As technology continues to advance, smart manufacturing is rapidly reshaping our world. In this transformation, custom precision parts machining is playing a pivotal role, shaping the future of the manufacturing industry. Precision parts machining stands as a crucial component within the realm of smart manufacturing, directly influencing the performance and lifespan of a wide array of products. This article delves into the profound impact of custom precision parts machining on the smart manufacturing sector and the transformative changes it brings about.

The Rise of Customized Manufacturing

Traditional manufacturing has historically focused on mass-producing standardized products. However, in recent times, an increasing number of businesses and consumers are seeking personalized, customized products. No longer constrained by the limitations of mass production, manufacturers and consumers alike are now exploring the boundless possibilities of customization. This trend is propelling the manufacturing industry towards a more flexible, efficient, and sustainable future, offering new avenues for innovation and entrepreneurship. This drive for customization encourages the industry to continuously seek innovation, with custom precision parts machining emerging as a key solution to meet these demands.

Intelligent Design and Processes

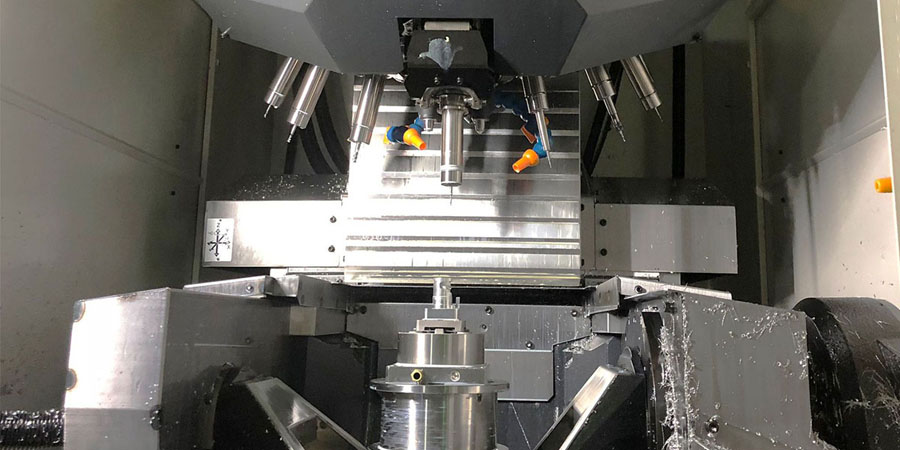

At the heart of smart manufacturing lies digital design and intelligent processes. Through Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems, manufacturers can rapidly design and fabricate precision parts according to specific customer requirements. These intelligent systems not only enhance the efficiency of design and manufacturing but also ensure the quality and precision of the parts.

Innovation in Materials and Processes

As scientific and technological advancements continue, the development of new materials and innovative manufacturing processes allows us to produce parts that are stronger, lighter, more heat-resistant, and corrosion-resistant. These innovations not only enhance the performance of parts but also reduce production costs, making custom precision parts more practical and feasible. Additionally, advanced machining processes such as laser cutting and electrical discharge machining enable manufacturers to precisely craft parts to meet highly individualized customer demands. This ongoing innovation in materials and processes is propelling the custom precision parts industry to higher levels of capability.

Efficiency and Sustainability

The manufacturing of customized precision parts plays a pivotal role in improving efficiency and sustainability. Through precise customization, we can reduce waste, lower energy consumption, and minimize material wastage to the greatest extent. This precision manufacturing process not only conserves resources but also reduces adverse environmental impacts, thereby enhancing sustainability. Moreover, the production of customized precision parts is typically more efficient, reducing unnecessary inventory and production cycles, further enhancing the efficiency of the manufacturing industry. Therefore, the manufacturing of customized precision parts has achieved remarkable accomplishments in the pursuit of efficiency and sustainability.

Future Outlook

With the rapid development of technologies such as artificial intelligence, big data analytics, and the Internet of Things, smart manufacturing is poised for greater opportunities. Customized precision parts machining will continue to play a significant role in the progress of smart manufacturing. This will bring about more efficient production, products that better meet customer demands, and a more sustainable manufacturing industry.

In summary, customized precision parts machining is at the forefront of the transformation of the smart manufacturing industry, redefining the future of manufacturing. With ongoing technological advancements, we can expect to see more innovations and opportunities, allowing the smart manufacturing industry to thrive and bring even greater benefits to society.