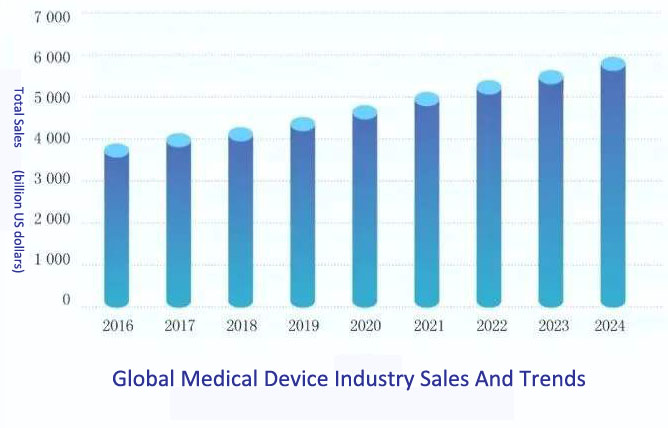

In the post-epidemic era, the public’s health awareness continues to increase, driving the medical and health industry to rise against the trend, and the global demand for medical devices is growing rapidly. According to the Evaluated Med Tech survey, the global medical device market capacity reached 451.9 billion U.S. dollars in 2019. It is predicted that the global medical device market capacity will be close to 600 billion U.S. dollars by 2024, and the global market has great potential for development.

How does precision machining affect the medical industry?

Precision machining has brought many benefits to almost all industries. It even completely changed the way they treat their respective niches. From automation to aviation to manufacturing. One of the most important industries that benefit from precision machining is the medical industry. Without precision machining, many of the medical products we use now will be impossible.

Here, we study how precision machining affects the current and future state of medical progress.

Machining Meet the Tightest Tolerances

Where the medical industry most needs safety, precision and accuracy. Precision machining helps to create accurate dimensions for surgical tools that fit the surgeon’s hands, resulting in more accurate results.

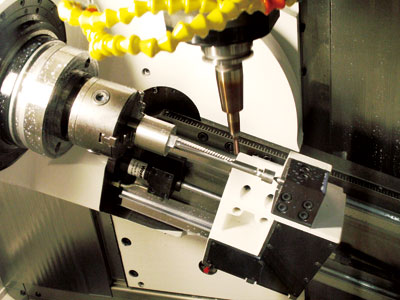

Machining is also used to create complex parts for laser or robotics, which are used to achieve operations that were impossible a few years ago. Mechanical processing will help to create more discoveries and innovations, thereby promoting the development of medicine. These tools require very small and precise parts and tips to function-parts that can only be created by CNC and EDM machining tools.

Because these tools are used for the most delicate surgery (even for blood vessel or brain surgery), even the smallest deviation can have catastrophic consequences. This is where precision machining comes in. It helps to create tools that are not only precise, sophisticated, and precise to achieve safety and reliability.

Wide selection for Variety and Complex of Materials

Materials used in medical institutions need to meet durability, safety, non-reaction to the human body, and disinfection capabilities. For example, joint replacement parts are usually made of medical stainless steel or titanium to obtain unparalleled strength, elasticity and function.

Precision machining makes these materials into complex shapes and sizes for use in specific medical fields. Some of these parts are already embedded in the patient’s body, so they need to meet strict tolerances and have a very smooth surface to eliminate burrs or streaks.

CNC and EDM precision machining are very suitable for creating these precision parts. Even the hardest materials can be used and turned into smooth parts. This processing method ensures that all parts are the same and assembled in the correct way to achieve optimal performance.

Miniaturization for Comfort and Safety

Why do certain medical tools or materials need to be miniaturized? Because only in this way can they provide comfort and safety. Take insulin pumps, heart monitors and defibrillators as examples. Thanks to precision machining, these designs have now been miniaturized with smaller, more precise components. These implants can now be placed in the body, so that these people can live relatively normal lives and enjoy freedom and freedom of movement.

Only through precision machining can these medical tools be precisely designed and manufactured. Once the design is entered into computer control, the parts are processed immediately for smaller or larger runs. In summary, there is no doubt that this technology has made a huge contribution to the medical industry.

Customized Devices

Precision machining also allows custom designs for certain medical devices to achieve more precise and personalized fits. This is especially important for artificial devices (such as artificial knees, artificial limbs), which need to be precisely adapted to and meet people’s needs.

The uniqueness of precision machining is that it can meet this demand. Through CNC machining, customized parts are simple and cost-effective. By inputting the design into the computer control, the parts can be processed quickly and accurately. Precision machining has promoted the development of the medical industry, and in the long run, it is an indispensable part.

Medical precision machining trends and challenges

The accelerated development of the global market will inevitably link its upstream and downstream industrial chains, bring massive medical device processing needs, and bring a new wave of development to the precision parts manufacturing market.

Among them, most of the medical parts have the characteristics of small batches, multiple varieties, irregular shapes, hard materials, and high surface finish. These parts need to be strictly milled, turned and drilled, such as orthopedic implants (mostly using titanium alloy or stainless steel, There are bone plates, artificial joints, bone nails, etc.), dental implants, cardiac pacemaker parts, etc.

Medical equipment is known for its complex structure and high requirements for precision and reliability. The higher requirements for workpiece materials, machining accuracy, and surface finish of medical device parts also mean that precision machining capabilities need to take a new step. Precision processing technology is an advanced manufacturing technology developed to adapt to modern high technology. In recent years, with the deepening of China’s intelligent manufacturing, precision processing technology has made more and more contributions to the medical device industry.

With the development of the medical device industry, there will be more and more types of medical devices, more complex structures, and higher precision requirements. In order to meet the needs of multiple varieties and high precision of medical equipment, high-speed, high-precision, intelligent, compound, and environmentally-friendly precision machining has gradually become the main development direction of CNC machining of medical equipment. That is to say, extremely high requirements are put forward for machine tools, fixtures, cutting tools, CAM software, testing equipment, engineering capabilities, etc. Medical device manufacturers’ demand for high-quality parts processing suppliers has undoubtedly promoted the advancement of processing technology, as well as the competitiveness and production efficiency of this industry of machining companies.

Precision machining has made a huge contribution to the advancement of the medical industry and will continue to be an indispensable part of future progress. Contact SANS immediately and let our high-quality, small-batch fast delivery help you lead your competitors in medical devices, occupy market share, and contribute to human health as soon as possible.