When it comes to CNC machining, the reliability and consistency of quality are paramount. Selecting the right CNC machining provider involves a thorough evaluation process to guarantee that your precision parts meet stringent standards consistently. Here’s a guide on how to ensure consistent quality from a CNC machining provider:

Supplier Evaluation And Selection:

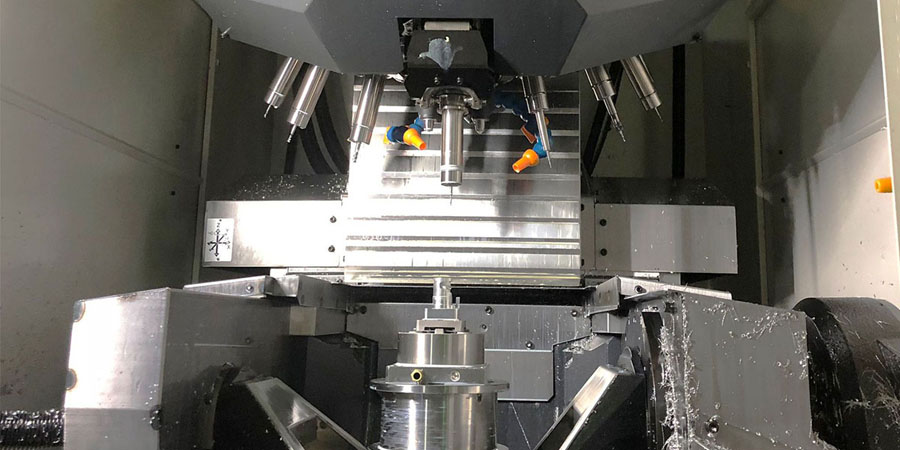

Evaluate suppliers, including their processing capabilities, equipment, technical level, quality management, and other aspects. Choose suppliers with good reputation and stable quality, and establish long-term cooperative relationships with them.

Also can seek recommendations from industry peers, explore online reviews, and ask the provider for references. A solid reputation is indicative of reliability.

Clarify Quality Standards And Requirements:

Clarify quality standards and requirements with suppliers, including machining accuracy, surface quality, dimensions, etc. Ensure that suppliers understand and comply with these requirements, and clearly specify quality standards and acceptance methods in the contract.

Stringent quality control measures are necessary at every stage of machining. Inquire about the provider’s quality control protocols. This includes inspection processes, testing, and documentation of quality metrics.

Quality Inspection And Acceptance:

A robust quality management system is essential for consistent precision. Require suppliers to conduct quality testing on finished products, including dimensional testing, surface quality testing, etc. During acceptance, it is necessary to verify whether the product quality meets the requirements, and trace and handle non-conforming products.

Material Expertise:

Ensure the provider has experience with the materials relevant to your project. This includes knowledge of material properties and how they impact machining.

By understanding customer needs and material characteristics, we can better provide customized services to our customers. For example, for parts that require urgent processing, it is possible to quickly respond and meet customer needs by understanding the processing characteristics of the material and the special requirements of the customer.

Capacity For Customization:

A provider capable of tailoring solutions to your specific needs is advantageous.

Assess the provider’s flexibility in handling custom projects. This includes their willingness to adapt processes to meet your unique requirements.

By customizing the processing of non-standard precision parts, we can provide customers with innovative products and services, help them solve complex problems, and enhance their competitiveness.

Communication And Transparency:

Clear communication is crucial for project success. Evaluate the provider’s communication channels and transparency in sharing project progress. Regular updates and openness contribute to a collaborative partnership.

Continuous Improvement And Training:

Establish good communication channels with suppliers and encourage them to provide improvement suggestions and suggestions. At the same time, provide training and support to help suppliers improve their quality management level and technical capabilities.

Regular Audits And Inspections:

Regularly audit and inspect suppliers to ensure the effectiveness and implementation of their quality management system. At the same time, statistics and analysis of supplier quality data are conducted to timely identify problems and take improvement measures.

Establishing Long-term Cooperative Relationships:

Establish long-term cooperative relationships with suppliers, jointly develop and implement quality management plans, and ensure that suppliers always provide consistent quality levels. Meanwhile, by collaborating with suppliers, technology and resource sharing can be achieved, enhancing the competitiveness of the entire supply chain.

In conclusion, ensuring consistent quality from a CNC machining provider involves a meticulous assessment of their reputation, processes, capabilities, and commitment to excellence. By choosing a provider with a track record of reliability, a comprehensive quality management system, and a commitment to technological advancement, you set the stage for a successful and enduring partnership that delivers precision parts of the highest quality.