At present, almost most customized CNC machining parts will produce more or less burrs after processing. They not only affect the beauty of the parts, but also fail to meet high-precision standards, and even affect the assembly, performance and life of the product. So we must remove them in order to provide better products to our global customers. With the development of high technology and the improvement of product performance, the requirements for product quality are becoming more and more stringent. The burr removal of precision machined parts has become More important.

Today we will introduce what is a burr, and summarize the common methods of removing burrs for precision machined parts.

What Is Burrs?

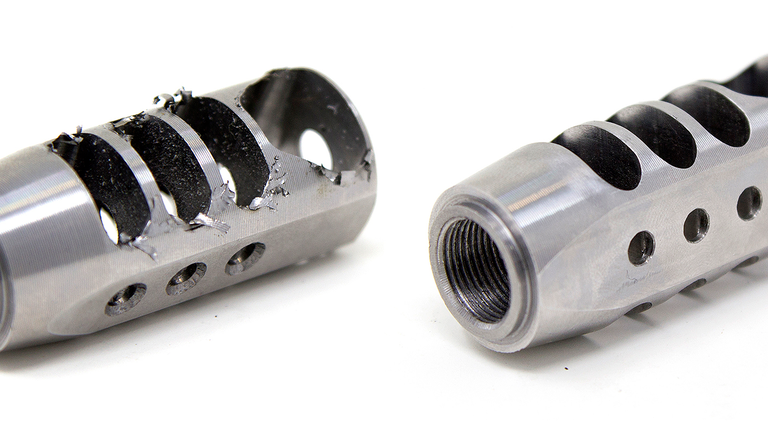

Before we dive into the details of the deburring process, it is important to understand what a burr is and how it affects the quality of metal parts. Manufacturers use various operations to turn metal blanks into usable parts: such as stamping, milling, grinding, cutting, and engraving. As you know, these methods usually leave rough edges or material protrusions on the seams and edges of metal parts. Rough edges are defects called burrs, and the process of removing them is called deburring.

In addition to being unsightly, metal burrs can also have a negative impact on the safety, functionality and overall quality of the parts:

Small gaps can cause moving parts to jam, increasing the chance of accidents or unnecessary production delays.

The sharp edges pose a safety hazard to the workers and final consumers who handle the parts.

The presence of burrs can interfere with the application of other finishing processes, such as powder coating and electroplating.

If ignored, metal burrs can cause potentially costly problems for manufacturers.

Metal deburring is essential to ensure the quality and function of metal parts.

Tools And Methods For Removing Burrs

Die Deburring

The burrs are removed by making punch. It is necessary to make rough die and fine blanking for stamping burrs, and it may be necessary to make the sizing die. For products with a simple parting surface, the efficiency and effect of deburring are better than manual methods.

Manual Deburring

The operator uses files, sandpaper, grinding heads and other tools to polish the workpiece to remove burrs. This method does not have very high technical requirements for workers. It is suitable for products with small burrs and simple product structure. Therefore, it is also a deburring method commonly used by general enterprises. There are two types of sickles: manual files and pneumatic files. Manual files are more expensive, the deburring efficiency is not very high, and complex cross holes are difficult to remove. The technical requirements for workers are not very high, and it is suitable for products with small burrs and simple product structure.

Manual deburring is flexible and cost-effective, but requires a lot of time investment, so it is not suitable for finishing a large number of parts.

Frozen Deburring

This is a way to make the burr brittle and remove the burr by suddenly cooling down. Frozen deburring is suitable for products with small burr walls and small workpieces. The whole set of equipment is expensive, about 2.3 million yuan.

Hot Deburring

Deburring by thermal blasting is also called thermal deburring and blasting. Put some combustible gas into the furnace, then use some media and conditions to make the gas explode instantly, and use the energy generated by the explosion to remove burrs. The equipment required for this method is expensive, usually more than one million, and the requirements for operation technology are very strict. The efficiency of removing burrs is low, and side effects such as rust and deformation will occur. Thermal explosion deburring is mainly used for some high-precision parts, such as precision parts such as automobiles and aerospace.

Engraving Machine To Remove Burrs

The price of the equipment required by the engraving machine to remove the burrs on the workpiece is not very expensive, usually only tens of thousands of yuan. It is suitable for removing simple burrs with regular space and simple structure.

Chemical Deburring

Chemical deburring is a process of automatically and selectively removing burrs on metal parts using electrochemical reactions. Suitable for internal burrs that are difficult to remove. It is especially suitable for removing small burrs on the pump body and valve body.

Electrolytic Deburring

This method uses electrolysis to remove burrs on metal parts. This method has certain side effects, because the electrolyte is corrosive, and the surface near the burr will also be affected by the electrolysis. The surface will lose its luster and even affect its dimensional accuracy. Therefore, the workpiece after deburring should be cleaned and derusted. This method is suitable for removing complex burrs in the cross holes of the concealed parts. Its production efficiency is high, and a single operation usually only takes a few seconds to tens of seconds. Suitable for deburring of gears, connecting rods, valve bodies, crankshaft oil passage ports and sharp corners.

Use High-pressure Water Jet To Remove Burrs

This uses the instantaneous impact of water to remove burrs while maintaining cleanliness. This set of equipment is expensive and is mainly used in the heart of automobiles and hydraulic control systems of construction machinery.

Ultrasonic Deburring

The propagation of ultrasonic waves can also generate instantaneous high pressure and remove burrs on parts. This method has high precision and is mainly used to remove some tiny burrs that can only be observed with a microscope.

Ultrasonic deburring is not suitable for all types of machined parts. It has a good effect on deburring the parts that are not visible to the naked eye, but for the visible burrs, this method is not feasible.

In any case, deburring is only a remedy for the final process, although burrs are essential in precision machining. However, in the early production process, if the burrs of the processed parts can be avoided or reduced, a lot of time will be saved in the follow-up.