The milling cutter is generally a multi-edged tool. Due to the large number of teeth participating in the cutting at the same time, the long cutting edge, and the higher cutting speed, the productivity is high. The application of different milling cutters can process planes, grooves, steps, etc., and can also process gears, threads, spline shaft tooth profiles and various forming surfaces.

Types And Uses Of Milling Cutters

The types of milling cutters can be divided into sharp tooth milling cutters and relief tooth milling cutters according to the tooth structure. According to the relative position of the tooth and the axis of the milling cutter, it can be divided into cylindrical milling cutter, angle milling cutter, face milling cutter, forming milling cutter, etc. According to the tooth shape, it can be divided into straight tooth milling cutter, helical tooth milling cutter, angular tooth milling cutter and curve tooth milling cutter. According to the tool structure, it can be divided into integral milling cutter, combined milling cutter, group or complete set of milling cutter, insert milling cutter, machine clamp welding milling cutter, indexable milling cutter, etc. But it is usually divided into the form of cutting tool tooth back processing.

Sharp Tooth Milling Cutters can be divided into the following categories:

(1) Face milling cutter: There are integral face milling cutter, tooth face milling cutter, machine clamp indexable face milling cutter, etc., which are used for rough, semi-precision and finishing of various planes and step surfaces.

(2) End mill: used for milling steps, sides, grooves, holes of various shapes on the workpiece, and inner and outer curved surfaces.

(3) Keyway milling cutter: used for milling keyway, etc.

(4) Slot milling cutter and saw blade milling cutter: used for milling various grooves, sides, step surfaces and sawing.

(5) Special slot milling cutter: used for milling various special groove shapes, shaped slot milling cutter, half-moon keyway milling cutter, dovetail milling cutter, etc.

(6) Angle milling cutter: used for straight grooves and spiral grooves of milling tools.

(7) Mold milling cutter: used for milling the convex and concave forming surfaces of various molds.

(8) Group milling cutter: Combine several milling cutters into a group of milling cutters, which are used for milling complex forming surfaces, surfaces of different parts of large parts, and wide planes.

Relief Tooth Milling Cutters:

Some milling cutters that require regrinding the front face to maintain the original section shape, and their back face uses relief tooth form, including disc slot milling cutters, convex semicircular, concave semicircular milling cutters, double-angle milling cutters, and forming milling cutters Knife etc.

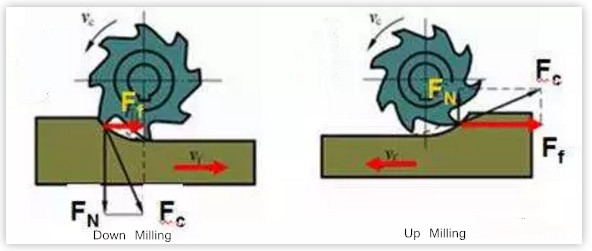

Down Milling And Up Milling

There are two ways relative to the feed direction of the workpiece and the direction of rotation of the milling cutter:

There are two ways relative to the feed direction of the workpiece and the direction of rotation of the milling cutter:

The first type is down milling. The rotation direction of the milling cutter is the same as the cutting feed direction. When the cutting starts, the milling cutter bites the workpiece and cuts off the final chips.

The second type is up-milling. The rotation direction of the milling cutter and the cutting feed direction are opposite. The milling cutter must slide on the workpiece for a period of time before starting to cut, starting with the cutting thickness as zero, and reaching the cutting thickness at the end of the cutting maximum.

How to Choose

In the face milling cutter, some end milling or face milling, the cutting force has different directions. When face milling, the milling cutter is just on the outside of the workpiece, and special attention should be paid to the direction of the cutting force. During down milling, the cutting force presses the work piece against the worktable, and during up milling, the cutting force pushes the work piece away from the worktable.

The power consumption of down milling is smaller than that of up milling. Under the same cutting conditions, the power consumption of down milling is 5% to 15% lower. At the same time, down milling is also more conducive to chip removal.

Generally, down milling should be used as much as possible to improve the surface finish (reduce roughness) of the processed parts and ensure dimensional accuracy. However, when there is a hard layer, slag accumulation on the cutting surface, and the surface of the workpiece is more uneven, such as processing a forging blank, the up-milling method should be used.

When down milling, the cutting thickness becomes thinner, and the cutter teeth cut into the unmachined surface, which is beneficial to the use of the milling cutter.

In up-milling, when the cutter teeth of the milling cutter contact the workpiece, they cannot cut into the metal layer immediately, but slide a short distance on the surface of the workpiece. During the sliding process, due to strong friction, a large amount of heat will be generated, and at the same time, the surface to be processed It is easy to form a hardened layer, which reduces the durability of the tool, affects the surface finish of the workpiece, and brings disadvantages to cutting.

In addition, during up-milling, because the cutter teeth cut from bottom to top (or from the inside to the outside) and cut in from the hard surface layer, the cutter teeth are subjected to a great impact load, and the milling cutter becomes dull faster, but the cutter teeth cut in There is no slippage in the process, and the worktable will not move during cutting.

Up-milling and down-milling, because the cutting thickness when cutting into the workpiece is different, the contact length of the tooth and the workpiece is different, so the degree of wear of the milling cutter is different. Practice shows that the durability of the milling cutter is 2 to 3 times higher than that of the up-milling. , The surface roughness can also be reduced. However, down milling is not suitable for milling hard-skinned workpieces.