The surface hardening process is very important for our products in the entire industry, such as machinery, electronics, medical equipment, aerospace, and oil and gas. We produce many products and ultimately perform various tasks. Many applications mainly require high hardness or strength on the surface, and complex service stress usually requires not only a hard wear-resistant surface, but also core strength and toughness to withstand impact stress.

Two General Processes For Key Characteristics

In order to obtain these different characteristics, two general methods are used:

1) Change the chemical composition of the surface before or after quenching and tempering. The processes used include carburizing, nitriding, cyanidation and carbonitriding.

2) Only the surface layer is hardened through the heating and quenching process. The most common methods used for surface hardening are flame hardening and induction hardening.

The following is an in-depth analysis of surface hardening treatment

Carburizing Process

By heating the part in a carbonaceous medium, the carbon is diffused to the surface of the part to a controlled depth. The resulting carburizing depth (usually called the carburizing depth) depends on the carbon potential of the medium used and the time and temperature of the carburizing treatment. The most suitable steel for carburizing to increase toughness is steel with sufficiently low carbon content (usually less than 0.3%). The carburizing temperature range is 1550 to 1750°F (843 to 954°C), and the temperature and time are adjusted to obtain various surface depths. The choice of steel, hardenability and quenching type depend on the section size, required core hardness and service requirements.

The three most commonly used carburizing technologies

Liquid carburizing

Heat steel in molten barium cyanide or sodium cyanide. In addition to carbon, the case also absorbs some nitrogen, thus increasing the surface hardness.

Pack carburizing

This is done by sealing the solid carbon material and steel in an airtight container. Then heating.

Gas carburizing

This process involves heating steel in a gas containing a specific carbon content. When used, the carbon content can be strictly controlled.

Using any of these methods, it is possible to quench the part without reheating after the carburizing cycle, or to air-cool it and then reheat it to the austenitizing temperature before quenching.

The depth of the cabinet can be changed to suit the load conditions in use. However, maintenance characteristics often require that only selected areas of the part must be surface hardened. Covering the areas not to be cased, with copper plating or a layer of commercial paste, allows the carbon to penetrate only the exposed areas. Another method is to carburize the entire part and then process it by machining before hardening. Remove the shell in the selected area.

Nitriding Process

We perform this process by heating steel parts in the temperature range of 900 degrees Fahrenheit to 1150 degrees Fahrenheit in ammonia and decomposed ammonia. The formation of nitride enables the formation of a thin and hard shell. In order for this process to be successful, there must be elements with strong nitride forming capabilities in the steel. These elements include chromium molybdenum and special non-standard grades of steel containing aluminum. In addition, the main advantage of this process is that we can perform quenching, tempering and machining before nitriding. This is because only a small amount of deformation occurs during the nitriding process.

Cyanation Process

This process requires heating the parts in the dissolved sodium cyanide bath to a temperature slightly beyond the transformation range, and further quenching them to obtain thin hardness.

Carbonitriding

This process is similar to cyanidation. The difference is that the absorption of carbon and nitrogen is done by heating the parts in a gaseous atmosphere containing hydrocarbons and ammonia. For the parts to be quenched, the temperature used is 1425-1625°F (774 to 885°C), and if liquid quenching is not required, the temperature of 12000-1450°F (649 to 788°C) can be used Lower temperature.

Flame Hardening

The process involves rapid heating by exposing steel parts directly to a naked flame of high temperature gas. We heat the surface to a temperature above the transformation range and then subject it to a certain degree of cooling to completely harden it. The carbon content of our flame-hardened steel is between 0.30-0.60%. We spray quenching agent on the surface a short distance from the heating flame. Requires immediate tempering, and can be performed in a conventional furnace or through a flame tempering process depending on the size and cost of the part.

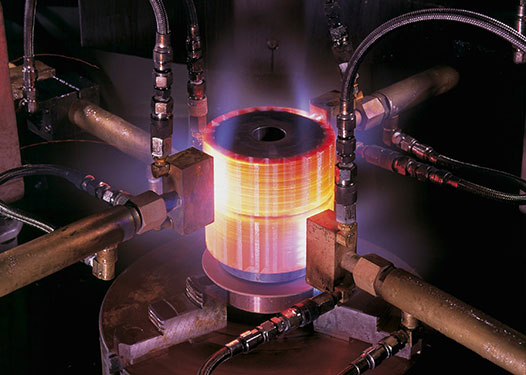

Induction Hardening

This process is somewhat similar to the flame hardening process, the main difference is that the high-frequency current surrounds the steel part to be hardened. Therefore, the depth of heating depends on the frequency, the thermal conductivity of the surface and the extent to which the surface is heated. We quench the parts by spraying water at appropriate intervals. Therefore, in some cases, we oil-quench parts by immersing them in an oil bath after reaching a certain temperature.

If you have machined parts need to do harden treatment, you can send the drawings to us and we can provide machined parts manufacturing and harden treatment as well.