In the past, designers needed to use simple tools such as paper and pencil to draw part drawings. With the advent and application of CAD software, it changed the design and production methods of the manufacturing industry, and soon entered the CNC machining process. CAD files are usually used for mechanical design and manufacturing, and it makes drawing more automated and accurate. Using CAD files, you can check out every detail of a part, even including internal features, and it can zoom in on the 3D model and rotate on any axis to better understand the parts. In addition, CAD makes it possible to simulate the movement of the workpiece through the CNC manufacturing process. (Related Post How To Prepare Your CAD Drawings For Machining Manufacturing)

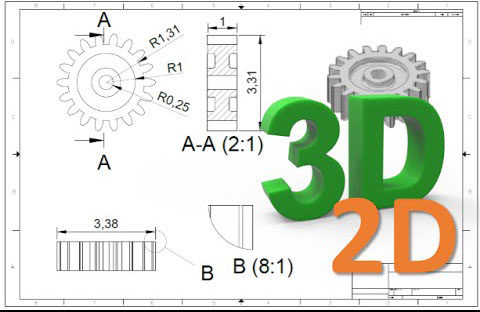

Most manufacturers have adopted 3D CAD, if you try to choose a better option between 2D and 3D CAD, and see the difference between 2D and 3D CAD drawings, we will also show the advantages of 3D CAD compared to 2D, Help you find the ideal solution.

Difference Between 2D and 3D CAD Drawing

1. Definition

2D CAD is two-dimensional computer-aided design, 3D CAD is three-dimensional computer-aided design.

2. Expression

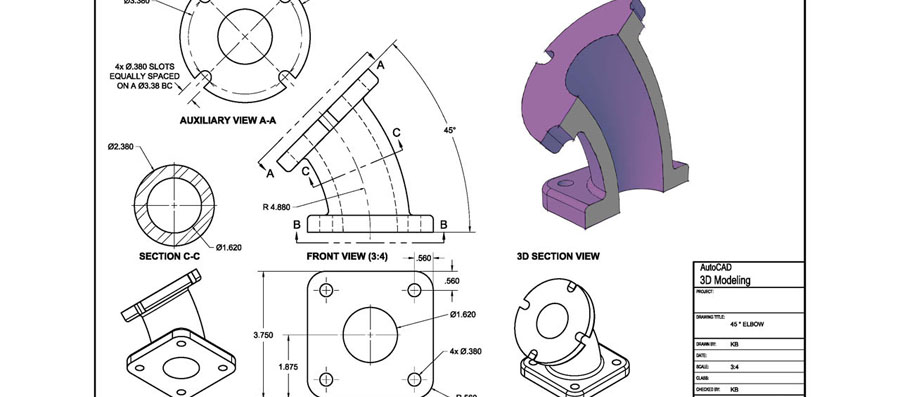

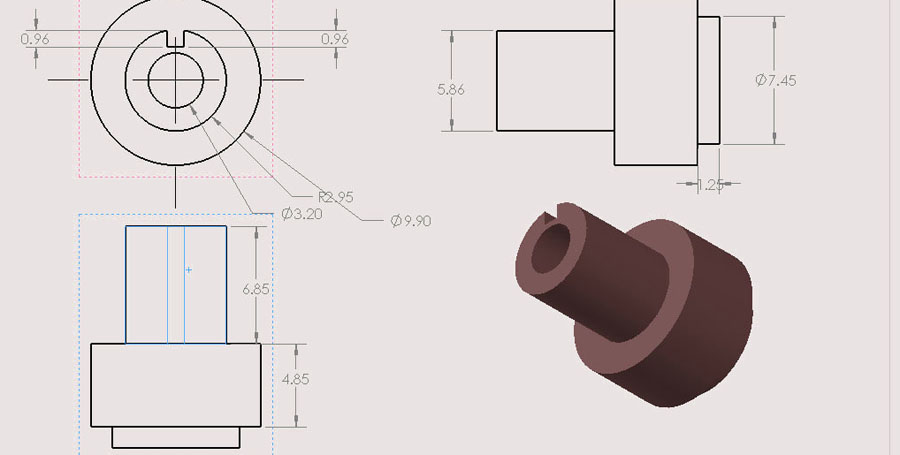

2D is to display length and height information on a flat surface without depth. Although 3D is defined as 3D drawings or models, they describe objects in terms of height, width, and depth.

