The continuous emergence of new products puts forward higher requirements for the materials of the parts. Sometimes the required materials must meet the special requirements of high hardness, high wear resistance, high toughness, etc., resulting in a batch of difficult-to-process materials, and the machining technology is proposed higher requirements. Compared with high-quality carbon structural steel, stainless steel materials include Cr, Ni, Nb, Mo and other alloying elements. The increase of these alloying elements not only improves the corrosion resistance of steel, but also has a certain impact on the machining performance of stainless steel.

This article takes stainless steel and other difficult-to-machine materials as the object, combines the actual problems encountered in processing, analyzes the processing difficulties of stainless steel, and proposes practical and effective solutions.

This article combines the actual problems encountered in machining, analyzes the difficulties of stainless steel machining, and proposes practical and effective solutions.

Analysis of Difficulties in Stainless Steel Cutting

In actual machining, cutting stainless steel is often accompanied by the occurrence of knife breakage and sticking. Due to the large plastic deformation of stainless steel during cutting, the chips produced are not easy to break and easy to bond, resulting in serious work hardening during the cutting process. Each pass will produce a hardened layer for the next cutting. After layers of accumulation, the stainless steel is in the cutting process. As the hardness in the medium becomes larger and larger, the required cutting force also increases.

The production of the work hardening layer and the increase of cutting force will inevitably lead to the increase of friction between the tool and the workpiece, and the cutting temperature will also increase.

In addition, the thermal conductivity of stainless steel is small, the heat dissipation conditions are poor, and a large amount of cutting heat is concentrated between the tool and the workpiece, which deteriorates the machined surface and seriously affects the quality of the machined surface. Moreover, the increase in cutting temperature will aggravate tool wear, cause crescent craters on the rake face of the tool, and gaps on the cutting edge, which will affect the surface quality of the workpiece, reduce work efficiency, and increase production costs.

Ways to improve the quality of stainless steel machining

It can be seen from the above that the machining of stainless steel is more difficult, and it is easy to produce a “hardened layer” during cutting, which is easy to break the tool, the generated chips are not easy to break, resulting in sticking to the tool, which will aggravate the wear of the tool. For these cutting characteristics of stainless steel, combined with production In fact, we started from three aspects of tool materials, cutting parameters and cooling methods to find ways to improve the quality of stainless steel machining.

3.1 Selection of tool materials

Choosing the right tool is the basis for machining high-quality parts. The tool is too bad, and no qualified parts can be processed; if a good tool is selected, although it can meet the surface quality requirements of the part, it is easy to cause waste and increase the production cost. Combined with the characteristics of poor heat dissipation conditions, work hardened layers, and easy sticking of the knife during stainless steel cutting, the selected tool material should meet the characteristics of good heat resistance, high wear resistance, and low affinity with stainless steel.

3.1.1 High Speed Steel

High-speed steel is a high-alloy tool steel with W, Mo, Cr, V, Go and other elements added. It has good process performance, good strength and toughness, and strong shock and vibration resistance. In the case of high heat generated by high-speed cutting (about 500 °C), it can still maintain high hardness (HRC is still above 60). High-speed steel has good red hardness and is suitable for making milling cutters, brambles and other milling tools, which can meet the requirements of stainless steel cutting. Cutting environment such as hardened layer and poor heat dissipation.

W18Cr4V is the most typical high-speed steel tool. Since its birth in 1906, it has been widely manufactured into various tools to meet the needs of cutting. But with the continuous improvement of the mechanical properties of various processed materials, W18Cr4V tools can no longer meet the processing requirements of difficult-to-process materials. High-performance cobalt high-speed steel should be born from time to time. Compared with ordinary high-speed steel, cobalt high-speed steel has better wear resistance, red hardness and reliability in use. It is suitable for high removal rate processing and interrupted cutting processing. Commonly used grades such as W12Cr4V5Co5.

