When cutting the workpiece, it is easy to be scrapped if you don’t pay attention to it. From the perspective of more than ten years of processing experience, SANS Machining summarizes the problem of “how to reduce the scrap rate in the machining process” from the following aspects.

1 Confirm Drawing Requirements

For mechanical products or parts, all our processing and production are based on drawings. This is the best and the best production data. It is unrealistic to talk about processing without drawing, so we need to look at the following aspects To ensure the correctness of the drawings.

A. Confirm That The Drawings Used Are The Latest

Many may not understand this problem very well. In fact, the drawings circulating in the workshop, especially the drawings in the hands of the operators, are very likely not the latest version, because the design and improvement of the part drawings is a process of continuous correction, so in In the product sales process, many parts still involve a large number of or have modifications, and from the modification of the R&D design engineer to the use of the workshop operator, this is a relatively long operation process, and the replacement of many drawings may be fundamental It is not timely, or even ignored at all, especially for many companies with non-standard management systems and poor implementation. Some drawings have been revised several versions in the design and research department, but the original version is still used in the workshop. Therefore, the same problem will continue to appear. If there is no special person to straighten out this matter, it is difficult to rely on the current system to remedy it. Therefore, as a machining staff, especially a process engineer at the machining site,-must To ensure that the version of the part drawing is updated to the maximum extent, confirm that the drawing version currently in use is the final part drawing version.

B. Confirm Various Processing Requirements In The Drawings

For example, dimensional requirements, behavioral tolerance requirements, roughness requirements, heat treatment requirements, etc., these information are very clear on the drawings. Of course, in view of the design ability of the design engineer, maybe these requirements are also missing, so you need to be experienced at this time. The mechanical process engineer of the company will check it. For example, according to the product drawings, assembly and use conditions, think about the product drawings to a certain extent, and make up the parts that the design engineers have missed. This is actually a process of continuous product improvement.

C. Confirm The Matching Of Drawings And Parts

This question seems a bit funny. Many people may wonder whether it can be processed with the wrong drawing. In fact, such a situation does exist in the real production site, especially when many parts have similar designs or symmetrical layouts. The wrong drawing was used for processing, because the blanks of the parts are the same. They were originally two drawings, but many people made one, and different parts were processed into two parts. This is very realistic. cost.

2. Confirm The Process Content

The process flow of parts is an important basis for the execution steps of our mechanical machining, and it is also an important guarantee for the quality of parts machining. In fact, the professional core capabilities of many mechanical process engineers are also reflected in this place, how to be correct, reasonable, low-cost, and high Efficient, high-quality design of the machining process of a part is the highest embodiment of the professional ability of an excellent process engineer. Therefore, in the machining of parts, we must fully respect the process flow of the part and strictly implement the process flow of the part.

However, many operators like to change this established process flow, because the operators in the process only have a single-pass vision and ability, and it is difficult for them to plan the processing of the entire part from the overall processing of a part, so in There are many defects in the selection of machining datum planes, the reservation of machining allowances, the adjustment of machining parameters, and the selection of machining tools. Such processing is difficult to guarantee the machining quality of the parts.

A qualified part machining technology not only needs to consider the processing equipment of the part, but also the processing method of the part, processing tools, processing parameters, clamping fixtures, cooling and lubrication, machining allowance, processing steps and sequence, and the selection of reference planes. Inspection methods and the design of tools or tooling, etc. all require in-depth consideration, which to a large extent determines the cost, quality and efficiency of parts machining.

3.Ensure Equipment Capabilities

The ability of processing equipment, in fact, the processing quality of a mechanical part, to a large extent, comes from the processing accuracy of the processing equipment, especially the processing of some high-precision parts, which is beyond the reach of manpower and can only be guaranteed by the equipment. For example, when the machining accuracy of the parts reaches the level of 0.001mm, which is the so-called μ level, there is no way for manpower at this time.

In addition to the requirements of machining accuracy, we also need to evaluate the requirements of the processing range and capabilities of the processing equipment. For example, if you are also processing a plane, whether you use a grinder or a milling machine, whether you use a wire cutting or a planer, this is very big The degree of difference, even the process flow and processing cost are completely different-of course, the processing quality obtained also has a very essential difference, these things require a clear understanding of the processing personnel.

