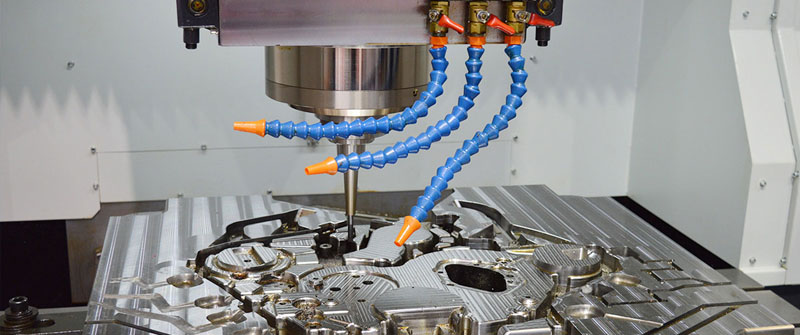

Milling is an important technology used in CNC precision machining, with applications in medical, aerospace, optical and mechanical parts. Milling uses rotating tools to remove material from the workpiece by feeding the workpiece at an angle relative to the tool axis. The instructions are input into the CNC machine tool through CAD files and converted into a set of precise sequence instructions. CNC machine tools use these programming commands to operate automatically without the need for a physical operator. Manufacturers have obtained many benefits through the application of CNC machining, such as reducing costs, increasing speed, improving accuracy and increasing productivity.

The axis of the milling machine determines the type of workpiece and the position that can be completed on the workpiece. These machines have at least 3 axes and run along the XYZ plane: X axis (vertical), Y axis (horizontal) and Z axis (depth). The 4th axis represents the A axis (rotation around the X axis), and the 5th axis represents the B axis (rotation around the Y axis).

Here, we look at the differences between 3-axis, 4-axis and 5-axis machining and the types and advantages of their applicable parts.

What is 3 Axis Machining?

3-axis machining is a milling process performed on the X and Y axes, which means that the workpiece remains in the same position, while the cutting tool operates along the XYZ plane to trim away the material. Since 3-axis machining can only be performed on 3-axis, it is relatively simple and can remove material from back to front, side to side, and top to bottom on these 3 axes. This is suitable for parts that do not require much depth and detail. Three-axis machining is most commonly used to produce mechanical parts, and is most suitable for:

- Automatic/interactive operation

- Slot milling

- Drilling

- Cut Sharp Edges

Although three-axis machining is the most basic process, depending on the production scale, workpiece requirements, precision and finishing constraints, materials used and clamping capabilities, three-axis machining may be the ideal choice for your machining project.

3-axis milling can produce the same products as 4-axis and 5-axis milling machines, but 3-axis milling machines cannot provide the same level of detail or efficiency. The 3-axis can cut a single feature during operation, but it cannot match the 5-axis work in terms of quality or profitability.

What is 4 Axis Machining?

4-axis milling involves the same process involved in 3-axis machining, where a cutting tool is used to remove material from the workpiece to create the desired shape and contour. However, in four-axis machining, milling is performed on the additional axis. A 4-axis CNC machine tool runs on the X, Y, and Z axes like a 3-axis machine tool, but it also includes rotation around the X axis (called A axis). This is the 4th axis added during our machining process. In most cases, the workpiece will rotate to allow cutting around the B axis.

4-axis milling involves the same process involved in 3-axis machining, where a cutting tool is used to remove material from the workpiece to create the desired shape and contour. However, in four-axis machining, milling is performed on the additional axis. A 4-axis CNC machine tool runs on the X, Y, and Z axes like a 3-axis machine tool, but it also includes rotation around the X axis (called A axis). This is the 4th axis added during our machining process. In most cases, the workpiece will rotate to allow cutting around the B axis.

4-axis milling is useful when holes and cuts need to be made on the side of the workpiece or around the cylinder. They can provide fast and efficient work based on computer digital input to obtain accurate results. Can be used in multiple industries, including Industry, Technology Research, Teaching, Hobby Prototype Building, Advertising Design, Creating Art, Medical Equipment Creation, etc.

The additional fourth axis (A axis) can automatically turn the workpiece, so the machine can remove material from both sides. Four-axis machining is versatile and can be used for:

- Intermittent cutting

- Continuous cutting

- Carved surface

What is 5 Axis Machining?

