The correct custom CNC machining depends to a large extent on the entire process. This is where the jig and fixture work. Custom CNC parts are usually used with them. This is because these parts have special functions. In some cases, special features may cause the price of machined parts to rise significantly. A good way to solve this problem is to use jigs and fixtures correctly in custom CNC machining.

This article will introduce CNC workpiece fixtures in three steps. It will show its functions and applications. It will provide reliable information about the types of CNC fixtures. Finally, it will provide you with the best information on how to get the best CNC fixture design or use custom CNC fixtures.

What Are Jigs And Fixtures?

Jigs and fixtures are production equipment used to accurately manufacture parts according to specified requirements, especially for customized parts. The range of jigs and fixtures in processing may include bushings, sleeves, masks, parts fixing brackets, position fixers, etc.

It is a work clamping device with a wide range of uses. It is mainly used to correctly fix, support or install workpieces on CNC machine tools.

CNC fixtures are important tools to ensure consistency and interchangeability in the manufacturing process. With this, many will compare them to jigs. However, they are different. A jig works to guide the cutter’s movement. However, CNC workholding fixtures do not guide cutters. They only secure, support, and stabilize the workpiece during the manufacturing process.

The Role Of Jigs And Fixtures In Custom CNC Machining

Some professionals come with the correct choice of fixtures. One key is to reduce the cost of the CNC machining process. It achieves this goal by achieving smooth operations, simplifying production, and speeding up the transition.

Carefully selected jigs and fixtures will allow smooth operation, simplified production and rapid process conversion, thereby significantly improving the economics of the manufacturing process. Tools and fixtures help to compensate for the limitations of CNC machine when machining parts. They are designed to provide safe installation and maintain the reliability of the position of the part during processing. The following describes the different functions of jigs and fixtures in custom machining:

Part Holding

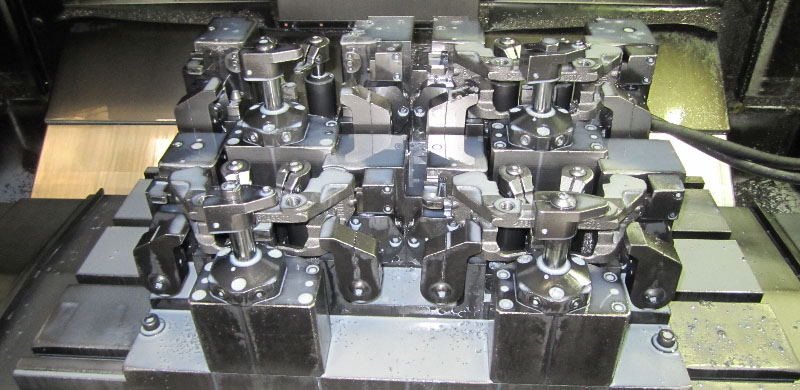

Jigs and fixtures are mainly used to fix parts in place during processing. We custom-designed it to fit the unique parts being CNC machined. Therefore, regardless of the shape, they hold the part at any unique angle. Reliable custom fixtures are essential to prevent chattering and possible errors when the tool is pulled out. Some examples of fixing devices that provide part fixing are: chuck, vise, center, fixing plate and milling fixing device.

Parts Protection

Jigs and fixtures can also protect parts during custom CNC machining. Therefore, they help maintain the required surface finish and maintain proper runout.

Sleeves, bushings and mask fixtures are usually designed to control the surface finish of custom parts. This is done to protect the surface of the finished part from metal chips/chips, thereby preventing the workpiece from being subjected to different machining processes. In addition, the customized machining center has been specially designed to meet the requirements of customized parts with tight labeling of overall runout.

Location Control

Jigs and fixtures are very important for maintaining dimensional and positional accuracy. They ensure that the workpiece is held in the correct position and orientation during processing. For these reasons, it makes the fixture an easy way to incorporate fool-proof protection in the process to minimize errors caused by human factors.

The fixing device controls the position, direction and stability by limiting the degree of freedom of the workpiece. This is done by using pins, clamps, planes and fasteners when designing the required fixtures. The plane provides support for the parts. At the same time, the clamp is allowed to move during installation and can also be used during disassembly. Finally, pins provide precise position control for unique functions.

In custom parts processing, due to specific installation restrictions, features such as holes and slots are controlled in specific locations that may be difficult to machine. This is the reason for designing fixtures. Fixtures are the most reliable method for machining difficult part features.

Part Consistency

The fixture allows us to machine multiple custom parts while still maintaining its top-notch quality. They ensure that each part maintains a consistent quality. The fixture can process multiple customized parts while ensuring quality. They ensure that the quality between the parts is consistent. Functional controls that require consistency, including flatness, parallelism, and perpendicularity.

Reduce Settings

Fixtures are a good way to eliminate the tedious inspection process during part loading. By designing fixtures for custom parts, the entire process can be plug-and-play. Our operators only need to load the workpiece. This is because the fixture has managed part reference and position control. This helps greatly reduce the setup time that we can use in other value-added processes. One fixture that ideally helps us reduce preparation time is the change of molds every minute. Some examples of fixtures that reduce setup time are SMED (One-Minute Replacement of Molds) fixtures, milling fixtures, soft jaws, hexagonal milling fixtures, and so on.

Types of CNC Fixture

Most people are not familiar with the classification of CNC fixtures. No need to worry. This section will introduce you the types of CNC fixtures from different angles.

Based On CNC Machining Operations

When classifying according to CNC operation, there are five types of CNC jigs. The following are some introductions about CNC fixtures.

Turning Fixture

CNC turning is a CNC machining operation in which a part of the workpiece is removed when it rotates on a single axis. Turning fixtures are CNC fixtures used in this process.