If you are operating a milling machine that is only suitable for rough machining, and the process requires you to make a high-precision part, this is impossible from the equipment. The capacity of the equipment has determined the upper limit of the quality of the part. At this time If you do it hard, the scrap rate of your parts must be very high. This is not a problem of your ability, but a mistake in the choice of equipment.

At the same time, we also need to consider the processing stroke of the equipment. The feed axis of many equipment has stroke restrictions. The processing size of your parts must be within the maximum stroke range of the equipment. If it exceeds this stroke, it means There will be problems in the processing of parts. At least one clamping process cannot be completed. At this time, there may be a sacrifice in processing quality and processing efficiency, and the same rejection rate will also increase.

4. Effective Inspection methods

A. Selection Of Inspection Tools

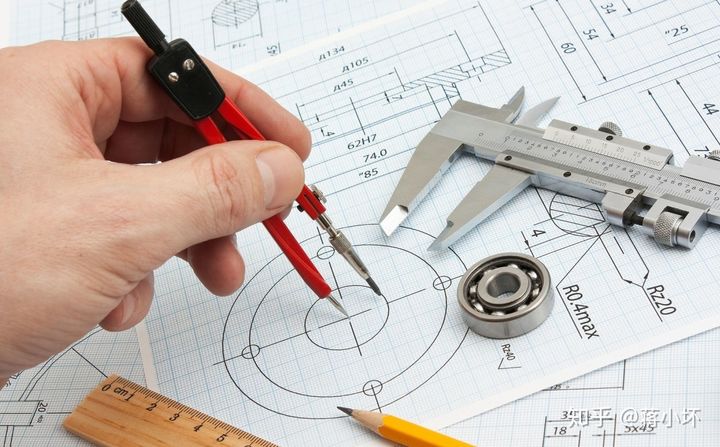

For the machining site, there are various parts quality inspection tools, such as dial gauges, micrometers, calipers, steel rulers, height gauges and other conventional inspection tools. There are also some three-coordinate measuring instruments, hardness testers and so on used in laboratories.

B. Selection Of Testing Fixture

Many parts, especially complex machined parts, need to be tested with corresponding test fixtures to assist in the measurement, especially when the test tools are limited, the test tooling becomes particularly important, for example, if you are using traditional To measure the error of the hole distance, you need to make a special test rod to assist, otherwise there is no way to achieve it, and you can also use three coordinates to measure.

C. Time Node Selection For Inspection

In fact, the processing of a part is a very complicated process, and the same quality inspection process is also correspondingly complicated. We can roughly divide the inspection time nodes of the parts into three types.

(1) Real-time inspection of parts

The advantage is that the quality of the parts can be controlled to the utmost extent and the scrap rate of the parts can be reduced. This is a kind of “on the fly” inspection, so we can correct our processing deviations in real time during the processing process to ensure the processing quality of the parts.

(2) Online inspection of parts

This situation is suitable for automatic production lines. An automatic production line is usually a fully automated processing mode with multiple stations connected in series. However, whether the processing quality of each station is really qualified is often an unknown number because of these stations. It has been connected in series. It is difficult for our labor to intervene in the quality inspection of the processed parts in time. Therefore, at this time, we need to have an online measuring device to monitor the quality of the processed parts. If unqualified parts are found, they can be removed in time. Only qualified parts can be transferred to the next process, which is also an indispensable part of the automated production line.

(3) Final Inspection

This kind of inspection includes both manual inspection and fully automated inspection. In fact, many companies are now introducing fully automated inspection, because this inspection method effectively shields the influence of artificial technology, attitudes and emotions, and can reflect the parts more realistically. At the same time, it has better control on the improvement of inspection efficiency and the reduction of inspection cost.

Through different inspection methods and means, it is also a very important means to improve the quality of parts processing and reduce the scrap rate.

5. Perfect Management System

The enterprise has a complete management system. In fact, the quality of mechanical processing needs to be matched by a complete quality management system to truly achieve quality control. Simply relying on the consciousness and quality of workers will always lag behind.

Therefore, a complete quality management system is a necessary control procedure, and it is also an internationally accepted product production rule, such as our ISO9000 quality certification, which is actually a very good quality management and control system. To obtain better product quality and lower rejection rate, the quality system is a very important guarantee.