In the machining of precision parts, after many parts are processed by precision equipment, there are always some “unsatisfactory” places. Obviously, they are the best processing masters and the best processing equipment. It was confirmed on the machine that everything was so perfect, but when the machine was taken off and sent to the quality control room or the next process, it was found that the size had changed quietly, and the original perfect product became a waste product.

In fact, this is the problem of process arrangement. We only considered the above process of machining, but failed to consider the characteristics of the material itself, resulting in changes in the internal structure of the material after the parts are processed, resulting in processing deformations, resulting in poor dimensions.

But how to avoid this undesirable occurrence? A very important process must be used, that is, the “stress relief” process of the material, which is called annealing treatment in some cases.

What Is Stress Relief Annealing Treatment?

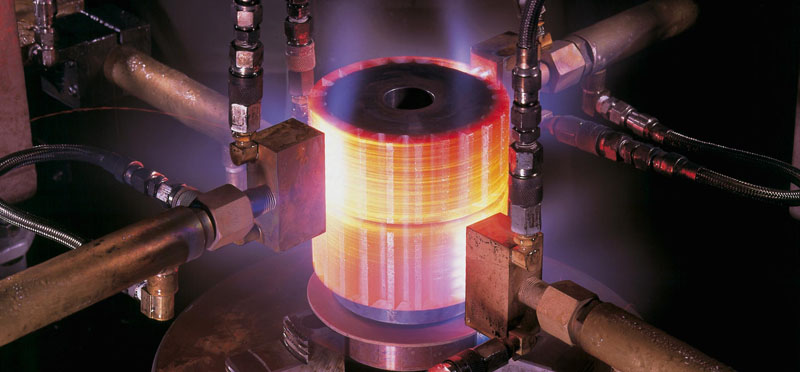

The process of heating the workpiece to a certain temperature, keeping it for a certain period of time and then cooling to restore the workpiece, thereby eliminating the residual internal stress is called stress relief annealing. The cold deformed metal is heated below the recrystallization temperature to remove the internal stress. But the heat treatment that still retains the effect of cold work hardening is called stress relief annealing.

Stress relief annealing is a heat treatment process that heats steel or various metal mechanical parts to a certain temperature, keeps it for a period of time, and then slowly cools it to obtain a heat treatment process that is close to the equilibrium state. In the machinery manufacturing industry, annealing is usually used as a preliminary heat treatment process in the manufacturing process of the workpiece.

In the actual processing and production process, the application of stress-relieving annealing process is more than the above-mentioned application. Hot forging, casting, various cold deformation processing, cutting or cutting, welding, heat treatment, and even after assembly of machine parts, without changing the structure state, retaining cold work, hot work or surface hardening conditions, the steel or machine The process of heating the parts at a lower temperature to remove (all or part of) internal stress and reduce the tendency of deformation and cracking can be called stress relief annealing. Due to the difference in material composition, processing method, internal stress size and distribution, and the difference in the degree of removal, the temperature range of stress relief annealing is very wide. Traditionally, the stress relief treatment at a higher temperature is called stress relief annealing, and the treatment at a lower temperature is called stress relief tempering. The essence is the same.

Principle Of Stress Relief Annealing

In the process of pressure processing, casting, welding, heat treatment, cutting processing and other processes, the product may generate internal stress. In most cases, after the end of the process, a part of the residual stress will remain in the metal. Residual stress can cause the workpiece to crack, deform or change in size. Residual stress also improves the chemical activity of the metal, and it is particularly easy to cause intergranular corrosion and cracking under the action of residual tensile stress. Therefore, the residual stress will affect the performance of the material or cause premature failure of the workpiece.

During stress relief annealing, the metal undergoes internal local plastic deformation (when the stress exceeds the yield strength of the material at this temperature) or a local relaxation process (when the stress is less than the yield strength of the material at this temperature) under a certain temperature. The residual stress is relaxed to achieve the purpose of elimination. During stress relief annealing, the workpiece is generally slowly heated to a lower temperature (500-550°C for gray cast iron, 500-650°C for steel, and below the recrystallization starting temperature for non-ferrous metal alloy stamping parts). After holding for a period of time, slowly Cool down to prevent new residual stress.

Stress-relief annealing can not completely eliminate the residual stress inside the workpiece, but only mostly eliminates it. To completely eliminate the residual stress, the workpiece needs to be heated to a higher temperature. Under such conditions, other organizational changes may be brought about, and the performance of the material may be compromised.

In addition to the size guarantee, the internal stress existing in the finished parts is actually very harmful. If it is not eliminated in time, the internal stress and the external loading force, that is, when the force applied during use is superimposed, it will cause the material to occur. Unexpected break. Therefore, the workpieces after casting, welding and cutting should be subjected to stress relief annealing to eliminate the internal stress generated during the processing, so when you are always working hard with the best craftsmanship and still cannot make good parts, or your customer tells you that the parts are accidentally broken during use, you can consider the stress annealing process, this process will help you solve many problems.