When engaged in mechanical design, there are often thread features in the part drawing. In addition to drawing the thread in a standardized way, you also need to mark it correctly to ensure that the processed parts are what you want and that there is no error in assembly. In addition, threaded standard parts are often used in assembly drawings, and they also need to be correctly marked in the schedule so that the purchasing department can purchase them correctly. When other personnel read mechanical drawings, they also need to understand the marking of threads.

Therefore, the knowledge of thread marking is a necessary skill for those engaged in the fastener industry. This article will mainly introduce the marking of various threads.

1. Ordinary Thread

Ordinary thread is the most widely used thread in life and work. Most threads on threaded fasteners (bolts, studs, screws, nuts and other parts) are ordinary threads.

Ordinary thread is divided into coarse thread and fine thread. Fine thread ordinary threads are mostly used on precision parts and thin-wall parts (for example, ordinary threads used in hydraulic pipe joints are fine threads).

In the marking of threads, the pitch of fine tooth ordinary threads must be indicated, while the pitch of coarse tooth ordinary threads is generally not marked (because fine tooth ordinary threads with the same diameter may have a variety of pitches, while the pitch of coarse teeth is certain). The pitch of common thread is described in detail in the national standard (gb/t 193 common thread diameter and pitch series).

The complete marking of ordinary threads consists of five parts:

For example: M10 × 1 ― 7H ― L ― LH

(1) Feature code and size code of ordinary thread

Feature code: M (for ordinary thread).

Size code: nominal diameter × Pitch (the lead and pitch of multi thread shall be indicated, and the pitch of single thread coarse thread ordinary thread is not marked).

“M10” refers to single thread coarse thread with nominal diameter of 10 mm and pitch of 1.5 mm.

“M10 × 1 “refers to single thread fine tooth ordinary thread with nominal diameter of 10mm and pitch of 1 mm.

(2) Code of tolerance zone for ordinary thread

The tolerance zone code of ordinary thread is composed of tolerance grade (number) and basic deviation (external thread is represented by lowercase letters and internal thread is represented by capital letters), such as 5g6g, 6G, 6h, 7h.

When the codes of the pitch diameter tolerance zone and the top diameter tolerance zone of the thread are different, they need to be noted separately, such as M10 – 5g6g (5g is the code of the pitch diameter tolerance zone, 6G is the code of the top diameter tolerance zone).

When the middle diameter and top diameter tolerance zone codes are the same, only one code is noted, such as M10 × 1―7H。 When the tolerance zone code is 6G or 6h (nominal diameter ≥ 1.6mm), it is not marked (when the tolerance zone of ordinary thread is not marked, the default tolerance zone is 6G or 6h). The content of tolerance grade and basic deviation will be introduced in later articles.

(3) Thread engagement length

There are three kinds of screwing lengths of ordinary threads: long, medium and short, which are represented by codes L, N and s respectively.

For example, m10-5g6g-s is the thread with short screw length, and m10-7h-l is the thread with long screw length. When the thread is of medium screwing length, the code n is not marked.

In case of special needs, the value of screwing length can be indicated. For example: M20 × 2―5g6g―40。

(4) Rotation direction code

Mark LH for left rotation and not for right rotation. For example, m10-7h-l-lh is a left-hand thread, and m10-7h-l is a right-hand thread.

2. Pipe Thread

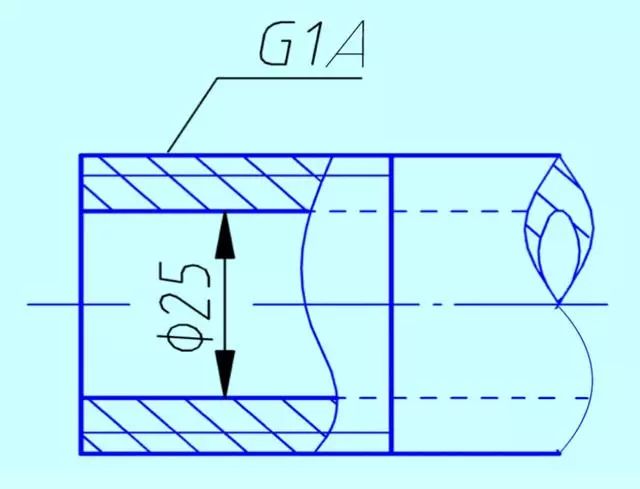

Pipe threads are generally used in the connection of pipelines (water pipes, oil pipes, gas pipes, etc.). The marking of pipe thread shall be marked with a guiding method, and the leader shall point to the major diameter of the thread.

Marking of pipe thread: it is composed of thread feature code, size code and direction of rotation. The size code (nominal diameter) of pipe thread is not the size of the major diameter of the thread, but the size of the drift diameter (inch system) of the pipe. The direction of rotation not noted in the mark is right-hand rotation.

(1) Marking of 55°unsealed pipe threads

G is the thread feature code of unsealed pipe thread, and the marking examples are as follows:

G3/4: single line right-hand cylindrical internal thread with size code of 3/4;

G3/4a or g3/4b: single line right-hand cylindrical external thread with size code of 3/4. A and B in the mark are the tolerance grade of thread pitch diameter;

G3/4lh and g3/4a-lh: LH refers to left-hand thread, and the thread pair formed by the two is only marked with the marking code of external thread.

(2) Marking of 55°sealing pipe thread

Characteristic code of 55 ° sealed pipe thread: sealed cylindrical internal thread RP, sealed conical internal thread RC, conical external thread R1 matched with cylindrical internal thread, and conical external thread R2 matched with conical internal thread. Examples of markings are as follows:

Rp3/4lh: single line left-hand cylindrical internal thread with size code of 3/4;

Rc3/4: single line right-hand conical internal thread with size code of 3/4;

Rp/r1 3/4 LH and rc/r2 3/4: internal thread and external thread are screwed together to form a thread pair.

3. trapezoidal thread and serrated thread

Trapezoidal thread and serrated thread are often used on the lead screw that transmits motion and power. When the trapezoidal thread works, both sides of the tooth are stressed, while the serrated thread works on one side. The marking of trapezoidal thread and serrated thread is similar to that of ordinary thread. The following is an example of marking for trapezoidal threads:

Tr40 × 7lh - 7e: trapezoidal thread (thread feature code: TR), nominal diameter φ 40, single line, pitch 7, left-hand rotation, pitch diameter tolerance zone code 7e, medium screwing length.

Note: only the code of pitch diameter tolerance zone is marked, and there are only two kinds of screw in length (code n and L). When the screw in length is equal, n is omitted and not noted.

When the thread is multi thread, it is marked as: tr40 × 14 (P7) – 7e, where “14” is the lead, “7” is the pitch, double thread.

The thread pair of trapezoidal thread is expressed as: tr40 × 7-7h/7c, the tolerance zone of internal thread is in the front, and the tolerance zone of external thread is in the back, and the two are separated by “/”.