When it comes to materials in metalworking and manufacturing, understanding the differences between ferrous and non-ferrous metals is essential. Each type has distinct properties that make them suitable for various applications, influencing factors such as durability, corrosion resistance, weight, and cost. Here’s a detailed overview of the key characteristics, advantages, disadvantages, and common uses of ferrous and non-ferrous metals.

What Are Ferrous Metals?

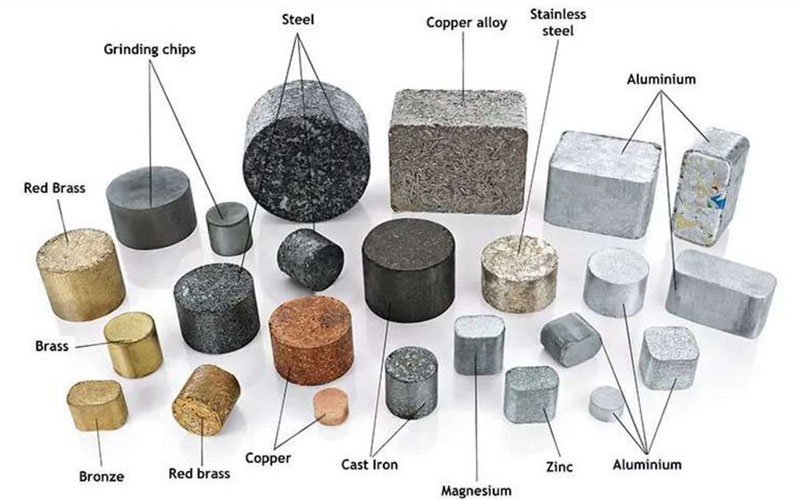

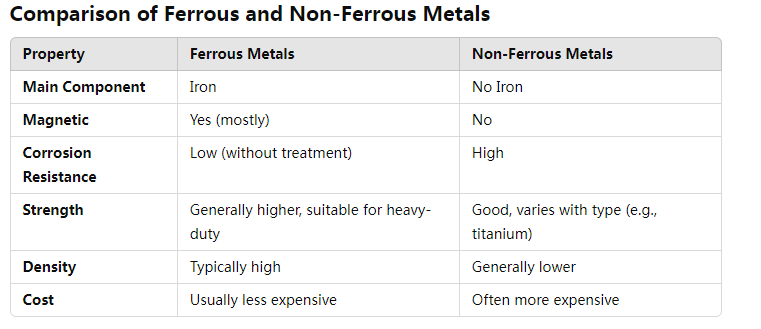

Ferrous metals contain iron as their primary component, which gives them their magnetic properties and typically high tensile strength. Common examples of ferrous metals include steel, cast iron, and wrought iron.

Characteristics of Ferrous Metals:

Magnetic Properties:

Most ferrous metals are magnetic, making them suitable for applications like motors and electrical appliances.

High Tensile Strength:

Ferrous metals are known for their strength and durability, which makes them ideal for construction and heavy-duty manufacturing.

Prone to Rust:

Unless specifically treated or alloyed (e.g., stainless steel), ferrous metals are susceptible to rust and corrosion due to their iron content. To prevent this, ferrous metals often undergo protective treatments, such as galvanizing or painting, to enhance their resistance to environmental factors.

Relatively Heavy:

Ferrous metals tend to be dense, adding weight to the structures or components they are used in.

In addition to their mechanical properties, ferrous metals are also valued for their recyclability, which supports sustainable practices in industries that consume large quantities of raw materials. The combination of strength, magnetic properties, and recyclability makes ferrous metals worthwhile in various technological and industrial advancements.

Common Uses of Ferrous Metals:

Construction

Ferrous metals, especially steel, plays a crucial role in the construction industry. Due to its high tensile strength and ability to withstand heavy loads, steel is widely used in building structures, including skyscrapers, bridges, and residential buildings. Reinforced concrete combines concrete and steel bars, and is also a standard material for building durable and resilient infrastructure.

automotive industry

The automotive industry heavily relies on ferrous metals to manufacture various components. Due to its durability and impact resistance, steel is used in the production of car frames, body panels, and engine components. Cast iron is commonly used in engine cylinder blocks, brake rotors, and suspension components to provide the necessary strength and wear resistance for these critical components.

