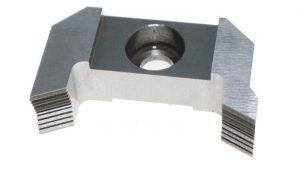

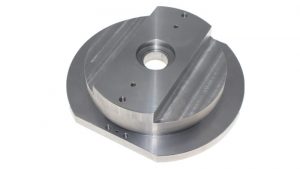

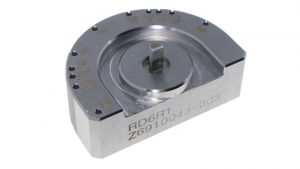

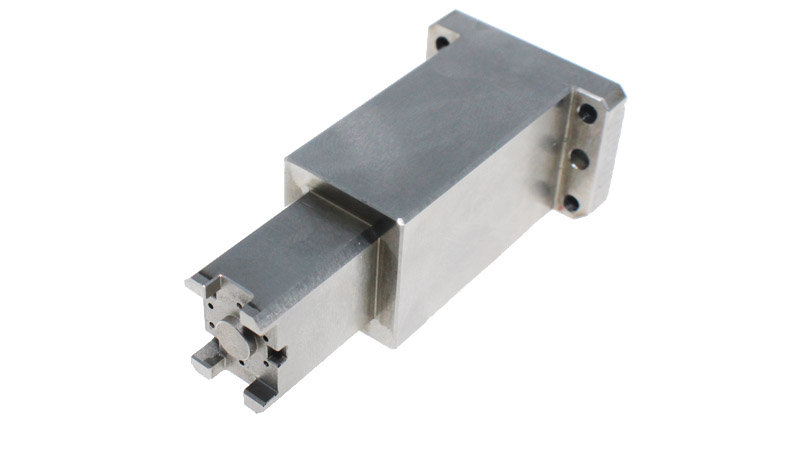

SKD11 Steel CNC Milling Parts

Specification

| Material | SKD11 Steel | |

| Specification | Size | 110*25*30mm |

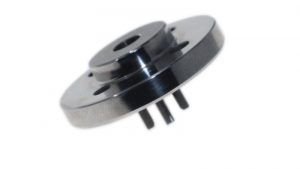

| Process | CNC Milling,Heat Treament, Grinding, EDM, Machinig Center | |

| Hoze Size | φ2 Hole, φ1 Hole, φ1.2Hole | |

| Angel | / | |

| Accuracy | ±0.01mm | |

| Tolerance | ±0.01mm | |

| Surface Finish | Standard | |

| Quality Assurance | 100% Inspection with Report, Material Report | |

| Advantages |

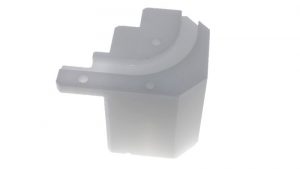

From the structural point of view, inserts are required for industrialization, and now they only make mold cores. Formwork outsourcing. In terms of materials, different parts may have different strength and temperature requirements, and the inserts can give full play to. In terms of technology, inserts bring convenience to metal processing, avoid complex processing, and can exhaust gas during injection molding. |

|

| Application | Widely used in electronics, automobiles, medical, home appliances, semiconductors and other product mold making. | |