Machining accuracy refers to the degree to which the actual geometric parameters (size, shape and position) of the part after processing conform to the ideal geometric parameters specified in the drawing. The higher the degree of conformity, the higher the machining accuracy.

In machining, due to the influence of various factors, it is actually impossible to process every geometric parameter of the part to exactly match the ideal geometric parameter, and there will always be some deviations. This deviation is machining error.

Explore from the following three aspects:

- Method of obtaining part dimensional accuracy

- Method of obtaining shape accuracy

- Method of obtaining position accuracy

1.Method Of Obtaining Part Dimensional Accuracy

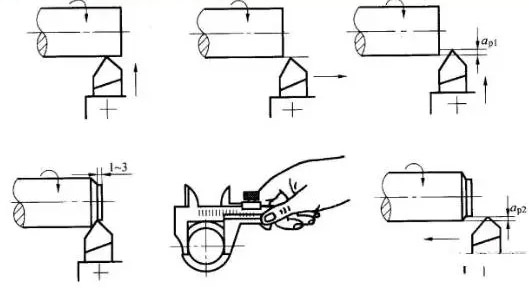

(1) Trial Cutting Method

That is, first try to cut out a small part of the machined surface, measure the size of the test cut, adjust the position of the cutting edge of the tool relative to the workpiece according to the machining requirements, and then try to cut, and then measure, so after two or three trial cuts and measurements, when it is processed after the size meets the requirements, cut the entire surface to be machined.

The trial cut method is through “trial cut-measurement-adjustment-trial cut again”, and repeats until the required dimensional accuracy is reached.

The precision achieved by the trial-cut method may be very high. It does not require complicated devices, but this method is time-consuming (requiring multiple adjustments, trial cuts, measurements, and calculations), low efficiency, and depends on the skill level of the workers and the accuracy of measuring instruments. The quality is unstable, so it is only used for single-piece small batch production.

As a type of trial-cutting method-matching, it is based on the processed part, processing another matching workpiece, or combining two (or more) workpieces together for processing. The requirements of the final processed size in the matching work are based on the matching requirements with the machined parts.

(2) Adjustment Method

Use sample or standard parts to adjust the accurate relative positions of machine tools, fixtures, cutting tools and workpieces to ensure the dimensional accuracy of the workpieces. Because the size is adjusted in advance, there is no need to try cutting again during machining. The size is automatically obtained and remains unchanged during the machining of a batch of parts. This is the adjustment method. For example, when using a milling machine fixture, the position of the tool is determined by the tool block. The essence of the adjustment method is to use the fixed distance device or the tool setting device on the machine tool or the pre-set tool holder to make the tool reach a certain position accuracy relative to the machine tool or fixture, and then process a batch of workpieces.

It is also a kind of adjustment method to feed the tool according to the dial and then cut on the machine tool. This method needs to determine the scale on the dial according to the trial cut method. In mass production, tool setting devices such as fixed-range stoppers, prototypes, and templates are often used for adjustment.

The adjustment method has better machining accuracy and stability than the trial cutting method, and has higher productivity. It does not require high machine tool operators, but has high requirements for machine tool adjusters, and is often used in batch production and mass production.

(3) Fixed Size Method

The method of using the corresponding size of the tool to ensure the size of the workpiece to be machined is called the sizing method. It uses standard-sized tools for machining, and the size of the machined surface is determined by the tool size. That is, a tool with a certain dimensional accuracy (such as reamer, reamer, drill, etc.) is used to ensure the accuracy of the workpiece (such as hole).

The sizing method is easy to operate, has high productivity, and the machining accuracy is relatively stable. It has almost nothing to do with the technical level of the workers. It has high productivity and is widely used in various types of production. For example, drilling, reaming, etc.

(4) Active Measurement Method

During the machining process, the machining dimensions are measured while machining, and after the measured results are compared with the dimensions required by the design, either the machine tool can continue to work, or the machine tool can be stopped. This is the active measurement method.

Currently, the values in active measurement can be displayed digitally. The active measurement method adds the measurement device to the process system (that is, the unity of machine tools, cutting tools, fixtures and workpieces) and becomes its fifth factor.

Active measurement method has stable quality and high productivity, which is the development direction.

(5) Automatic Control Method

This method is composed of measuring device, feeding device and control system. It combines the measuring, feeding device and control system into an automatic processing system, and the machining process is automatically completed by the system.

A series of tasks such as size measurement, tool compensation adjustment, cutting processing, and machine stoppage are automatically completed, and the required size accuracy is automatically achieved. For example, when machining on a CNC machine, parts are controlled by various instructions of the program to control the machining sequence and machining accuracy.

The initial automatic control method was completed by using active measurement and mechanical or hydraulic control systems. At present, pre-arranged programs according to processing requirements have been widely used. Programs that are issued by the control system to control machine tools or digitally controlled machine tools that are issued by the control system to perform digital information instructions, and can adapt to changes in processing conditions during machining, automatically adjust the processing amount and realize the optimization of the machining process according to the specified conditions. The adaptive control machine tool performs automatic control processing.

The automatic control method has stable quality, high productivity, good machining flexibility, and adaptability to multi-variety production, which is the current development direction of mechanical manufacturing and the basis of computer-aided manufacturing (CAM).

2. Method Of Obtaining Shape Accuracy

(1) Trajectory Method

This machining method uses the trajectory of the tool tip movement to form the shape of the machined surface. Ordinary turning, milling, planing and grinding all belong to the tool tip path method. The shape accuracy obtained by this method mainly depends on the accuracy of the forming movement.

(2) Forming Method

Use the geometry of the forming tool to replace certain forming movements of the machine tool to obtain the shape of the machined surface. Such as forming turning, milling, grinding, etc. The shape accuracy obtained by the forming method mainly depends on the shape of the blade.

(3) Generating Method

Use the envelope surface formed by the tool and the workpiece to generate the shape of the machined surface, such as gear hobbing, gear shaping, gear grinding, knurling spline, etc. are all generative methods. The shape accuracy obtained by this method mainly depends on the shape accuracy and generative motion accuracy of the blade.

3. Method Of Obtaining Position Cccuracy

In machining, the accuracy of the position of the processed surface on other surfaces is mainly determined by the clamping of the workpiece.

(1) Directly Find The Correct Clamping

This method is to use a dial indicator, a marking plate or visual inspection to directly locate the workpiece on the machine tool.

(2) Draw The Line To Find The Correct Installation Clamp

This method is to first draw the center line, symmetry line and the processing line of each surface to be processed on the blank according to the part drawing, and then install the workpiece on the machine tool, and align the clamping position of the workpiece on the machine tool according to the drawn line.

This clamping method has low productivity, low accuracy, and high technical requirements for workers. It is generally used for processing complex and heavy parts in small batch production, or when the blank size tolerance is large and cannot be directly clamped by fixtures.

(3) Clamping With Clamps

The fixture is specially designed in accordance with the requirements of the machining process. The positioning elements on the fixture can quickly occupy the correct position of the workpiece relative to the machine tool and the cutting tool. The positioning accuracy of the workpiece can be ensured without alignment, and the clamping productivity with the fixture is high. The positioning accuracy is high, but special fixtures need to be designed and manufactured, which are widely used in batch and mass production.