Manufacturing and Machinery

Ferrous metals is an essential material for manufacturing tools, machinery, and industrial equipment. Tool steel is known for its hardness and wear resistance, and is used to manufacture cutting tools, molds, and dies. The durability and strength of Ferrous metals make it an ideal choice for heavy machinery and equipment used in mining, agriculture, and manufacturing industries.

What Are Non-Ferrous Metals?

Non-ferrous metals do not contain iron and therefore are not magnetic. They are often chosen for applications requiring lighter weight, higher conductivity, or resistance to rust and corrosion. Examples include aluminum, copper, brass, and zinc.

Characteristics of Non-Ferrous Metals:

Non-Magnetic:

Most non-ferrous metals do not have magnetic properties, making them ideal for electronic and electrical applications.

Corrosion Resistance:

Non-ferrous metals are generally more resistant to rust and corrosion, which makes them suitable for outdoor and marine applications.

Lightweight:

Many non-ferrous metals, such as aluminum and titanium, offer high strength-to-weight ratios. For instance, aluminum is extensively used in the aerospace and transportation industries due to its lightweight and high strength-to-weight ratio.

High Conductivity:

Metals like copper and aluminum are excellent conductors of electricity and heat. Copper, known for its excellent electrical conductivity, is a critical material in electrical wiring and electronic components.

recyclability

Another significant advantage of non-ferrous metals is their recyclability. Metals like aluminum and copper can be recycled repeatedly without losing their properties, supporting sustainable practices and reducing environmental impact.

Common Uses of Non-Ferrous Metals:

Aerospace industry

The aerospace industry heavily relies on non-ferrous metals such as aluminum and titanium. Aluminum is lightweight and high-strength, making it an ideal material for aircraft structures that can reduce overall weight and improve fuel efficiency. Titanium is used in jet engines, landing gear, and fuselage components due to its excellent strength, corrosion resistance, and ability to withstand extreme temperatures.

Electrical and Electronic

Nonferrous metals, especially copper, are crucial in the electrical and electronic industries. The excellent conductivity of copper makes it the preferred material for wires, circuit boards, and connectors. In addition, aluminum is also used for power transmission lines. Meanwhile, precious metals such as gold and silver are used in high-performance electronic components and connectors due to their excellent conductivity and corrosion resistance.

Piping and HVAC systems

Nonferrous metals such as copper and aluminum are widely used in pipelines and HVAC systems (heating, ventilation, and air conditioning). Copper pipes and fittings are favored for their durability, corrosion resistance, and antibacterial properties, making them ideal choices for drinking water systems. Aluminum is used in components such as heat exchangers and air conditioning coils in HVAC systems due to its thermal conductivity and lightweight properties.

Consumer goods and jewelry

Nonferrous metals are widely used in the production of consumer goods and jewelry. Due to its non reactive and lightweight properties, aluminum is used to manufacture household items such as cookware, cans, and packaging. Precious metals such as gold and silver are highly regarded for their ability to create exquisite jewelry and decorations. These metals are also used in coins and collectibles, utilizing their beauty and durability.

Advantages and Disadvantages

Advantages of Ferrous Metals:

High strength and durability make them ideal for construction and industrial uses.

Generally more affordable due to the abundance of iron.

Disadvantages of Ferrous Metals:

Prone to rust and corrosion unless adequately treated.

Heavier, which can be a disadvantage in applications where weight is a concern.

Advantages of Non-Ferrous Metals:

Resistant to rust and corrosion.

Lightweight with good strength-to-weight ratio.

High conductivity for electrical and thermal applications.

Disadvantages of Non-Ferrous Metals:

Often more expensive than ferrous metals.

Generally lower tensile strength compared to ferrous metals (with some exceptions).

Choosing Between Ferrous and Non-Ferrous Metals

The choice between ferrous and non-ferrous metals depends on the specific requirements of your application, such as strength, weight, corrosion resistance, and conductivity. Understanding their unique properties and uses can help make informed decisions to achieve optimal performance and durability. These two metals play a crucial role in various industries, ensuring technological and industrial progress.

Understanding the key differences and applications of ferrous and non-ferrous metals allows engineers and manufacturers to make informed decisions, ensuring the right material is used for the right application, ultimately improving performance, longevity, and cost-effectiveness.