Nylon 6 and nylon 66 are commonly used synthetic polymers called polyamides. As a variant of polyamide, they have many of the same characteristics, but the type and number of polymer chains in their chemical structure bring differences. In order to simplify the choice of these two plastic materials in engineering applications, here we compare nylon 6 and nylon 66. Both nylon 6 and nylon 66 are ideal for growth and innovation. We examine these two very similar but different fibers to help you make an informed choice when choosing the right material for your project.

As polyamides, although they have their own clear advantages, they also have many core performance characteristics.

- Excellent wear resistance

- Rigidity, hardness and toughness

- High mechanical damping

- Good sliding performance

- High mechanical strength

- Good for electrical insulation

- Strong resistance to high-energy radiation

- Good processability

Therefore, while maintaining these core attribute values, they still provide different attributes.

CNC Machining Plastic Material-Nylon 6

Nylon 6 or polycaprolactam is a semi-crystalline polyamide. Unlike other nylon plastics, it is not a condensation polymer. Nylon 6 fiber is generally white and can be dyed into other colors. It is tough, wrinkle-resistant, abrasion-resistant, and chemical-resistant. It has high tensile strength and impact strength, processability, good elasticity and gloss. It also has excellent abrasion resistance and abrasion resistance, long-term heat resistance, high flame retardant rating (UL 94VO) and high water absorption.

Common Applications Of Nylon 6:

Stadium seats

Knitwear

Radiator grille

Industrial yarn

Toothbrush fiber

Wear-resistant bar and chain guard

Machine guard

Rotor slot wedge

Firearms

Upholstery

Heavy fabric

Circuit insulation board

Switchgear

Seal

CNC Machining Plastic Material-Nylon 66

Nylon 66, also known as nylon 6-6, nylon 6/6, or nylon 6,6, is the more crystalline version of nylon 6. It is also called polyamide 66 or PA 66. Nylon 66 is an amorphous solid with excellent wear resistance, high melting point, high tensile strength, high dimensional stability, high lubricity, resistance to hydrocarbon and light degradation, and an abnormal balance of strength, ductility and resistance Thermal. Good elasticity, waterproof, slightly soluble in boiling water, not easy to dye, but high color fastness, not easy to fade. Typical applications include wear pads, guide wheels and sliding bearings. It is also widely used in electronic components, which is stimulated by improved flame retardancy. It is commonly used as a metal substitute for the body of die-cast hand tools.

Common Applications Of Nylon 66:

Friction bearing

Tire cord

Carpet

Battery module

Car airbag

Conveyor

Parachute

Apparel

Seat belt

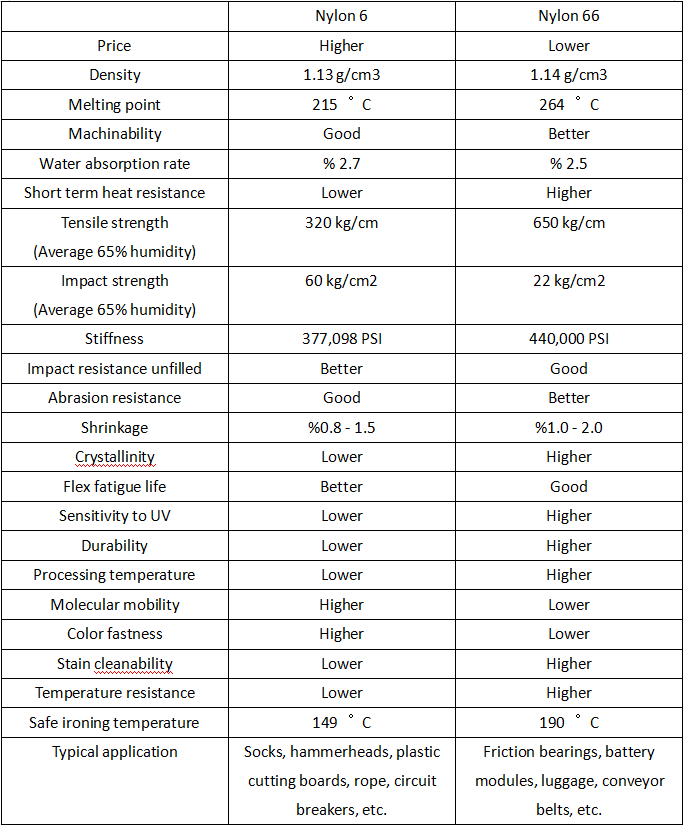

Comparison Between Nylon 6 And Nylon 66

The difference between PA 6 and PA 66 in terms of performance, cost, application, etc.

In order to find out which of nylon 6 and nylon 6-6 to choose, or what application they are suitable for, we have listed a comparison chart of nylon 66 and nylon 6 here. You can easily find the difference between nylon 6 and nylon 66.

Final Thoughts And Comparison

When evaluating suitable nylon for the project, processing methods, aesthetics, and mechanical properties must be considered.

If lightweight engineering plastics are a prerequisite, nylon 6 is a good choice. It has good insulation properties and damping values, as well as good toughness, rigidity and hardness.

If resistance to high impact and internal stress is required and aesthetics is a factor, nylon 6 is also an excellent choice. Its glossy appearance and easy coloring make it a more eye-catching option.

In contrast, nylon 66 is used where high-performance engineering plastics are required in higher temperature environments.

Its higher stiffness and good tensile modulus make it an excellent material for applications that need to last longer in repeatability, such as friction bearings, tire cords or radiator covers.

There are more nylons that need to be considered, each of which has different performance advantages and attribute values. Therefore, it can be seen that among many nylons, choosing the right one is often a favorable compromise.