CNC machining is a vital technology in the food and beverage industry, where precision, hygiene, and efficiency are paramount. CNC machining enables the production of high-quality components that are essential for the smooth operation of machinery used in food processing, packaging, and handling. This post explores how CNC machining is applied in the food and beverage industry and the benefits it brings to the production line.

Applications of CNC Machining in the Food and Beverage Industry

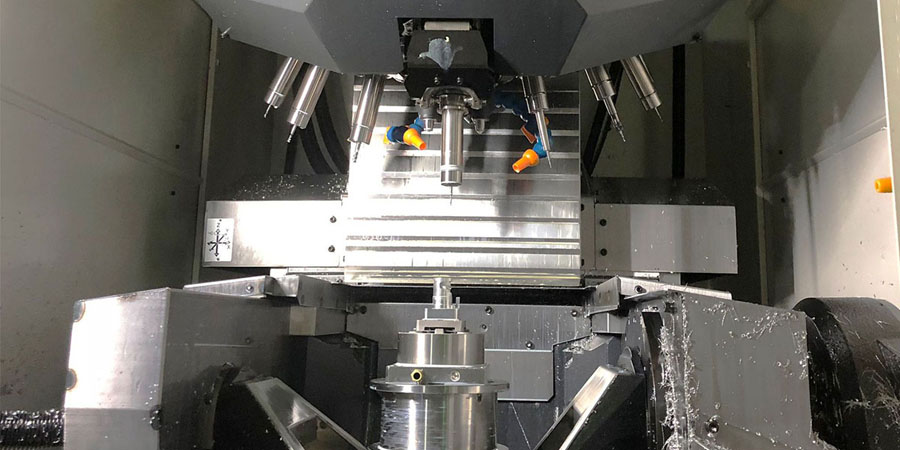

CNC machining is used to create a wide range of components for food and beverage production machinery, including:

Processing Equipment Parts:

CNC machining produces parts for food processing equipment such as mixers, grinders, slicers, and conveyors. These components must be made with high precision to ensure consistent performance and meet the industry’s strict hygiene standards.

Packaging Machinery Components:

CNC machining is essential for creating parts for packaging machines, including fillers, sealers, and cappers. Accurate machining ensures that packaging is airtight and maintains the quality and safety of food products.

Custom Tooling:

CNC machining allows for the creation of custom tools and molds used in the food and beverage industry, such as cookie cutters, bottle molds, and die sets for forming packaging materials.

Pumps and Valves:

CNC machining is used to manufacture pumps and valves that control the flow of liquids and gases in food and beverage production. These components must be durable and corrosion-resistant to withstand the harsh conditions often found in the industry.

Hygienic Components:

The food and beverage industry requires components that are easy to clean and resistant to contamination. CNC machining produces smooth, crevice-free surfaces that are essential for maintaining hygiene in food contact parts.

Materials Used in CNC Machining for the Food and Beverage Industry

The choice of materials is critical in the food and beverage industry due to the need for safety, durability, and corrosion resistance. Common materials used in CNC machining for this industry include:

Stainless Steel:

Stainless steel is the most commonly used material due to its excellent corrosion resistance, ease of cleaning, and non-reactivity with food products. It is ideal for components that come into direct contact with food.

Food-Grade Plastics:

Materials such as PTFE (Teflon), UHMWPE, and PEEK are often used for parts that require low friction, chemical resistance, and non-stick properties. These plastics are also FDA-approved for food contact.

Aluminum:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it suitable for parts that require heat dissipation or are used in low-temperature environments.

Advantages of CNC Machining in the Food and Beverage Industry

CNC machining offers several advantages that make it ideal for producing components in the food and beverage industry:

Precision and Consistency:

CNC machines are capable of producing parts with high precision and repeatability, ensuring consistent performance across all components in the production line.

Customization:

CNC machining allows for the creation of custom parts tailored to specific applications in food and beverage machinery. This flexibility is crucial for developing new products and adapting to changing industry needs.

Hygiene:

CNC machining produces parts with smooth surfaces and minimal crevices, reducing the risk of contamination and making them easier to clean. This is vital for maintaining the strict hygiene standards required in the industry.

Durability: Parts produced through CNC machining are known for their durability and resistance to wear and corrosion, which is essential for the demanding environments in food and beverage production.

Efficiency:

CNC machining is highly efficient, enabling the rapid production of parts with minimal waste. This helps reduce lead times and costs, ensuring that the production line operates smoothly and without delays.

Challenges and Consideration

While CNC machining offers numerous benefits, there are also challenges to consider:

Enhanced packaging solutions

Packaging plays a crucial role in the food and beverage industry, influencing various aspects from product preservation to consumer appeal. CNC machining helps manufacture precision molds and dies for packaging production. These tools ensure the manufacturing of packaging components such as bottles, caps, and containers with high precision and consistency.

Meet regulatory standards

The food and beverage industry is strictly regulated to ensure consumer safety. CNC machining helps manufacturers comply with these strict regulations by producing parts and equipment that meet the highest quality and hygiene standards. The precision and repeatability of CNC machining ensure that components are always produced according to the required specifications, thereby reducing the risk of non-compliance.

Material Selection:

Choosing the right material for CNC machined parts is critical, especially in the food and beverage industry, where safety and compliance with regulatory standards are essential.

Design Complexity:

Some parts in the food and beverage industry may have complex geometries that require advanced CNC machining techniques and careful planning to ensure accurate production.

Conclusion

CNC machining plays a crucial role in the food and beverage industry, enabling the production of high-quality, precise, and hygienic components that are essential for efficient and safe food production. By leveraging the capabilities of CNC machining, manufacturers in the food and beverage industry can ensure that their production lines operate at peak performance, delivering consistent and reliable results while meeting the industry’s stringent standards.