In machining, the choice of tools is a technology. We know that the cutting performance of the tool often depends on the material of the cutting part of the tool, the tool structure and the geometric material of the tool. What affects the tool life, processing efficiency, processing quality and processing cost is the material of the tool itself and the material of the workpiece processed by the tool.

Therefore, in machining, selecting suitable tools for machining parts of different materials not only improves machining efficiency and machining quality, but also extends tool life and reduces machining costs.

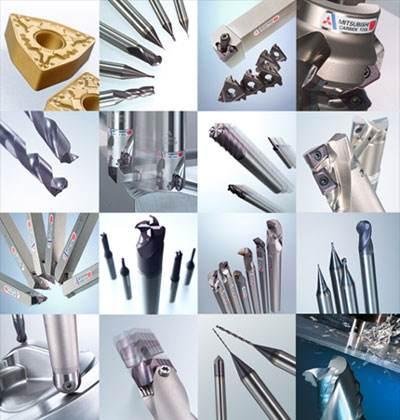

At present, there are six main materials for machining tools: diamond tools, PCBN tools, ceramic tools, coated tools, carbide tools, and high-speed steel tools. Let’s take a look at what kind of materials these six tools are suitable for machining parts.

Diamond Tool

Diamond tools are divided into: natural diamond tools, PCD diamond tools, and CVD diamond tools.

Diamond tools are mostly used for fine cutting and boring of non-ferrous metals and non-metal materials at high speeds. Suitable for processing various wear-resistant non-metals and various wear-resistant non-ferrous metals. The disadvantage of diamond tools is poor thermal stability. When the cutting temperature exceeds 700℃~800℃, its hardness will be completely lost. In addition, it is not suitable for cutting ferrous metals, because diamond (carbon) easily interacts with iron atoms at high temperatures, transforming carbon atoms into graphite structures, and the tool is easily damaged.

PCBN Tool

PCBN tools can be divided into integral PCBN blades and PCBN composite blades sintered with cemented carbide.

PCBN tools are suitable for finishing various hard-to-cut materials such as hardened steel, hard cast iron, high-temperature alloys, hard alloys, and surface spray materials. The machining accuracy can reach IT5 (hole is IT6), and the surface roughness value can be as small as Ra1.25~0.20m. PCBN tools have poor toughness and bending strength. Therefore, cubic boron nitride turning tools are not suitable for rough machining at low speeds and large impact loads. At the same time, they are not suitable for cutting materials with high plasticity (such as aluminum alloys, copper alloys, nickel-based alloys, steel with high plasticity, etc.). Because cutting these metals will produce serious built-up edge, which will deteriorate the machined surface.

Ceramic Tool

Ceramic tool materials can generally be divided into three categories: alumina-based ceramics, silicon nitride-based ceramics, and composite silicon nitride-alumina-based ceramics.

Ceramics is one of the tool materials mainly used for high-speed finishing and semi-finishing. Ceramic tools are suitable for cutting all kinds of cast iron (gray cast iron, ductile iron, malleable cast iron, chilled cast iron, high-alloy wear-resistant cast iron) and steel (carbon structural steel, alloy structural steel, high-strength steel, high-manganese steel, quenched steel) Etc.), can also be used to cut copper alloys, graphite, engineering plastics and composite materials. Ceramic tool materials have the problems of low bending strength and poor impact toughness. They are not suitable for cutting at low speeds and impact loads.

Coated Tool

According to different coating methods, it can be divided into chemical vapor deposition (CVD) coated tools and physical vapor deposition (PVD) coated tools. According to the different substrate materials, it can be divided into hard alloy coated tools, high speed steel coated tools, and coated tools on ceramic and superhard materials. According to the nature of the material, it can be divided into hard-coated tools and soft-coated tools. There are also popular nano-coated tools.

Coated tools have great potential in the field of CNC machining and will be the most important tool variety in the field of CNC machining in the future. Coating technology has been applied to end mills, reamers, drills, composite hole machining tools, gear hobs, gear shapers, gear shaving cutters, forming broaches and various machine-clamped indexable inserts to meet the requirements of high-speed cutting The need for materials such as steel and cast iron, heat-resistant alloys and non-ferrous metals. As the coating thickness increases, the tool life will increase, but when the coating thickness reaches saturation, the tool life will no longer increase significantly. When the coating is too thick, it is easy to cause peeling, and when the coating is too thin, the wear resistance is poor.

Carbide Tool

According to the main chemical composition, cemented carbide can be divided into tungsten carbide-based cemented carbide and titanium carbon (nitride) (TiC(N))-based cemented carbide. Among them, tungsten carbide-based cemented carbides include tungsten-cobalt (YG), tungsten-cobalt-titanium (YT), and rare carbide-added (YW). They have their own advantages and disadvantages. The main components are tungsten carbide (WC) and carbide Titanium (TiC), tantalum carbide (TaC), niobium carbide (NbC), etc.

YG alloys are mainly used for processing cast iron, non-ferrous metals and non-metallic materials. Fine-grained cemented carbide (such as YG3X, YG6X) has higher hardness and wear resistance than medium-grain when the cobalt content is the same. It is suitable for processing some special hard cast iron, austenitic stainless steel, heat-resistant alloy, Titanium alloy, hard bronze and wear-resistant insulating materials, etc. The outstanding advantages of YT cemented carbide are high hardness, good heat resistance, higher hardness and compressive strength at high temperature than YG, and better oxidation resistance. YW alloys have both the properties of YG and YT alloys with good overall performance.

High-speed Steel Tool

According to different purposes, high-speed steel can be divided into general high-speed steel and high-performance high-speed steel. General-purpose high-speed steel can generally be divided into two types: tungsten steel and tungsten-molybdenum steel. High-performance high-speed steel mainly includes the following categories: high-carbon high-speed steel, high-vanadium high-speed steel, cobalt high-speed steel, aluminum high-speed steel, nitrogen super-hard high-speed steel.

General-purpose high-speed steel: mainly used to manufacture cutting tools (such as drills, taps, saw blades) and precision tools (such as hobs, gear shapers, and broaches) for metal materials with a cutting hardness of HB≤300. The commonly used steel grades are W18Cr4V , W6Mo5Cr4V2, etc.

Special purpose high-speed steel: Including cobalt high-speed steel and super-hard high-speed steel (hardness HRC68~70), mainly used to make tools for cutting difficult-to-machine metals (such as high-temperature alloys, titanium alloys and high-strength steels). Commonly used steel grades are W12Cr4V5Co5, W2Mo9Cr4VCo8, etc.