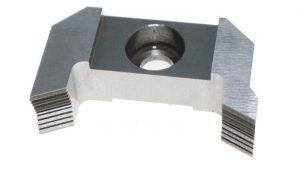

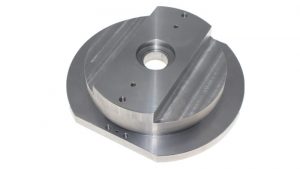

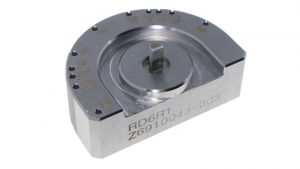

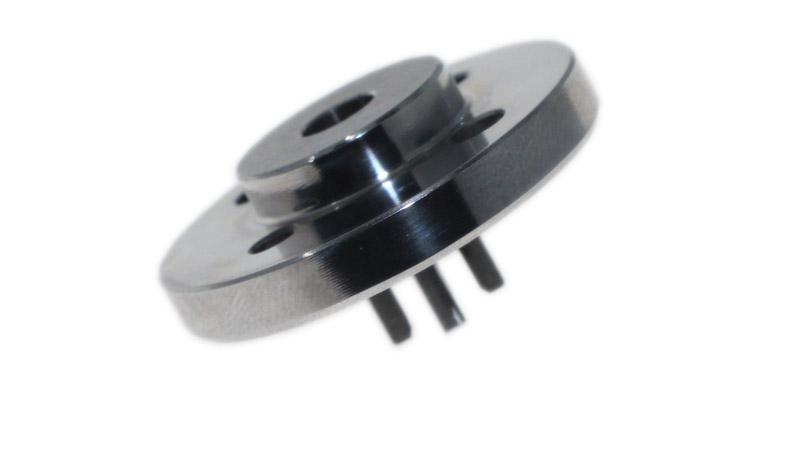

SKD11 Steel Turning Machined Part

Specification

| Material | SKD11 Steel | |

| Specification | Size | φ50 Round |

| Process | CNC Turning,Milling,OD Grinding, Machinig Center | |

| Hoze Size | φ8 Hole | |

| Angel | / | |

| Accuracy | ±0.01mm, precision hole H7 | |

| Tolerance | ±0.01mm, precision hole H7 | |

| Surface Finish | Anodizing | |

| Quality Assurance | 100% Inspection with Report, Material Report | |

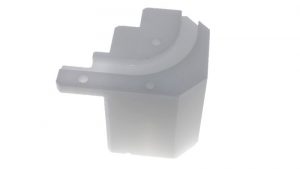

| Advantages | Precision motor winding parts processing can calculate the number of coils more accurately. The processing of multi-scale, high-strength, special-shaped and complex metal structural parts also puts forward high requirements. Therefore, the turning-milling composite processing technology plays an important role in the processing of micro-structures. | |

| Application | With the development of science and technology, the application of high-precision micro-small systems in aviation, aerospace, energy, weapons, medical equipment and other fields is becoming more and more extensive. | |