or even more serious. To ensure 100% safety, the manufacturing company you choose will follow strict rules and regulations. The turning machine is automatic, which means that the operator is present but not on the machine, which can reduce labor intensity. At the same time, the lathe body adopts a fully enclosed or semi-enclosed protective device to prevent flying debris from the processed product and reduce the damage to the staff.

Faster Results

When using CNC lathes to perform tasks indicated by programming, there is less risk of errors. Therefore, this machine can complete production faster without affecting the quality of the finished product. In the end, you can finally get the parts or components needed by the industry faster than other solutions.

Since 2006, SANS Machining has been the most trusted provider of CNC machining in China. We are proud to provide each and every one of our clients with high-quality CNC machining services that meet their respective needs. Our talented technicians deliver fast, safe and accurate renderings of your original designs. Contacting us today to discuss your CNC machining needs.

How interesting that you talk about how CNC turning is so accurate and helps companies be competitive. I am starting a new industrial business this year and getting my equipment ready. I will find a reputable CNC lathe machine shop to help locally.