In recent years, people’s requirements for metal precision machining parts have become higher and higher. While people are pursuing quality, they are also pursuing aesthetics. Therefore, the surface treatment of metal precision machined parts is indispensable.

No matter what material it is, it is inseparable from the processing process. It is a variety of surface treatment processes. For example, the surface treatment process of metal precision machined parts includes sandblasting, electroplating, PVD, spraying, anodizing, etc. Today we will introduce anodizing.

Anodizing is a surface treatment process. The last process of metal manufacturing is surface finishing, which is a reliable and relatively cheap method for the anodizing of precision machined metal parts. It is mainly applied to aluminum metal parts.

Anodization is an electrochemical conversion process that usually forms an oxide film on aluminum in an electrolyte (chemical solution). The aluminum part is the anode (hence the name “anodic oxidation”), and the current passes through them. The above-mentioned electrolyte (the most commonly used is sulfuric acid) between the cathode and the cathode is usually a flat aluminum strip. There are different types of anodizing, the most common are type I chromic acid anodizing, type II sulfuric acid anodizing and type III hard anodizing.

How It Is Done

Anodization is a highly controlled form of oxidation. In nature, oxidation will corrode ferrous metals. However, if used properly on non-ferrous metals, it will have the opposite effect. Aluminum is a common choice because of its light weight and corrosion resistance, but processing techniques for titanium, magnesium, zinc, and other iron-deficient metals do exist.

A common method of anodizing aluminum involves immersing the part in a sulfuric acid bath, which creates micropores (nanopores) on the aluminum surface. When an electric current is applied to the medium and the cathode is added, oxygen ions are released from the acid and combined with aluminum. This forms an oxide layer, and if necessary, color can be applied at this time. Finally, a sealant is used to seal the nanopores and any microcracks in the oxide layer.

Unlike electroplating or paint that only covers the surface, anodizing is part of the metal, so it will not flake, chip, or flake over time. Just like the black oxidation transformation process of steel alloy, it will not flake or flake, because oxidation is transformed from metal.

Benefit

Durability

As mentioned above, anodization changes the aluminum substrate at the molecular level. The anodized parts will not chip, peel or peel off, and have strong corrosion resistance and wear resistance.

Low Cost, High Value

The service life of anodized aluminum parts is longer than that of similar parts sprayed or electroplated, and the manufacturing cost is lower.

Environment Friendly

Unlike spraying and electroplating, anodizing does not generate hazardous waste or interfere with the recyclability of aluminum.

Easy To Maintain

The parts looked primitive at the time of production and have remained in this state for many years. Soap and water or mild detergents can remove dirt and restore the finish relatively easily.

Beautiful

The precision-processed parts are anodized to retain the metallic luster of the parts, the color is easy to repeat, and can be used for future production.

Improve Lubricity

For internal components, the porosity of the unsealed anodized surface can improve the adhesion and lubricity of the adhesive. However, this may expose them to contaminants, and unsealed or partially sealed components require special attention and consideration.

How To Improve The Yield Of Anodized Precision Machined Parts?

- Cleaning: It needs to be cleaned before anodizing to reduce scratches and bad stains after anodizing.

- Sandblasting: Sandblasting one by one to avoid incompleteness. Place them one by one after sandblasting and do not stack them.

- Oxidation: Control the time to control the brightness and matt of the precision processed parts to ensure the same color.

- Dyeing: When dyeing, swing the hanger at a constant speed to make dyeing even and control dyeing time.

- Finish: After finishing, you need to take out the product carefully to avoid being scratched by the hanger.

Conclusion

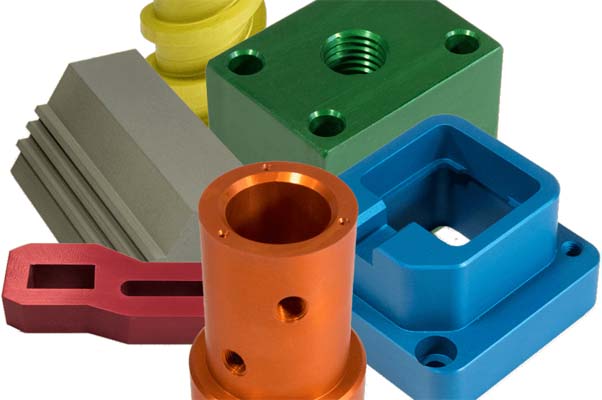

With more than 11 years of experience in manufacturing precision parts, we believe that anodizing is a reliable, economical and proven aluminum part finishing process. We use a network of qualified partners to provide anodizing treatment for our customer projects. Available colors include transparent, yellow, green, red and black or other colors.

As an ISO9001:2015 certified supplier, all parts have undergone strict inspection and quality assurance. According to the specifications required by the project, your anodized parts will remain in the best condition for many years.