The situation in 2020 has accelerated technological innovation in the CNC industry. With increasing attention to automation and waste reduction, coupled with an urgent sense of urgency, 2021 is expected to bring about a series of exciting trends that will change the face of the CNC industry.

Below are 6 CNC trends that may emerge in 2021.

1. Manufacturing As A Service Will Continue Gaining Popularity

Manufacturing as a service (MaaS) has entered the CNC industry in recent years, but as we develop in the foreseeable future, it is expected to gain wider acceptance. Since the CNC machine is placed in a central location, MaaS uses network resources to complete manufacturing tasks, and the operation, maintenance and repair costs are evenly distributed to its subscribers.

The manufacturing-as-a-service option provides companies with greater productivity, flexibility, agility and cost savings by reducing labor expenditures. As the impact of the Covid-19 pandemic continues, expect companies to explore an expanded supply chain network through MaaS.

2. The Internet Of Things Will Dominate Emerging Technologies

IIoT stands for “Industrial Internet of Things”. IIoT allows networked CNC machines to communicate with each other without manual operation. The Industrial Internet of Things (IIoT) is a digitally automated process that connects the factory floor and accumulates real-time data about the environment, efficiency, performance, and operating conditions of each function in the facility.

Although the CNC machine is smart enough with its CNC software, by adding sensors and combining them with the factory unit via the Internet, the CNC machine will generate data about the status of the equipment and the efficiency of the production process, productivity levels and energy consumption. All of these will directly affect the company’s profitability.

In addition, by using the data collected from CNC machine tools using IIoT, the company will know the exact production rate for any given number of seconds. When the device is not in use, the device will automatically shut down the engine to save energy costs, identify when the part is approaching its useful life, and assume the exact power required to manufacture the different components.

We expect that as the CNC industry will continue to seek effective methods to improve efficiency and reduce material waste, the level of process automation in 2021 will be even higher.

3. The Application Of 6-Axis Machining Will Expand Rapidly

We predict that the 6-axis CNC milling machine, which first appeared at the end of 2019, will become the next big thing in the CNC industry. After all, the greater the number of axes, the shorter the production time. For now, the biggest CNC machining revolution in the next decade may be the 6-axis machining method.

Multi-axis machining involves a specific CNC machine tool moving in four or more directions to enhance the ability of raw material finishing. It uses a milling program to remove excess raw material from the machine and produce a final product.

At present, most CNC machine tools provide three to five axis support. This means that the tool can process products in three dimensions (x, y, and z). The 5-axis machine tool can seamlessly rotate around the X-axis and Y-axis, and the 6-axis CNC machine tool will allow further rotation around the z-axis, thus shortening the cutting time.

In the next period of time, we can expect that more and more real manufacturers and third-party CNC processing plants will turn their attention to 6-axis CNC machine tools, which will prove to be high-precision production of aerospace and automotive parts. The ideal choice for large mechanical parts such as components requires the highest possible accuracy. 6-axis CNC machine tools will surely become a must-have product in the industry in the near future.

4. Will Pay More Attention To Waste Reduction

Not surprisingly, COVID-19 has plunged the global supply chain into chaos. Although raw materials have always been a precious resource, by 2021, people will pay more attention to the wise use of materials. One strategy is to use 3D printing methods to create scale models of parts, rather than design experiments on actual CNC equipment.

5. Proficient Personnel Will Become More Important In The CNC Industry

More and more people are panicking that automation and technology are taking people’s jobs from production facilities, but this is far from reality. There is no doubt that machines have greatly reduced employment in manufacturing companies.

However, there is still a huge demand for skilled employees who need to keep up with the most advanced CNC machining trends and simplify the manufacturing process.

Skilled and skilled manufacturing machinists and experts will become valuable assets of any production company. They will become the decisive factor in the company’s development in the next ten years.

In addition to having the latest manufacturing technologies, these organizations also need highly skilled employees to use them efficiently, and these will never change.

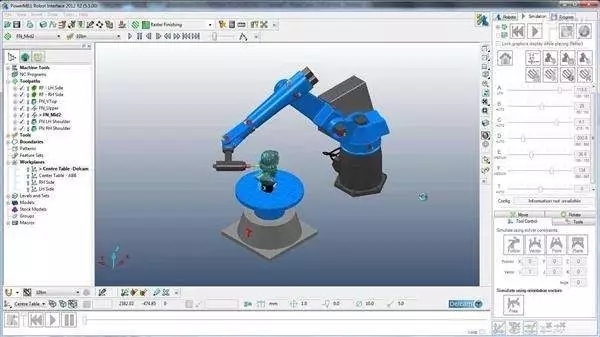

6. A Large Number Of CAM Software Upgrades

Computer-aided manufacturing (CAM) software is an important part of CNC machining, which integrates computer-aided design (CAD) design into a virtual system. The CAM software determines the best settings and sequence for the machine to minimize the possibility of errors or suboptimal parts.

One of the latest features included in CAM software as a standard is conflict disclosure. As machines become more and more complex and more axes are introduced, the margin for errors and collisions is more important than ever.

A large number of CAM software upgrades are expected here. These software improvements will have great benefits for new CNC machining staff, because they should still develop skills that can predict such failures and setbacks.

Thanks to the new CAM software version, these employees only need to let the software estimate the given running volume of the machine tool, and then they can easily operate the CNC equipment.

It is expected that in the next few years there will be a lot of software development and improvement, because this inevitably and skilled personnel will become more critical than ever. Experienced CNC programmers, software developers and operators will do a lot of work in the future

The Future Of Machining In 2021 And Beyond

Despite the unexpected disruption of the market this year, CNC manufacturing is still an essential and booming industry. To adapt to future crises, the company is turning to automated manufacturing methods to ensure that its resources and products are managed wisely. Global companies must turn to automated manufacturing solutions such as IIoT, technological advancements such as 6-axis CNC tools, use advanced software, utilize third-party CNC manufacturing solutions, and invest in employee education to ensure wise management of their products and resources . It is expected that more advancements in CNC machinery will lead the development in 2021 and beyond.