Milling Fixture

CNC milling is just a cutting CNC machining process. During this process, the computer instructs the cutting machine to cut off the required part of the workpiece. The milling fixture is the CNC fixture used in this process.

Drilling Fixture

Drilling is a popular process in the manufacturing process, and it is more popular in CNC machining. This means punching holes in the workpiece. The CNC fixture used in CNC drilling is called CNC drilling fixture.

Boring Fixture

CNC boring is a CNC machining process in which a tool is used to enlarge a hole that has been drilled using CNC drilling. The fixture used in this process is a CNC boring fixture.

Grinding Fixture

CNC grinding involves removing part of the workpiece with the aid of a grinder. This is another popular CNC machining process used for cutting CNC milling. Grinding fixture is a fixture suitable for CNC grinding process.

Generally, you can draw valuable conclusions about CNC fixtures based on CNC machining operations. Each CNC machining operation that requires a fixture has the name of the operation. Therefore, you can use other tools such as CNC honing jigs and CNC grinding jigs.

According To The Purpose

You can classify CNC fixtures according to their use. There are five types of CNC clamps in this category. Here are some introductions to these five aspects.

General Fixture

General CNC fixtures can be used on any workpiece, and they can be easily adjusted. Each part of the fixture is adjustable and can be replaced to fit any workpiece. Just like its name, universal lamps have a very wide range of applications.

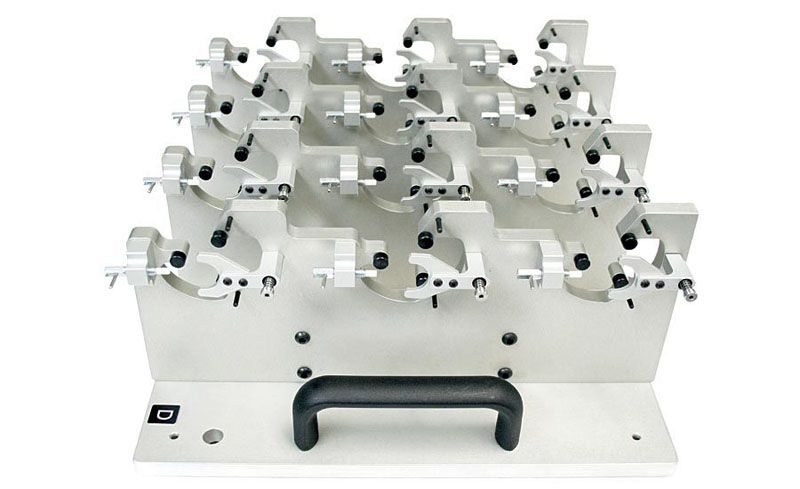

Special Fixtures

Special fixtures are CNC fixtures, which are very suitable for specific workpieces. When used with this particular workpiece, they provide advantages in terms of stability. It also has faster operation and convenience during use.

Assembly Fixture

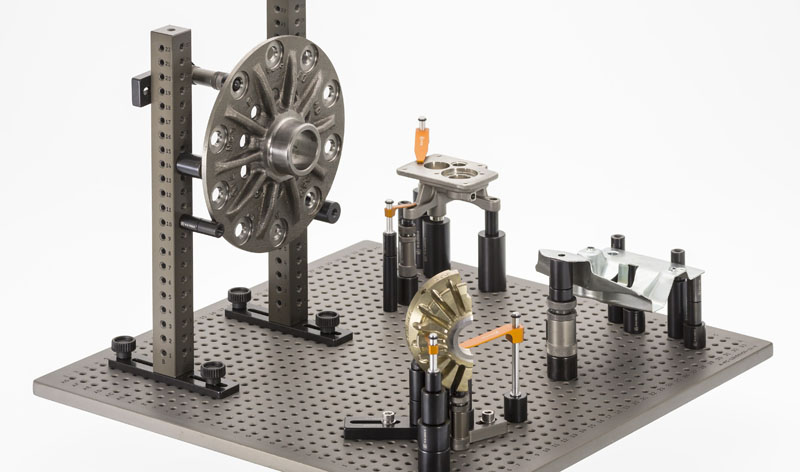

The assembled CNC fixture can only appear after considering the workpiece. Fixtures are determined according to the requirements of such workpieces. The assembly is carried out by a special method. According to your needs, you can delete or reuse it when necessary.

Modular Fixture

Modular fixture is a fixture that is easy to reconfigure and reconfigure to fit any workpiece. They come from interchangeable components and are ideal for handling many workpieces. After completing the process, you can also remove the fixture. Modular fixtures provide a better and more flexible manufacturing process.

Combination Fixture

The combined fixing device has different sizes and shapes. They are ideal for processing many different sizes and shapes of workpieces based on machine tools.

According To Its Power

This is the final classification process and is based on the power supply of the CNC fixture. The following are six types of CNC fixtures based on power supplies.

Manual Fixture.

Pneumatic Fixture.

Hydraulic Fixture.

Electric Fixture.

Magnetic Fixture.

Vacuum Fixture.

What To Know When You Want To Design Or Use CNC Fixtures

There are many things to know to use CNC fixtures or to understand the correct CNC fixture design. The following is some information to know whether you already have a CNC fixture platform or need a custom CNC fixture.

Increase Tolerance

CNC tooling and fixtures help you increase the tolerance of your manufacturing operations. Therefore, it is important to ensure that its settings improve accuracy.

Know When To Clamp

The clamping method has a huge impact on product quality. Although you may think that the best way is to clamp the workpiece well, don’t do this.

Reference Important Surface

If you want to shorten the operating time, you may need to refer to important workpieces on the tool. However, many surfaces should not be quoted to avoid confusion.

Be Economical

Another important consideration when designing custom CNC fixtures is economy. You need to know the number of parts to be manufactured and the number of fixtures required.