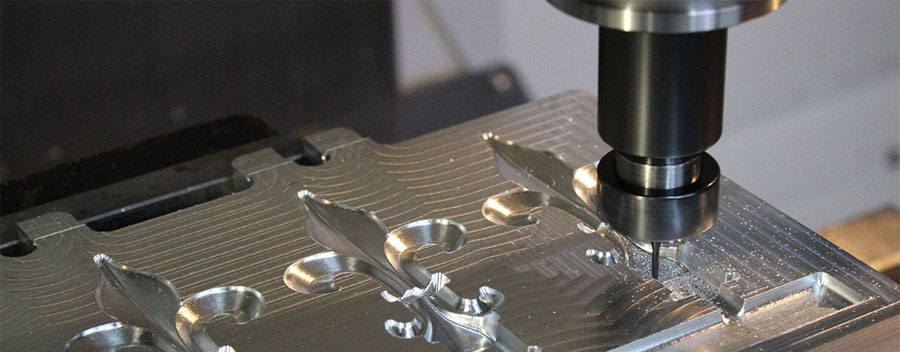

Face milling, shoulder milling, profiling milling, cavity milling, slot milling, turning milling, thread milling, plunge milling, ramp milling and arc interpolation milling can be completed on the machining center. In recent years, the application of machining centers has been increasing. And milling is the most common processing method for machining centers. When selecting the content of CNC milling, the advantages and key roles of CNC milling machines should be fully utilized. The following briefly introduces the problems that need to be paid attention to in the milling process.

1. The Choice Of Milling Direction

In the milling process, the workpiece can be fed along or relative to the direction of the tool rotation, which will affect the start and finish characteristics of the cutting. Regardless of the requirements of machine tools, fixtures and workpieces, down milling is the preferred method. However, if the tool is pushed into the workpiece, the feed rate will increase irregularly, which will cause the cutting thickness to be too large and cause the tool to collapse. In such applications, up-cut milling should be selected. In addition, when the machining allowance changes greatly, it is more advantageous to choose up-milling.

2. Tool Diameter And Position

The choice of milling cutter diameter is usually based on the width of the workpiece and the effective power of the machine tool. Especially when performing face milling, the milling width of the workpiece will directly determine the determination of the milling cutter diameter, because it helps to ensure good chip formation and proper cutting edge load. Ideally, the positioning of the milling cutter should always be slightly off-center, because the cut formed by each blade at this time is very small, and the entry and exit of the blade is conducive to chip formation and prevent impact load.

But if the tool is completely positioned to the center, when the cutting edge enters or exits the incision, the average radial force will continue to change in direction, the machine tool spindle will vibrate, and the blade may break, resulting in poor surface quality. . The position of the milling cutter relative to the workpiece, the cutting tool and the contact with the cutter teeth are all extremely important factors for the successful completion of the process.

3. Entry And Exit Conditions

(1) Every time a milling cutter blade enters the incision, the cutting edge may be affected by impact load. This depends on the chip cross section, workpiece material and chip type. For the milling process, it is extremely important that the type of initial and final contact between the cutting edge and the workpiece material is appropriate. In addition, accurate positioning of the tool is also important for the entry and exit of the cutting edge.

(2) The width of the workpiece is greater than or equal to the diameter of the milling cutter

In this case, the center line of the tool is completely outside the width of the workpiece, and the outermost tip of the tool will be strongly impacted when the blade cuts in. This means that the most sensitive parts of the tool are susceptible to the initial impact load. The blade will also leave the incision and only keep the tip contact, which means that the cutting force will be completely applied to the outermost end of the blade and will remain until the blade suddenly leaves the workpiece, this is the impact unloading force.

(3) The diameter of the milling cutter is slightly larger than the width of the workpiece

In this case, the center line of the tool and the edge of the workpiece are in the same straight line. When the chip thickness is at its maximum, the blade will leave the cut, and the impact load will be very high when the blade cuts in and cuts out.

4 The Advantages Of The Milling Process

(1) Compared with ordinary machining, the processing time can be shortened, and the production efficiency and the utilization rate of the machine tool can be improved.

(2) Small thermal deformation of the workpiece, high machining accuracy, good surface quality, wide range of processing technology, suitable for processing thin-walled, poorly rigid, and easily thermally deformed parts.

(3) The tool cooling of the high-speed machining machine tool adopts oil mist semi-dry cooling, using special high-speed cutting oil, and the minimum lubricating oil supply. A thin oil film is formed on the surface of the workpiece, which can greatly improve the surface quality of the workpiece compared with the traditional way of using coolant or air cooling.

5 The Selection Of High-Speed Cutting Oil

(1) When cutting copper, aluminum alloy and non-ferrous metals and light metals, the cutting force and cutting temperature are not high. You can choose special cutting oil for copper and aluminum alloy with a low proportion of anti-wear agents but good corrosion resistance.

(2) When cutting alloy steel, if the cutting volume is low and the surface roughness is small, such as broaching and thread cutting require cutting oil with excellent extreme pressure performance, extreme pressure cutting oil with sulfurized fatty acid ester as the main additive can be selected.

(3) When cast iron and bronze are brittle materials, chipping chips are often formed during cutting, which are easy to flow with the cutting oil and flow into the machine tool rails to cause damage to the parts. Use cutting oil with good cooling and cleaning performance and do a good job of filtering. .

(4) When cutting titanium alloys, the extreme pressure performance of the cutting oil is extremely demanding. In addition, it is necessary to conduct a comprehensive test on the fluidity and corrosion properties of the oil to prevent hydrogen embrittlement and built-up edge problems during the machining process.