When working with hardened steel, selecting the right CNC machining tools is crucial for achieving precision, efficiency, and tool longevity. Hardened steel, typically with a hardness rating above 45 HRC, presents significant challenges due to its hardness and toughness. Here are some key considerations and recommendations for choosing better CNC machining tools for hardened steel:

1. Tool Material

Carbide Tools: Tungsten carbide tools are highly effective for machining hardened steel. They offer excellent hardness and wear resistance, making them suitable for high-speed applications.

Ceramic Tools: Ceramic tools can withstand extremely high temperatures and are ideal for finishing operations on hardened steel. They are less prone to thermal deformation, enhancing accuracy and tool life.

CBN (Cubic Boron Nitride) Tools: CBN cutting tools can process various types of hardened steel and sprayed parts, with a cutting speed of up to 100m/min and a surface roughness of Ra0.80-0.20 μm. The processing effect is worse than that of hard alloy (but the strength is not as good as hard alloy, the cutting depth is smaller, and the price is also more expensive than hard alloy. In addition, improper use can easily damage the cutting head).

2. Tool Coating

TiAlN (Titanium Aluminum Nitride): This coating enhances the tool’s hardness and oxidation resistance, making it suitable for high-speed machining of hardened steel.

AlTiN (Aluminum Titanium Nitride): AlTiN coatings provide excellent heat resistance and are ideal for dry machining operations.

Diamond-Like Carbon (DLC): DLC coatings offer low friction and high hardness, which can improve tool performance and longevity.

3. Tool Geometry

Sharp Cutting Edges: Sharp and well-defined cutting edges reduce cutting forces and minimize workpiece deformation.

Positive Rake Angles: Positive rake angles help in reducing cutting forces and improve chip evacuation, essential for machining hard materials.

Micro and Nano-Grain Carbide: Tools made from micro and nano-grain carbide offer better edge retention and wear resistance.

4. Cutting Parameters

Cutting Speed: While machining hardened steel, it’s crucial to use the appropriate cutting speed. High-speed cutting can generate excessive heat, leading to tool wear. Moderate cutting speeds are generally preferred.

Feed Rate: A lower feed rate helps in maintaining tool life and achieving better surface finish. However, it should be balanced to avoid excessive time consumption.

Depth of Cut: Smaller depths of cut are recommended to minimize tool stress and avoid premature tool failure.

5. Tool Runout

Tool runout is another important but frequently overlooked aspect in milling operations. In general, tool life is cut in half when runout exceeds 0.0004 inch. When using very small tools, minimizing runout becomes even more important.

It is not recommended to leave too much part stock for finish milling. For cutters with a diameter of about 1/8-inch and bigger, it is advisable to leave around 1% of the cutter diameter for finishing.

6. Coolant and Lubrication

High-Pressure Coolant: Using high-pressure coolant helps in efficient heat dissipation and chip evacuation, reducing the risk of tool overheating.

Cryogenic Cooling: Cryogenic cooling, using substances like liquid nitrogen, can significantly enhance tool life and surface finish when machining hardened steel.

7. Tool Holders and Stability

Rigid Tool Holders: Ensuring the rigidity of tool holders and the overall setup minimizes vibrations, which can affect surface finish and tool life.

Balanced Tool Assemblies: Properly balanced tool assemblies reduce runout and enhance machining accuracy, especially at higher speeds.

8. Specialized Tools

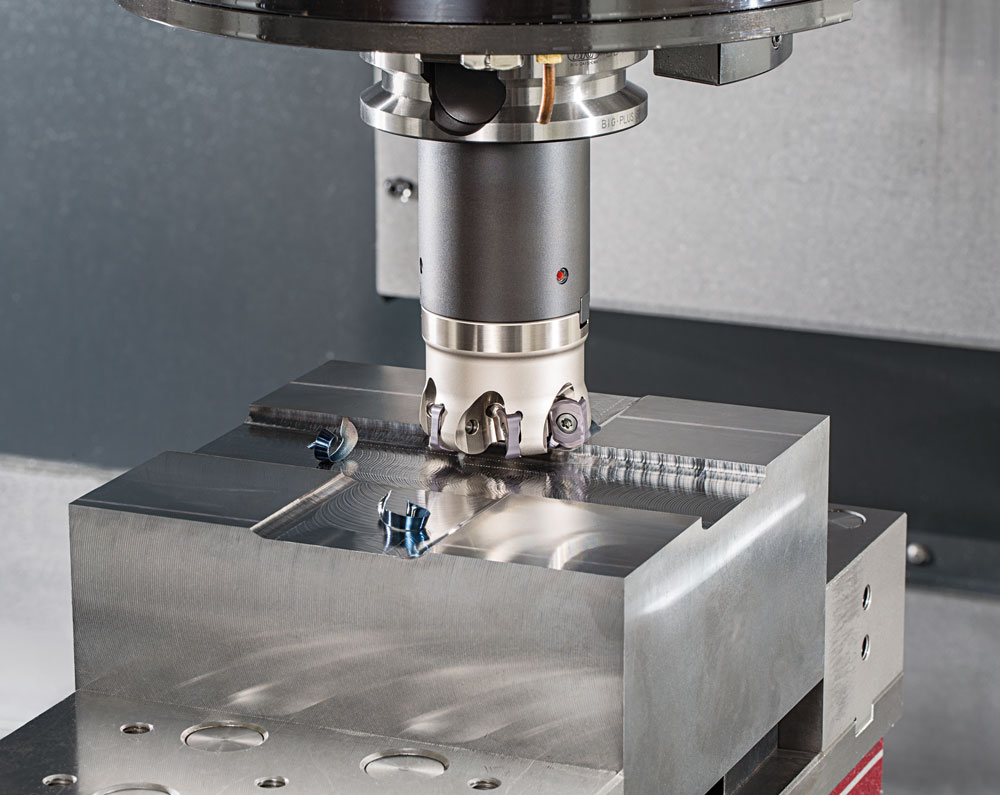

High-Performance End Mills: End mills designed specifically for hardened materials come with specialized geometries and coatings to improve performance.

Indexable Inserts: Using indexable inserts with appropriate coatings and edge preparation can be a cost-effective solution for machining hardened steel.

Conclusion

Machining hardened steel requires careful consideration of tool materials, coatings, geometries, and cutting parameters. By selecting the right combination of these factors, you can achieve superior machining performance, extend tool life, and produce high-quality components. Always consider the specific requirements of your application and the properties of the hardened steel you are working with to make the best tooling choices.