Drilling is a material-removing or cutting process in which the tool uses a drill bit to cut a hole of circular cross-section in solid materials. We will introduce the drilling techniques from the use of coolant, chip control, feed and cutting speed control, and a rough introduction to the techniques for obtaining high-quality holes and the drilling techniques for different materials.

Use Of Coolant

The correct use of coolant is essential to obtain good drilling performance. It will directly affect the chip removal, tool life and the quality of the machined hole during machining.

1.How To Use Coolant

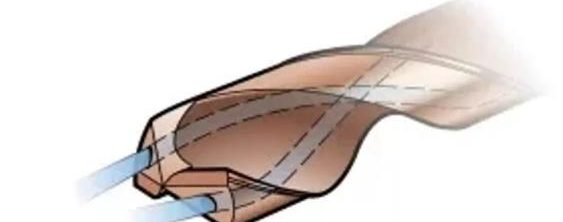

1) Inner cooling design

The internal cooling design is always the first choice to avoid chip blocking, especially when processing long chip materials and drilling deeper holes (greater than 3 times the hole diameter). For a horizontal drill bit, when the coolant flows out from the drill bit, there should be no undershoot of the cutting fluid over a length of at least 30 cm.

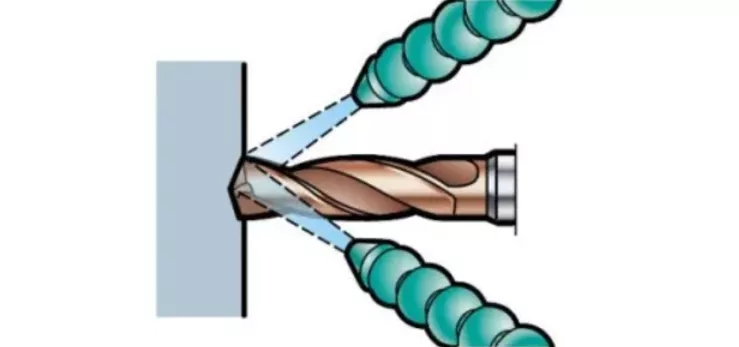

2) External Cooling Design

The use of external coolant can be used when the chip formation is good and the hole depth is shallow. In order to improve chip evacuation, there should be at least one coolant nozzle (or two nozzles if it is a non-rotating application) close to the tool axis.

3) Dry drilling techniques without using coolant

Dry drilling is generally not recommended.

- It can be used in applications with short chip materials and hole depth up to 3 times the diameter

- Suitable for horizontal machine tools

- It is recommended to reduce the cutting speed

- Tool life will be reduced

It is recommended not to use dry drilling for:

- Stainless steel material (ISO M and S)

- Interchangeable bit drill bit

4) High pressure cooling (HPC) (~70 bar)

The benefits of using high-pressure coolant are:

- Due to the enhanced cooling effect, the tool life is longer

- Improve the chip removal effect in the processing of long chip materials such as stainless steel, and may extend the tool life

- Better chip removal performance, so higher safety

- Provide sufficient flow according to the given pressure and hole size to maintain the coolant supply

2 Use skills of coolant

Be sure to use a soluble cutting oil (emulsion) containing EP (extreme pressure) additives. In order to ensure the best tool life, the oil content in the oil-water mixture should be between 5-12% (between 10-15% when processing stainless steel and superalloy materials). When increasing the oil content of the cutting fluid, be sure to check with an oil separator to ensure that the recommended oil content is not exceeded.

When conditions permit, internal coolant is always the first choice compared to external coolant.

The clean oil can improve the lubrication effect and bring benefits when drilling stainless steel applications. Be sure to use it together with EP additives. Both solid carbide drill bits and indexable insert drill bits can use clean oil and can achieve good results.

Compressed air, mist cutting fluid or MQL (minimal lubrication) may be a successful choice under stable conditions, especially when machining certain cast irons and aluminum alloys. As the temperature increase may have a negative impact on tool life, it is recommended to reduce the cutting speed.

Chip Control Skills

Chip forming and chip removal are key issues in drilling, depending on the material of the workpiece, the choice of drill/blade geometry, coolant pressure/capacity, and cutting parameters.

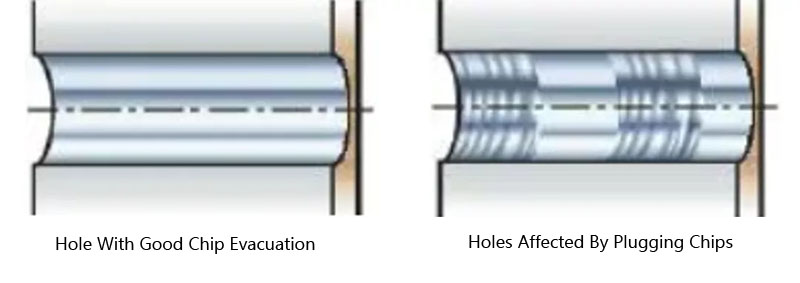

Blocking chips will cause the drill to move radially, which will affect hole quality, drill life and reliability, or cause the drill/blade to break.

