In order to improve the viability and competitiveness of precision machining enterprises, among many factors, the key is to rely on advanced technology. With the development of modern industry, more and more companies have begun to pay attention to craftsmanship. Craft documents are the foundation of precision machining enterprises, and their correctness is very important. As small as one symbol and one data in the process file, it is very important, such as the size requirements in the mechanical manufacturing technology file, the geometric tolerance requirements, the symbols and codes of the CNC machining program, etc. Especially for the processing of precision mechanical parts, the use of correctness process documents directly affects the processing quality and production safety of the product. Sometimes due to the negligence of the craftsman, even small mistakes, it may also lead to the scrapping of precision mechanical parts, causing certain economic losses to the enterprise.

In the process of precision machining, in order to effectively improve the performance of the product, it is necessary to ensure that most of the remaining parts have been removed when arranging the location of the heat treatment process. It not only ensures that the parts can be quenched and hardened, but also that there is a margin to meet the subsequent processing, so that the quality of the product can be better ensured. The heat treatment in the precision machining process can be roughly divided into preliminary heat treatment and heat treatment according to the purpose of application. The purpose of preliminary heat treatment is to improve mechanical properties, eliminate internal stress, and prepare for heat treatment. It includes annealing, normalizing, quenching and tempering, and aging treatment.

1. Preliminary Heat Treatment

The purpose of the preliminary heat treatment is to eliminate the internal stress generated during the blank manufacturing process, improve the cutting performance of metal materials, and prepare for the final heat treatment. The preliminary heat treatment includes quenching and tempering, annealing, normalizing, etc., which are generally arranged before and after rough machining. Arrangement before roughing can improve the cutting performance of the material. Arrangement after rough machining is beneficial to eliminate residual internal stress.

Process location for annealing and normalizing

It is generally arranged after the blank production and before the cutting process.

For precision parts, in order to eliminate the residual stress in the cutting process, stress relief annealing should also be arranged between the cutting process.

Process position of quenching and tempering

This kind of heat treatment can be used as the final treatment, and can also prepare the organization for the subsequent surface quenching or the overall quenching of easily deformable parts. It is generally arranged after rough machining and before finishing or semi-finishing.

2. Final Heat Treatment

The final heat treatment should generally be arranged after rough machining, semi-finishing, and before and after finishing. Heat treatment with large deformation, such as carburizing and quenching, quenching and tempering, etc., should be arranged before finishing, so as to correct the heat treatment during finishing. Deformed. Heat treatment with less deformation, such as nitriding, can be arranged after finishing. After this kind of heat treatment, the hardness of the parts is higher and should be as far back as possible. Generally, they are arranged after semi-finishing and before grinding.

The overall quenching and surface quenching process position arrangement is basically the same.

The deformation, oxidation, and decarburization of the quenched parts should be removed during grinding, so a grinding allowance should be reserved (for example, for quenched parts with a diameter of 200mm or less and a length of 1000mm, the grinding allowance is generally 0.35~0.75mm).

For surface hardened parts, in order to improve the mechanical properties of the core and obtain the surface quenched structure of the fine-grained martensite structure, it is often necessary to perform normalizing or quenching and tempering treatment first. Because the deformation of the surface hardened parts is small, the grinding allowance should also be smaller than that of the overall hardened parts.

For Example:

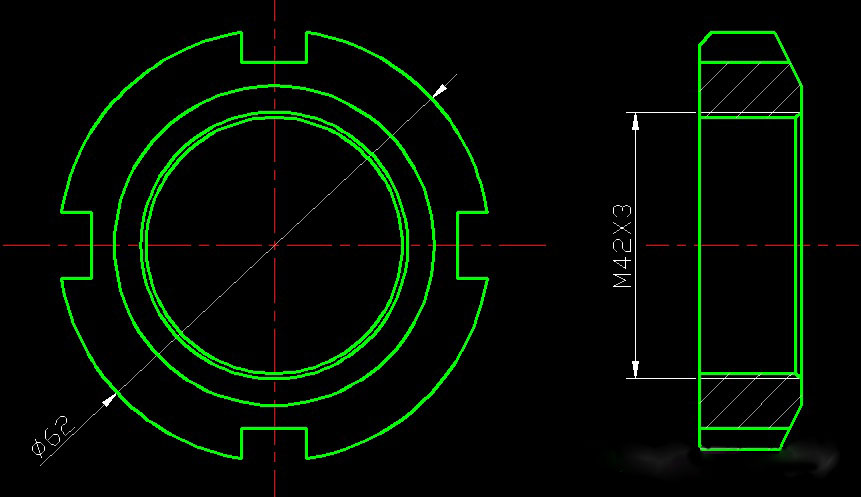

The above picture is a lock nut made of 45 steel, and the notch hardness is required to be HRC35~40. If the notch and internal thread are all processed and then quenched and tempered as a whole, although the hardness of the notch can meet the requirements, the internal thread is deformed and accuracy cannot be guaranteed; if it is cut after heat treatment, the hardness will be higher and the machinability will be poor. .

If the heat treatment method and processing sequence are changed into: quenching and tempering-processing notch-notch high-frequency quenching-processing internal thread, the technical requirements can be met and the deformation of the parts can be reduced.

3. Aging Treatment

The purpose of aging treatment is to eliminate internal stress and reduce workpiece deformation. Aging treatment is divided into three categories: natural aging, artificial aging and cold treatment. Aging treatment is generally arranged after rough machining and before finishing. For parts with higher precision requirements, an aging treatment can be arranged after semi-finishing. The ice-cold treatment is generally arranged after the tempering treatment or after finishing or at the end of the process.

4. Surface Treatment

For surface anti-corrosion or surface decoration, sometimes the surface needs to be coated or blued. This surface treatment is usually arranged at the end of the process.

The above is the relevant content of the precision machining and arranging the location of the heat treatment process, I hope it can be helpful to you.