3.1.2 Hard alloy steel

Cemented carbide is a powder metallurgy made of high-hardness refractory metal carbide (WC, TiC) micron powder as the main component, cobalt, nickel, and molybdenum as the binder, and sintered in a vacuum furnace or a hydrogen reduction furnace. Products. Cemented carbide has good strength and toughness, heat resistance, wear resistance, corrosion resistance, high hardness, etc.-series of excellent properties. It also remains basically unchanged at a temperature of 500°C, and still has a high hardness at 1000°C, which is suitable for the cutting of difficult-to-machine materials such as stainless steel and heat-resistant steel. Common cemented carbides are mainly divided into three categories: YG type (tungsten-cobalt cemented carbide), YT type (tungsten titanium cobalt type), YW type (tungsten titanium tantalum (niobium) type), the composition of these three alloys is different, The uses are also very different. Among them, YG hardened uranium has good toughness and thermal conductivity. A larger rake angle can be selected, which is suitable for cutting stainless steel.

3.2 Selection of geometric parameters for cutting stainless steel tools

1) Rake angle yo:

In combination with the characteristics of stainless steel’s high strength, good toughness, and chips that are not easily cut off during cutting, a larger rake angle should be selected on the premise of ensuring that the knife has sufficient strength, which can reduce the processing object Plastic deformation can also reduce the cutting temperature and cutting force, while reducing the production of hardened layers.

2) Relief angle ao:

Increasing the relief angle will reduce the friction between the machined surface and the flank surface, but the heat dissipation capacity and strength of the cutting edge will also decrease. The size of the relief angle depends on the cutting thickness. When the cutting thickness is large, a smaller relief angle should be selected.

- The main deflection angle kr, the secondary deflection angle k’r:

The decrease of the main deflection angle kr can increase the working length of the cutting edge, which is beneficial to heat dissipation, but it will increase the radial force during cutting, which is prone to vibration. The value of kr is often taken It is 50° ~ 90°. If the rigidity of the machine tool is insufficient, it can be increased appropriately. The secondary declination angle is often taken as k’r=9°~15.

4) Blade inclination λs:

In order to increase the strength of the tool tip, the blade inclination angle is generally taken as λs=7°~_ -3°.

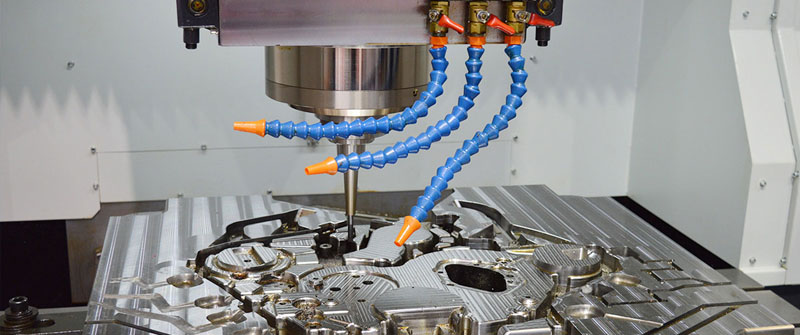

3.3 Selection of cutting fluid and cooling method

The machinability of stainless steel is poor, and there are higher requirements for the cooling, lubrication, penetration and cleaning performance of the cutting fluid. There are several types of commonly used cutting fluids:

1) Emulsion:

a more common cooling method, with better cooling, cleaning, and lubricating properties, and is often used for stainless steel rough cars.

2) Vulcanized oil:

high melting point sulfide can be formed on the metal surface during cutting, and it is not easy to be destroyed at high temperature, has good lubricating effect, and has a certain cooling effect,-generally used for drilling, reaming and tapping .

3) Mineral oil such as engine oil and spindle oil:

It has good lubrication performance, but poor cooling and permeability, and is suitable for external precision turning.

During the cutting process, the cutting fluid nozzle should be aimed at the cutting area, or it is better to use high-pressure cooling, spray cooling and other cooling methods.

In summary, although stainless steel has poor machinability, serious work hardening, large cutting force, low thermal conductivity, easy sticking, easy to wear tools and other shortcomings, as long as you find a suitable processing method, use a suitable tool, cutting method and Cutting amount, choosing the right coolant, thinking diligently in the work, the problem of difficult-to-machine materials such as stainless steel is solved.