5-axis machining means that the workpiece can be automatically operated from five sides at once. In addition to automatic movement along X, Y and Z axes, 5-axis CNC machine tools can also select two of the three rotation axes (A, B, C) for use. The A, B and C axes perform 180° rotation around the X, Y and Z axes respectively. This type of machining is used in the automotive, aerospace and boating industries. Usually very suitable for extremely complex components that are solid and must be cast.

5-axis machining requires longer preparation time for CNC programming to adapt to complex rotary motions, but allows machining on all five sides of a workpiece in one operation. This multi-dimensional rotation and tool movement make the B-axis in the production of the workpiece With unparalleled precision, finish and speed. Able to create precise and complex parts for artificial bones, aerospace products, titanium parts, oil and gas machinery parts, automotive molds, medical, construction and military products.

Do not confuse 5-axis indexing milling with true 5-axis machining. Five-axis indexing machining is also called 3 + 2 machining, which cannot maintain continuous contact between the cutting tool and the workpiece on all rotating axes. Real 5-axis machining simultaneously uses the three linear axes (X, Y, and Z) and two rotary axes (A and B) of the machine tool, resulting in more complex contour surface machining.

5-axis indexing is very suitable for parts that do not require extreme contour control, such as fixtures, fixtures, housings and other components often used in manufacturing. If you need to make a design with excellent functionality, then true 5-axis machining may be your best choice.

Configuration for 5-axis machining

There are two main configurations for a five-axis machine tool:

Rotary rotary type: These machines utilize the rotating shaft by rotating the main shaft. This style is best for processing heavier parts because the workbench is always level.

Trunnion type: The trunnion type machine has a movable worktable, which is very useful for processing large volumes, because the spindle does not take up space.

The specific type of machine used depends on various factors of your work, including the weight of parts and the number of finished products.

Advantages of 5-axis machining:

Reduce Processing Time

In five-axis machining, the flat-bottomed end mill is used to maintain a vertical state for the complex mold processing surface, which can greatly reduce the processing time. The principle of the five-axis machining center is also suitable for side milling with angled surfaces, which can eliminate rib-like textures caused by ball end milling, making the surface quality of the mold more ideal, and reducing the need for cleaning the mold surface The workload of manual milling and manual work.

Complex Design

The additional motion available in 5-axis machining allows you to achieve complex shapes and designs. With a five-axis machine tool, you can access machining angles and arcs that were previously only possible with multiple settings and countless special fixtures. Ultimately, five-axis machining eliminates the need to create complex fixtures, because you can fix the part at a time and rotate it in a single process to obtain the desired geometry.

Improve Machining Accuracy

Through the five-axis machining technology, the problem that the workpiece needs to be repositioned at a complex angle and needs to be debugged multiple times is solved, which not only shortens the time, but also greatly reduces the error generated. The tooling fixture required when installing the workpiece The large amount of cost has also been saved, and the machine tool has also achieved the processing of complex parts, such as the drilling, taper processing, and cavity recesses required for complex surfaces, which are not possible with traditional methods.

Faster Material Removal

In 5-axis machining, the cutting tool stays tangent to the cutting surface, thus shortening the cycle time, which helps save costs because you have to remove more material each time you cut the tool.

Better Surface Finish

The fourth and fifth axis can help you orient the part and bring the part closer to the cutting tool, allowing you to use a shorter cutting tool that is not susceptible to vibration at extremely high cutting speeds, thus helping you get Better surface finish.

High Productivity

The five-axis machining center can effectively reduce the machining time and auxiliary time of the parts. The five-axis linkage machining center has a wide range of spindle speed and feed, allowing the machine tool to perform powerful cutting with a large amount of cutting. The five-axis linkage machining center is currently entering In the era of high-speed machining, the rapid movement and positioning of moving parts of the five-axis machining center and high-speed cutting processing have reduced the turnaround time between semi-finished products and improved production efficiency.

Although the advantages of five-axis compared with 4-axis and 3-axis are very prominent, not all products are suitable for five-axis processing, and those suitable for three-axis processing are not necessarily suitable for five-axis processing. If you use products that can be processed by three-axis Five-axis machining will not only increase the cost, but the effect is not necessarily good. Only by making reasonable arrangements and formulating suitable machine tools for the product can the value of the machine itself be brought into play.

If you don’t know which method is suitable for your project, please send us the information, and our professional technical team will give you the most professional and suitable solution.