Author Archives: sansmachining

Performance Requirements And Selection Methods Of CNC Machining Tools

CNC tools are one of the prerequisites for improving machining efficiency. Today, we mainly introduce [...]

Mar

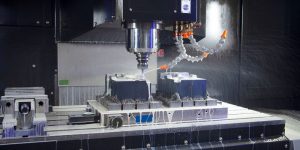

What Are The Characteristics Of CNC Machining Center Milling?

Machining center is a comprehensive equipment with milling machine, boring machine, drilling machine and other [...]

Mar

Why Leave Machining Allowances On CNC Machining Parts?

CNC machining is still a processing technology that is used more often. However, according to [...]

Mar

What Is The Difference Between An End Mill And A Keyway Mill?

Some people can't tell the difference between end mills and keyway milling cutters. Although their [...]

Mar

What Is Difference Between Sinker EDM And Wire EDM

EDM is a subtractive manufacturing technique that uses electrical discharge for machining. There are two [...]

Mar

Skills Of Machining Steps With Surface Grinding Machine

It is not difficult to process steps with a surface grinder. It should be noted [...]

Mar

Methods And Skills For Milling Stainless Steel

The characteristics of milling stainless steel are: the adhesion and fusion of stainless steel are [...]

Mar

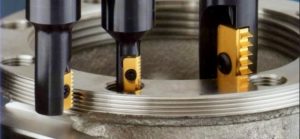

Methods And Skills For Milling Large Diameter Threaded Holes

Thread milling is the first choice if it is a large hole, i.e. a hole [...]

Mar

Why Are Non-standard Tools Important For Cutting?

In the process of machining, some situations that are difficult to process with standard tools [...]

Feb

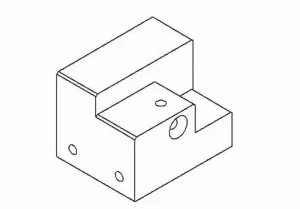

Engineering Drawing Basic Knowledge

In the broad concept of industrial design, engineering drawing or technical drawing is an essential [...]

Feb

Electropolishing VS Mechanical Polishing

Polishing refers to the use of mechanical, chemical or electropolishing action to reduce the surface [...]

Feb

A Common Method For Obtaining Workpiece Accuracy In CNC Machining!

Machining accuracy refers to the degree to which the actual geometric parameters (size, shape and [...]

Feb

How To Correctly Understand The Tool Life Of CNC Machining?

The service life of the general tool is 15-20 minutes of continuous processing of each [...]

Feb

What Is Case Hardening?

The ability to withstand wear and indentation are two very important attributes of certain types [...]

Feb

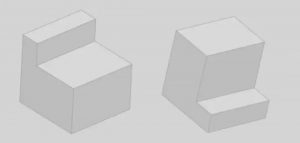

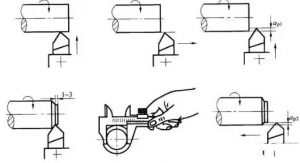

Skills Of Machining Steps With Surface Grinding Machine

It should be noted that the steps can be ground from two directions. The basis [...]

Feb

Summary Of The Skills Of Turning Thin-Walled Parts

In the cutting process, the thin wall is easily deformed by the cutting force, which [...]

Feb

How To Choose The Correct Tool Path Mode In CNC Milling?

This article analyzes the different characteristics of the cutting method and some factors that affect [...]

Jan

What Factors Affect The Low Cutting Force Efficiency Of CNC Milling Machines

Cutting force is an important basis for calculating cutting power, designing tools, machine tools and [...]

Jan