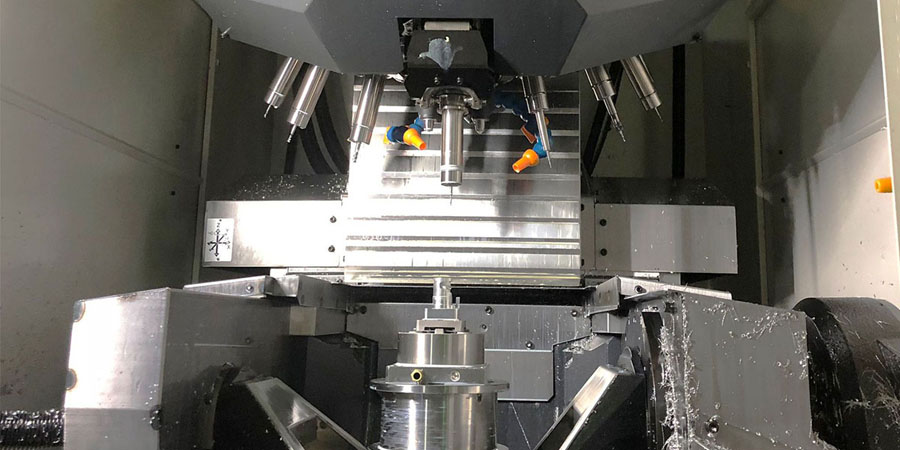

CNC machining has revolutionized the manufacturing processes across various industries, and the automotive sector is no exception. The precision, efficiency, and versatility of CNC machining make it a critical component in the production of automotive parts. Here’s a closer look at the role of CNC machining in automotive production lines.

1. Precision and Accuracy

High Tolerance Levels: CNC machining allows for the production of parts with extremely high tolerance levels, which is essential for the functionality and safety of automotive components. This precision ensures that each part fits perfectly and performs reliably.

Consistent Quality: CNC machines are controlled by computer programs, ensuring that each part is produced to the exact specifications every time, leading to consistent quality and reduced error rates.

2. Efficiency and Speed

Reduced Production Time: CNC machining significantly reduces production time compared to traditional manual methods. This is particularly important in the automotive industry, where meeting production deadlines is critical.

Automation: The automation capabilities of CNC machines allow for continuous operation, including lights-out manufacturing, where machines can run unattended, further increasing efficiency.

3. Versatility in Material Use

Diverse Materials: CNC machines can work with a wide range of materials, including metals (aluminum, steel, titanium) and plastics. This versatility is crucial in automotive manufacturing, where different parts require different materials based on their function and performance requirements.

4. Complex Geometries and Customization

Complex Part Production: CNC machining can produce parts with complex geometries that would be difficult or impossible to create with other methods. This capability is essential for the intricate components often found in automotive engines and other systems.

Customization: CNC machines can be quickly reprogrammed to produce custom parts or small production runs, which is beneficial for prototype development and testing in the automotive industry.

5. Reduction in Waste

Material Efficiency: CNC machining is highly efficient in terms of material usage, as it can minimize waste by optimizing the cutting process. This not only reduces material costs but also contributes to more sustainable manufacturing practices.

6. Integration with CAD/CAM Software

Seamless Integration: CNC machining integrates seamlessly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration allows for the direct translation of design files into machined parts, streamlining the production process and reducing the risk of errors.

7. Prototyping and Innovation

Rapid Prototyping: CNC machining is ideal for rapid prototyping, allowing automotive manufacturers to quickly develop and test new designs. This accelerates the innovation cycle and helps bring new products to market faster.

Iterative Testing: Prototypes can be iterated and refined quickly, enabling engineers to test and improve designs efficiently before committing to large-scale production.

8. Cost-Effectiveness

Long-Term Savings: While the initial investment in CNC machinery can be high, the long-term savings in labor, material, and time make it a cost-effective solution for automotive manufacturers.

Reduced Labor Costs: Automation reduces the need for manual labor, which can significantly lower production costs over time.

9. Quality Control and Inspection

In-Process Inspection: CNC machines can be equipped with in-process inspection tools, such as probes, to measure and verify dimensions during production. This ensures that parts meet quality standards and reduces the need for post-production inspection.

Traceability: CNC machining allows for detailed tracking and traceability of each part produced, which is essential for quality control and meeting regulatory standards in the automotive industry.

Conclusion

CNC machining is an indispensable part of the automotive production line, offering unparalleled precision, efficiency, and versatility. Its ability to produce high-quality parts with complex geometries, combined with the benefits of automation and material efficiency, makes it a cornerstone of modern automotive manufacturing. As the industry continues to evolve, the role of CNC machining is likely to expand, driving further innovation and improvement in automotive production processes.