When the chips can be smoothly discharged from the drill bit, chip shaping is acceptable. The best way to identify it is to listen during the drilling process. Continuous sound indicates good chip evacuation, and intermittent sound indicates chip clogging. Check the feed force or power monitor. If there is an abnormality, the cause may be clogged chips. Check the chips. If the chips are long and curved, but not curled, it means that the chips are clogged. Check the hole. After the chips are clogged, you will see a rough surface.

Tips to avoid Block chipping:

1) Ensure that the correct cutting parameters and drill/tool tip geometry are used

2) Check the chip shape-adjust the feed rate and speed

3) Check the cutting fluid flow and pressure

4) Check the cutting edge. When the entire chipbreaker is not working, the cutting edge damage/chip may cause long chips

5) Check whether the machinability is changed due to the new batch of workpieces-adjust the cutting parameters

Control of feed and cutting speed

(1) The influence of cutting speed Vc (m/min)

In addition to material hardness, cutting speed is also the main factor affecting tool life and power consumption.

1) Cutting speed is the most important factor in determining tool life

2) Cutting speed will affect power Pc (kW) and torque Mc (Nm)

3) Higher cutting speed will produce higher temperature and increase flank wear, especially at the peripheral tool tip

4) When processing some soft long chip materials (ie low carbon steel), higher cutting speed is conducive to chip formation

Cutting speed is too high:

- a) The flank wears too fast

- b) Plastic deformation

- c) Poor hole quality and poor hole diameter

Cutting speed is too low:

- a) Generate built-up tumor

- b) Poor chip removal

- c) Longer cutting time

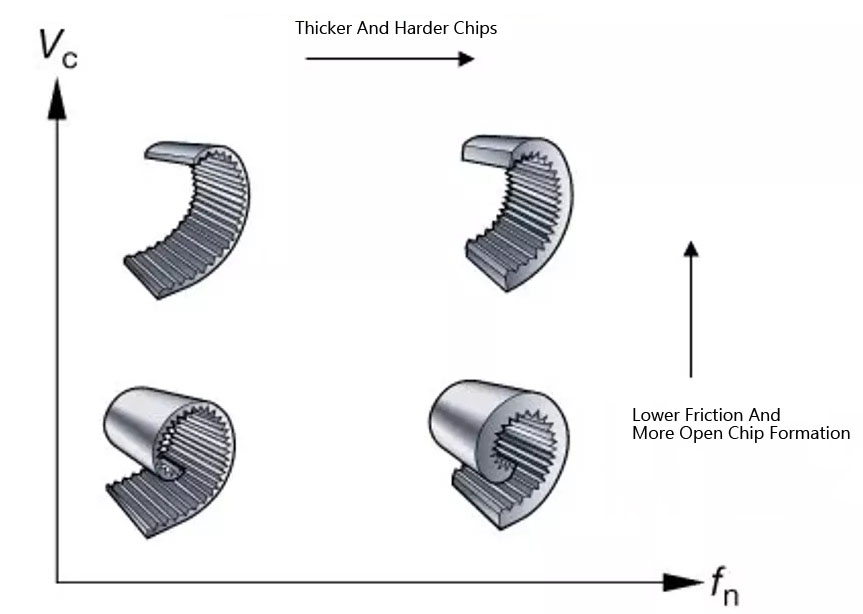

(2) The influence of feed fn (mm/r)

1) Affect chip formation, surface quality and hole quality

2) Influence power Pc (kW) and torque Mc (Nm)

3) High feed will affect the feed force Ff (N), which should be considered when the working condition is unstable

4) Affect mechanical stress and thermal stress

High feed rate:

- a) Hard chip breaking

- b) Short cutting time

- c) Tool wear is small but the risk of drill edge chipping increases

- d) The hole quality is reduced

Low feed rate:

- a) Longer and thinner chips

- b) Quality improvement

- c) Accelerated tool wear

- d) Longer cutting time

- e) When drilling thin parts with poor rigidity, the feed rate should be kept low

