Fixture refers to the device used to fix the processing object in the mechanical manufacturing process, so that it can occupy the correct position to accept construction or testing. In a broad sense, in the technological process, the devices used to install workpieces quickly, conveniently and safely can be called fixtures.

The fixture is usually composed of positioning element (to determine the correct position of the workpiece in the fixture), clamping device, tool setting guide element (to determine the relative position of the tool and the workpiece or guide the direction of the tool), indexing device (to enable the workpiece to complete the processing of several stations in a single installation, there are two types of rotary indexing device and linear moving indexing device), connecting element and clamp (fixture base).

Fixture Types Can Be Divided Into:

① Universal fixture.

For example, machine vises, chucks, suction cups, dividing heads and rotary workbenches are very versatile and can better adapt to the transformation of processing procedures and processing objects. Their structures have been finalized, and their dimensions and specifications have been serialized. Most of them have become a standard accessory of machine tools.

② Special fixture.

It is specially designed and manufactured for the clamping needs of certain product parts in a certain process. The service object is specific and highly targeted. Generally, it is designed by the product manufacturer itself. Commonly used are lathe jigs, milling machine jigs, jigs (machine tool jigs for guiding the cutter to drill or ream holes on the workpiece), boring dies (machine tool jigs for guiding the boring cutter bar to bore holes on the workpiece) and traveling jigs (mobile jigs for automatic lines of modular machine tools).

③ Adjustable clamp.

A special fixture for replacing or adjusting elements.

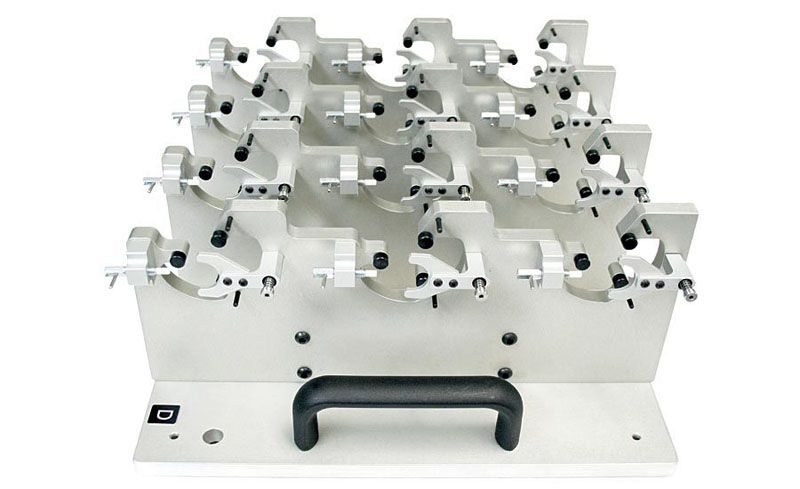

④ Modular fixture.

The fixture consists of standardized components with different shapes, specifications and uses, which is suitable for trial production of new products, single piece, small batch production and temporary tasks where products are often replaced.

In addition to vises, chucks, indexing heads and rotary worktables, there is a more common tool handle. Generally speaking, when the word tool clamp appears at the same time, most of the clamps refer to the tool handle.

Several Types Of Fixtures:

1. Lathe fixture

The fixture used to process the inner and outer revolving surfaces and end faces of workpieces on a lathe is called a lathe fixture. Lathe fixtures are mostly installed on the spindle, and a few are installed on the bed saddle or bed.

2. Three coordinate fixture

It is used on the measuring machine, and its modular support and reference device is used to complete the flexible fixation of the measured workpiece. The device can automatically program, support the workpiece, and establish infinite workpiece configuration reference points. The advanced special software can directly generate the clamping program of the workpiece in a few seconds through the geometric data of the workpiece.

3. Fixture of industrial robot

They are installed on industrial robots and used in industrial automation equipment, which is one of the new technologies of modern industrial automation equipment. The main form of cooperation with robots appears in modern industrial production, and the common usage is in automatic unmanned factories such as machine tool loading and unloading, workpiece unstacking, welding, grinding, etc.

4. Milling machine fixture

All are installed on the milling machine workbench, and the machine workbench is used for feeding movement. It is mainly composed of positioning device, clamping device, clamping device, connecting element and tool setting element. When milling, the cutting force is large, and it is intermittent cutting, and the vibration is large. Therefore, the requirements for the clamping force of the milling machine fixture are large, and the requirements for the fixture stiffness and strength are relatively high.

5. Clamp of bearing seat

In order to ensure the production quality of the bearing pedestal and improve the production quality of the bearing pedestal, in addition to the use of machine tools and other mechanical equipment, a large number of process equipment will be used, including bearing pedestal clamps, molds, tools and related auxiliary tools.

Bearing seat fixture is a production tool specially used to ensure the quality of bearing seat products, which can make the production process of bearing seat more convenient. Different bearing seat clamps are different according to their different structures and forms, working conditions, and design principles. Therefore, the types and styles of bearing seat clamps are diverse, and they account for a large proportion both in number and style.

This kind of bearing seat fixture can be used to accurately determine the relative position of the processing workpiece and the props, that is, the workpiece to be processed can be tightened, so that the movement required in the process of workpiece processing can be completed. Because the fixture of bearing pedestal plays a very important role in the production process of bearing pedestal, the drawing of fixture design drawing of bearing pedestal is also very important.