With the rapid development of modern manufacturing industry, CNC turning technology has become one of the key technologies in the field of precision non-standard parts manufacturing. CNC turning precision non-standard parts with its high precision, high efficiency, high flexibility and other advantages, plays an irreplaceable role in many industries such as aerospace, automobile manufacturing, mold manufacturing, medical equipment, etc. This article will discuss the CNC turning precision non-standard parts from the aspects of the characteristics, application, process flow and future development trend of CNC turning technology.

1. Characteristics of CNC Turning Technology

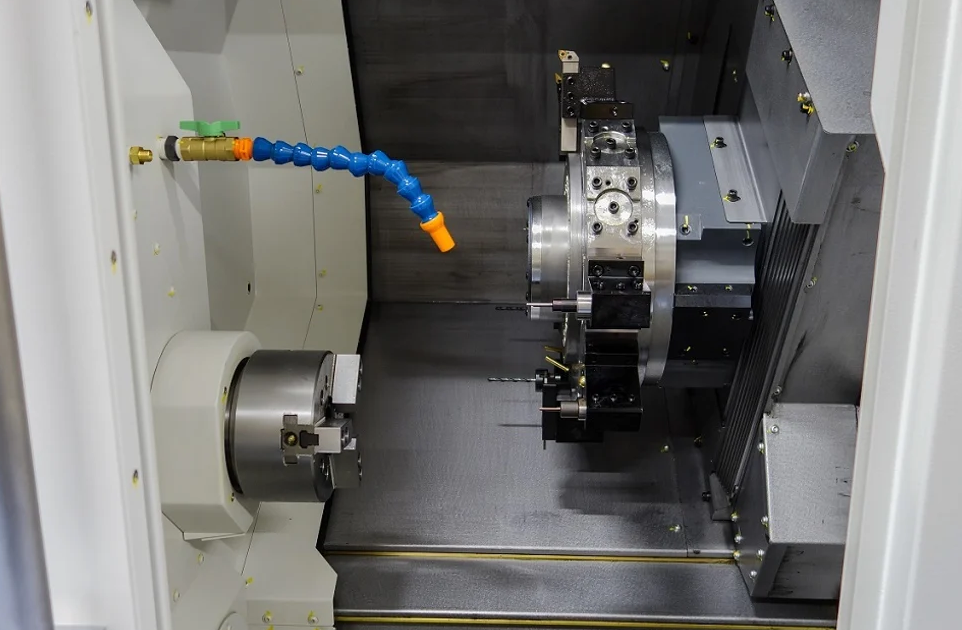

CNC turning technology is to realize the automatic processing of workpieces through the movement of computer digital control machine tools. Its characteristics are mainly reflected in the following aspects:

- High precision:

CNC lathe adopts precise control system and servo system, which can achieve micron or even nanometer processing accuracy to meet the manufacturing needs of high-precision parts.

- High efficiency:

The CNC turning process has a high degree of automation and can work continuously for 24 hours, which greatly improves production efficiency. At the same time, by optimizing cutting parameters and processing paths, the processing time can be further shortened.

- High flexibility:

CNC lathes can process workpieces of various complex shapes. Through programming, they can realize a variety of processing methods, such as milling, drilling, tapping, turning, etc., with strong adaptability.

- High reliability:

CNC lathes use advanced fault diagnosis and early warning systems, which can monitor the operation status of machine tools in real time, detect and handle faults in time, and ensure the stability and reliability of the processing process.

2. Application of CNC Turning

CNC turning technology has a wide range of applications in the field of precision non-standard parts manufacturing. The following are some typical application cases:

- Aerospace field:

In the aerospace field, the manufacturing requirements of precision non-standard parts are extremely high. CNC lathes can process various complex parts, such as engine blades, turbine discs, guide blades, etc., to meet the high precision, high strength and high reliability requirements of aerospace products.

- Automobile manufacturing field:

Automobile manufacturing involves a large number of precision non-standard parts, such as engine cylinders, crankshafts, camshafts, etc. CNC turning can achieve efficient and high-precision processing of these parts, improving the performance and reliability of automobiles.

- Mold manufacturing field:

Mold manufacturing is one of the important application fields of CNC turning technology. CNC lathes can process various complex mold parts, such as cavities, cores, sliders, etc., to meet the high precision and high efficiency requirements of mold manufacturing.

3. Process of CNC Turning Precision Non-standard Parts

The process of CNC turning precision non-standard parts generally includes the following steps:

- Drawing design:

According to product requirements, design drawings to determine the shape, size, tolerance and other parameters of the workpiece.

- Material preparation:

Select suitable materials, perform pre-treatment such as cutting and grinding, and prepare for processing.

- Programming setting:

According to the drawing requirements, use CNC programming software for programming setting and generate processing procedures.

- Machine tool debugging:

Debug the CNC lathe to ensure that the various parameters of the machine tool meet the processing requirements.

- Processing process:

Install the workpiece on the CNC lathe and process it according to the processing procedure. During the processing process, it is necessary to monitor the machine tool operation status and workpiece processing quality in real time.

- Quality inspection:

Perform quality inspection on the finished workpiece, including dimension measurement, shape inspection, surface quality assessment, etc., to ensure that the workpiece meets the quality requirements.

- Packaging and delivery:

Pack qualified workpieces and deliver them according to customer requirements.

4. Future Development Trend Of CNC Turning Precision Non-standard Parts

With the continuous development and transformation and upgrading of the manufacturing industry, the application of CNC turning technology in the field of precision non-standard parts manufacturing will be more extensive. In the future, the development trend of CNC turning technology will be mainly reflected in the following aspects:

- Intelligence:

By introducing advanced technologies such as artificial intelligence and the Internet of Things, the intelligent control and management of CNC lathes can be realized, and the automation and intelligence level of the processing process can be improved.

- Composite:

Integrate multiple processing functions on a CNC lathe to realize a one-machine multi-function processing method and improve the utilization rate and processing efficiency of the equipment.

- Precision:

By adopting more advanced control systems, servo systems and measurement technologies, the processing accuracy and stability of CNC lathes can be further improved to meet the manufacturing needs of higher precision.

- Environmental:

Pay attention to environmental protection and energy saving during the processing, adopt green manufacturing technology and processes, reduce energy consumption and waste emissions during the processing, and achieve sustainable development.

In short, CNC turning is one of the indispensable important technologies in modern manufacturing. With the continuous advancement of technology and the continuous expansion of application fields, CNC turning technology will play a more important role in the future.