Tips for obtaining high-quality holes

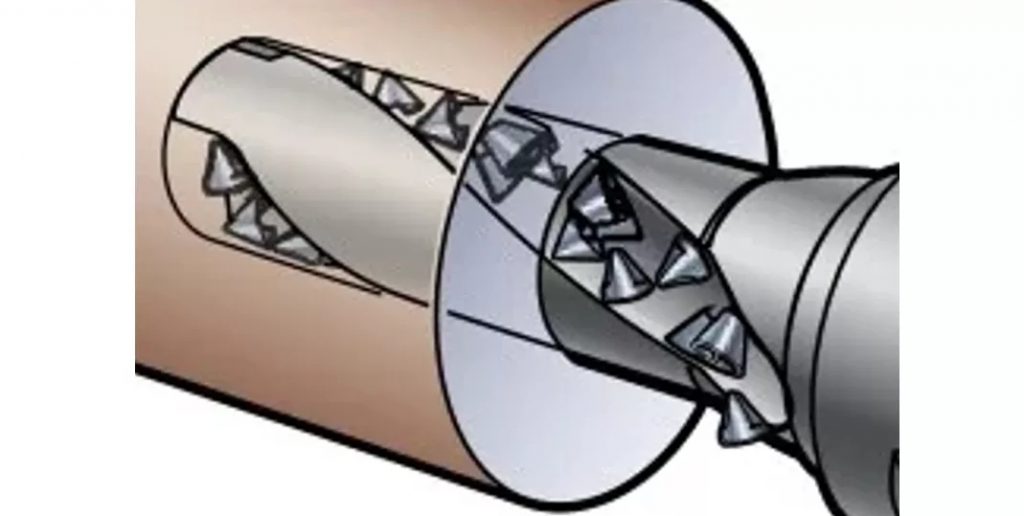

(1) Chip removal

Ensure that the chip removal performance meets the requirements. Chip clogging affects hole quality, reliability and tool life. The drill/insert geometry and cutting parameters are critical.

(2) Stability, tool clamping

Use the shortest possible drill bit. Use the refined rigid tool holder with the smallest runout. Ensure that the machine spindle is in good condition and precisely aligned. Ensure that the parts are fixed and stable. Apply the correct feed rate for irregular surfaces, inclined surfaces and cross holes.

(3) Tool life

Check the wear of the blade and preset the tool life management program. The most effective method is to use a feed force monitor to monitor drilling.

(4) Maintenance

Replace the blade compression screw regularly. Clean the knife holder before replacing the blade, making sure to use a torque wrench. Do not exceed the maximum amount of wear before regrinding the solid carbide drill.

Drilling Techniques For Different Materials

1. Low carbon steel drilling skills

For low carbon steels that are often used for welding parts, chip formation can be a problem. The lower the hardness, carbon content, and sulfur content of the steel, the longer the chips produced.

1) If the problem is related to chip forming, increase the cutting speed vc and reduce the feed fn (please note that when processing ordinary steel, the feed should be increased).

2) Use high pressure and internal coolant supply.

2. Drilling techniques for austenitic and duplex stainless steel

Austenitic, duplex and super duplex materials can cause problems related to chip formation and chip evacuation.

1) The correct geometry is very important, because it can make the chips form correctly and help them to be discharged. Generally speaking, it is best to use a sharp cutting edge. If the problem is related to chip forming, increasing the feed fn will make the chip more likely to break.

2) Inner cooling design, high pressure.

3 CGI (compact graphite cast iron) drilling skills

CGI usually does not require special attention. It produces larger chips than gray cast iron, but the chips are easy to break. The cutting force is higher and therefore affects tool life. Need to use super wear-resistant materials. There will be the same typical tool tip wear as all cast irons.

1) If the problem is related to chip forming, increase the cutting speed Vc and reduce the feed fn.

2) Inner cooling design.

4. Aluminum alloy drilling skills

Burr formation and chip evacuation can be a problem. It may also cause short tool life due to sticking.

1) To ensure the best chip formation, use low feed and high cutting speed.

2) To avoid short tool life, different coatings may need to be tested to minimize sticking. These coatings may include diamond coatings, or no coatings at all (depending on the substrate).

3) Use high-pressure emulsion or mist coolant.

5. Titanium alloy and high temperature alloy drilling skills

The work hardening of the hole surface affects the subsequent processes. It is difficult to obtain good chip removal performance.

1) When choosing a geometry for machining titanium alloys, it is best to have a sharp cutting edge. When machining nickel-based alloys, a robust geometry is essential. If there is a work hardening problem, try to increase the feed rate.

2) High pressure coolant up to 70 bar improves performance.

6. Hardened steel drilling skills

Obtain acceptable tool life.

1) Reduce the cutting speed to reduce heat. Adjust the feed rate to obtain acceptable and easy-to-eject chips.

2) High-concentration mixed emulsion.