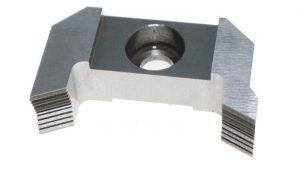

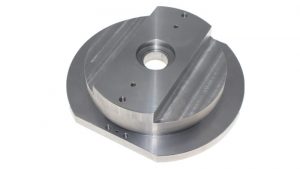

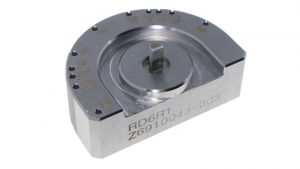

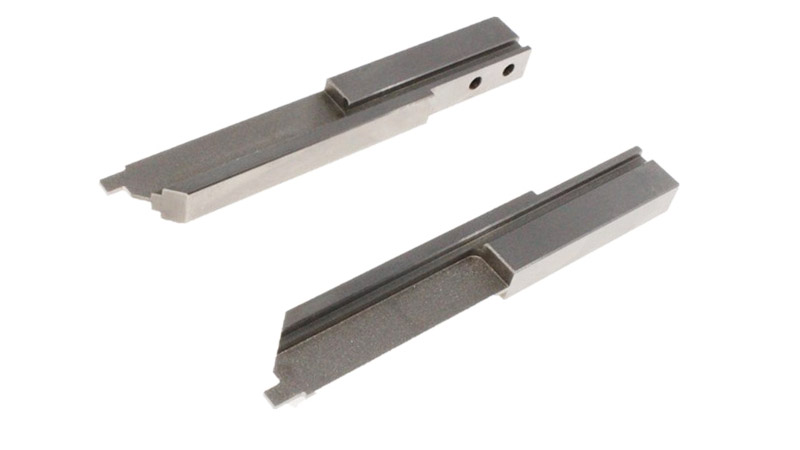

SKD11 Steel Precision Machining

Specification

| Material | SKD11 | |

| Specification | Size | 110*25*30mm |

| Process | CNC Milling, Grinding, Heating Treatment, EDM | |

| Hoze Size | M3 threaded hole | |

| Angel | / | |

| Accuracy | ±0.01mm | |

| Tolerance | / | |

| Surface Finish | Standard | |

| Quality Assurance | 100% Inspection with Report, Material Report | |

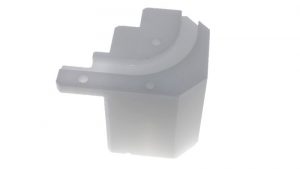

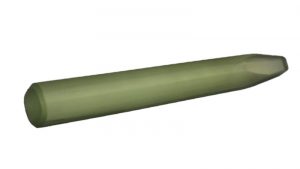

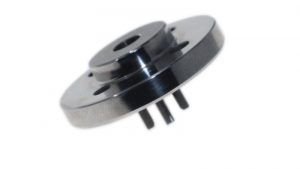

| Advantages | The push rods in the molds and fixtures are well designed to separate the molded products automatically or by handles. | |

| Application | Push rod processing is generally used in stamping molds, injection molds and special fixtures in the automotive and electronic industries. | |