3. Geometry

2D CAD engineering drawings are related to rectangles, squares, triangles, polygons, etc., while 3D engineering drawings include cylinders, cubes, spheres, pyramids, prisms, etc.

4. Measurement/Unit

2D engineering drawings are usually measured in square units (such as cm²), while 3D measurements are measured in cubic units cm³ and quarts liters.

5. Elements

In 2D CAD systems, product and engineering design drawings are usually regarded as a collection of geometric elements (such as points, lines, circles, arcs, etc.) that depend on the geometric model. The core of the 3D CAD system is the 3D model of the product, which represents the actual shape of the product on the computer. The model contains various information about the points, lines, surfaces and entities of the product geometry.

6. Presentation

Since 2D CAD engineering drawings are flat, designers must understand the appearance of the final product, which may be difficult for people who do not have a technical background. Using the 3D CAD model, we can see the final product, but most people can understand the design. When using 3D models to demonstrate to consumers and workers, it is easier to show and explain products.

The Main Benefits Of Going From 2D to 3D

Due to the development of 3D design, digital manufacturing has undergone tremendous changes. The use of 3D CAD technology has many advantages, including a richer design environment, a lower error margin, and a faster manufacturing route. After all, great design is about optimizing and finding the easiest and fastest way from innovative ideas to finished products.

Generally, in terms of mechanical design, compared with 2D CAD, the advantages of 3D CAD technology and software are as follows:

Improve Design Quality

With the support of 3D CAD technology, modern machinery production uses advanced design methods to improve the design level and ensure product quality, including optimization, product virtual design, finite element stress analysis, motion simulation, etc. Integration with information technology. In addition, CAD and CIMS are also used to organize production, which promotes the new development of mechanical product design.

Improve The Productivity Of Designers

3D CAD modeling helps designers visualize mechanical components in 3D at the initial stage and make any changes immediately when needed. This can improve the designer’s productivity because he does not have to revisit the design later

Easy To Record

Traditional drawing methods include manual recording of various aspects of mechanical parts, which is a tedious process and requires high accuracy. 3D CAD modeling is pre-installed with flexible documentation options, such as recording product geometry and size, material specifications, bill of materials, etc., thus simplifying the entire documentation process of component design.

Compatible With International Standards

The use of 3D CAD design ensures that the design is compatible with international standards. CAD supports BSI, ANSI, DIN, CSN, GB, ISO and GOST drawing platforms. Compliance with industry standards improves internal communication and leads to better output

Automatic Redraw Design

Redrawing hidden parts of components is a troublesome task for designers who use traditional drawing techniques. 3D CAD automatically redraws the lines and dashed lines of parts hidden from other mechanical parts designed. If there are any changes to the design, 3D CAD will automatically redraw the lines and dashed lines to eliminate any chance of error

Reduce Design Time

The traditional CAD drawing software and the existing two-dimensional drawing software cannot realize the parametric design. However, in the parameter and variable design process of 3D CAD, the parts can be changed according to the change of the structure size to achieve the appropriate effect. Similarly, when the size and shape of parts change, other related structures will also change. In this way, 3D CAD technology can help designers reduce a lot of workload, reduce working time and increase work efficiency by 3-5 times.

Provide Customers With Better Visualization

CAD software enables 3D design to display the structural features of components vividly and intuitively. When designing parts, designers can use 3D entities, or even 3D entities with very complex constraints, to implement simulation assembly and simulation operations in the design stage, so that the design is closer to the actual process. You can even animate the components and observe the working conditions. Visual graphics can help customers better understand the characteristics and attributes of components.

Saving Of Data And Drawings

Designs created on CAD can be easily saved for future reference. Some standard components do not need to be redesigned, which saves a lot of time for future design creation

Save Costs

3D CAD comes with many standard design components, freeing designers from the trouble of redesigning from scratch. This saves critical time and money. In addition, licensed modeling software is very expensive, so outsourcing 3D CAD modeling is the first choice because it helps to further save costs.

Facilitate CAD/CAM Integration

In traditional design, CNC machining is a drawing based on CAD design, so it is inevitable that there are two sets of the same part data in CAD and CAM, which can easily cause management confusion. Since 3D design can realize the integration of CAD/CAM, 3D CAD technology supports the entire product process from design to manufacturing. Through information integration and information flow automation, CAM can directly obtain CAD information for processing, thereby ensuring that the product obtained through processing is completely consistent with the design.

(Related Post: 6 Techniques For Importing CAD Drawings)