During the machining process of the CNC machining center, whether the selection of the positioning datum is reasonable or not determines the quality of the parts, which has a great influence on whether the dimensional accuracy and mutual orientation accuracy requirements of the parts can be guaranteed, as well as the processing sequence organization between the surfaces of the parts. When the workpiece is installed with a fixture, the selection of the positioning datum will also affect the complexity of the fixture structure. This requires the fixture to not only accept large cutting forces, but also meet the positioning accuracy requirements. Therefore, the selection of positioning datum is a very important process issue.

The positioning reference is divided into fine reference and rough reference: the rough reference uses the unmachined surface on the blank as the positioning reference. The fine datum takes the machined surface as the positioning datum.

The Principle Of Choosing A Fine Benchmark

(1) The principle of datum coincidence: the surface design data after processing should be as accurate as possible to avoid positioning errors caused by data misalignment.

(2) The principle of unified datum: In order to ensure the relative positional accuracy between the machined surfaces, as many surfaces as possible on the workpiece should be machined using the same set of fine datums as much as possible.

(3) Mutual datum principle of workpiece machining surfaces: The repeated machining method of two machining surfaces can be used as a mutual reference.

(4) Self-based benchmark principle: Some surface finishing processes require small and uniform processing tolerances, often using the processed surface itself as the accuracy benchmark.

The above-mentioned four principles for selecting a precise benchmark are sometimes impossible to satisfy at the same time, and must be decided according to the actual situation.

Principles For Choosing Rough Benchmarks

(1) The rough datum should be used in the first workpiece processing. Whether the rough datum is selected correctly not only affects the processing of the first process, but also has a great influence on the entire process of the workpiece.

(2) The principle of reasonable distribution of machining tolerances: The machining allowance on the surface of the workpiece should be kept uniform, and the important surface should be used as the rough benchmark.

(3) Principle of easy clamping: In order to stabilize the positioning of the workpiece and the clamping is reliable, the selected approximate reference point is required to be as smooth and clean as possible, without lightning strikes, and sufficient supporting area is allowed for forging cuts or other defects.

When Machining Parts With A CNC Machining Center, How To Select The Positioning Datum?

- The selected datum should be able to ensure accurate positioning of the workpiece, convenient loading and unloading of the workpiece, agile positioning and clamping of the workpiece, reliable clamping, and simple fixture structure.

- The benchmark selected by the CNC machining center and the various scale operations of each processing part are simple, and the scale chain calculation is minimized to prevent or reduce the calculation link and calculation error.

- Ensure the machining accuracy. The following guidelines should be followed when confirming the positioning datum of the part in detail:

(1) The origin of the workpiece coordinate system, that is, the “programming zero point” and the part positioning datum do not necessarily have to coincide, but it is necessary to have a confirmed geometric connection between the two. The selection of the origin of the workpiece coordinate system mainly considers the convenience of programming and measurement. For parts with high dimensional accuracy requirements, when confirming the positioning datum, it should be considered whether the origin of the coordinates of the CNC machining center can be accurately measured through the positioning datum.

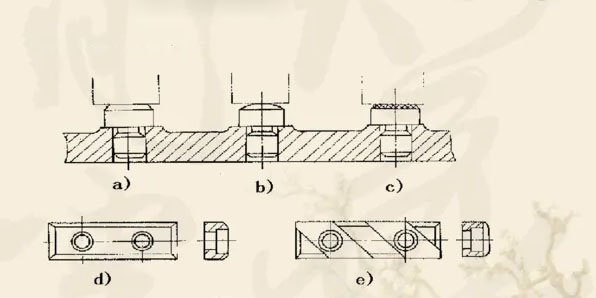

(2) When processing the datum and completing the processing of each station on the CNC machining center, the selection of the positioning datum needs to consider the completion of as many processing contents as possible. For this reason, it is necessary to consider the positioning method that is convenient for all surfaces to be processed. For example, for the box, it is best to use a positioning method with two pins on one side, so that the tool can process other surfaces.

(3) Try to select the planning datum on the part as the positioning datum. This requires that during rough machining, consider what kind of rough datum is used to process all sides of the fine datum, that is, each positioning datum used in the CNC machining center should be processed in the previous general machine tool or other machine tools, so that it is easy to ensure that each work is completed. The precision relationship between the bit-machined surfaces.

(4) When the positioning reference and the design reference of CNC machining center parts are difficult to coincide, the assembly drawings should be carefully analyzed to confirm the design function of the part design reference, and the shape and position between the positioning reference and the design reference should be strictly specified through the calculation of the standard chain The range of public service ensures the machining accuracy.

(5) When the station processing including the planning benchmark cannot be completed at the same time on the CNC machining center, the positioning benchmark should be made to coincide with the planning benchmark as much as possible. At the same time, it should also be considered that after using this reference positioning, the machining of all key precision parts can be completed in one clamping.