CNC lathe is one of the most widely used CNC machine tools. It is mainly used to process symmetrical rotary parts, such as shaft parts, inner and outer cylindrical surfaces of disc parts, inner and outer conical surfaces with arbitrary cone angles, complex revolving inner and outer curved surfaces and cylindrical, conical threads and other cutting processes.

Even the most common turning contours have different processes. In some CNC systems, these process options are included in “transverse turning”, “longitudinal turning (also known as “reciprocating turning”)” and “groove cutting”. Among the classes, let us understand together below.

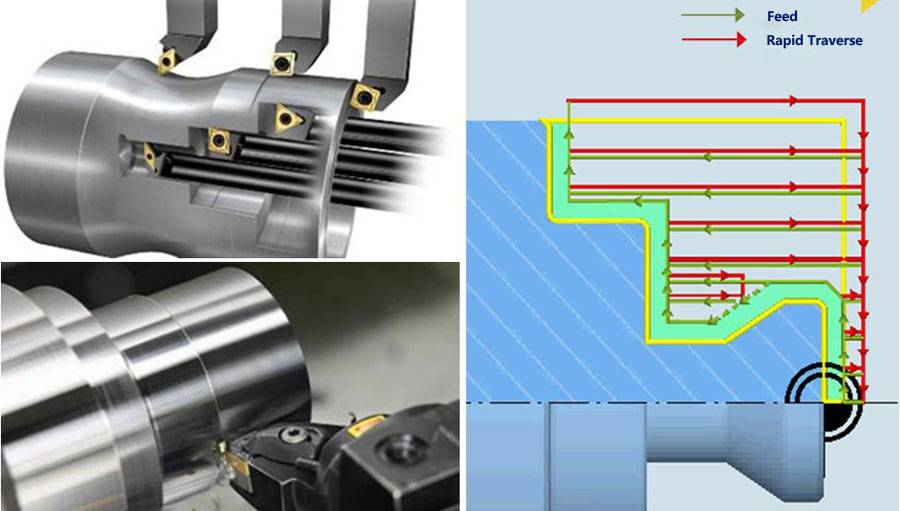

1. Horizontal turning

Features of Horizontal turning:

- In horizontal turning, the moving direction of the turning tool is parallel to the axis of rotation of the workpiece.

- If it is the main spindle, the moving direction of the tool is from right to left; if the machine is equipped with a sub-spindle, the moving direction of the tool is from left to right.

- Transverse turning can be used to machine outer circles and inner holes. However, when processing the inner hole, a bottom hole must be pre-drilled first.

- In addition to outer circle processing, end face processing is also possible.

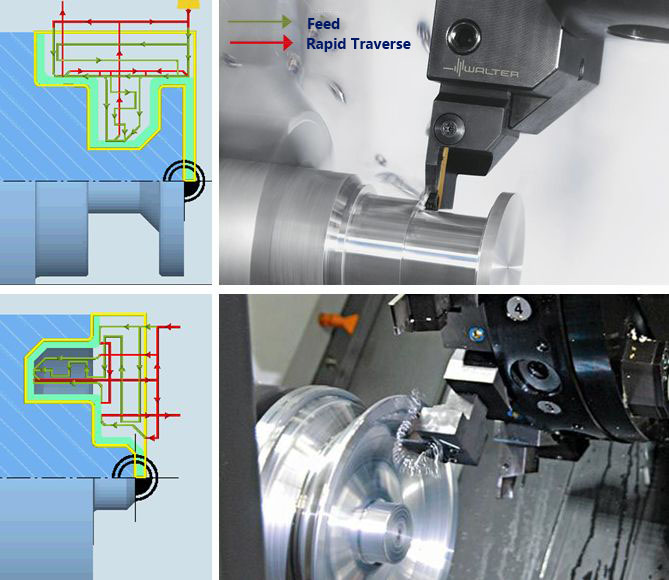

2. Longitudinal Turning, Groove Cutting And Cutting

Longitudinal turning characteristics of side and end faces (also called “reciprocating cutting”):

- When longitudinal turning is performed on the side of the workpiece, the feed direction of the slitting turning tool is perpendicular to the axis of rotation of the workpiece.

- In the longitudinal turning of the end face of the workpiece, the feed direction of the slitting turning tool is parallel to the workpiece axis.

- The slitting turning tool has three cutting edges, so that the material removal process in the radial and axial directions is as uninterrupted as possible (because the rapid movement stroke is minimized).

- The shape of the blade and the shape of the blade of the grooving knife and the slitting knife are different.

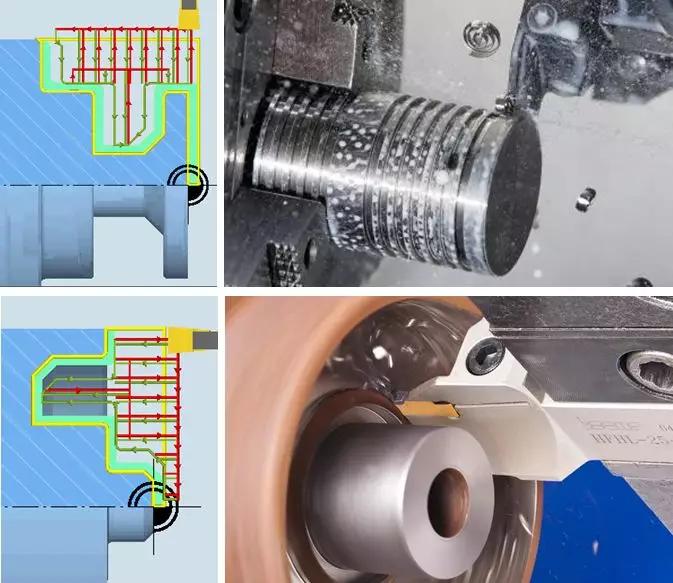

Groove cutting features of side and end surfaces:

- When grooving, only cut in the transverse feed direction.

- The machining process of side groove cutting is perpendicular to the direction of the axis of rotation.

- The machining process of face groove cutting is parallel to the direction of the axis of rotation.

- The grooving tool can only withstand the force applied perpendicular to the axis of the tool.

- The groove cutting process is mainly used to machine grooves. Normally (not absolutely) the groove to be machined has the same width as the grooving tool.

3. Summary

Horizontal Turning:

+ Large cross feed can be achieved, that is, a large chip cross-sectional area

+ High feed rate can be achieved during roughing

+ Perfect chip discharge effect

-Not all contours can be processed with limited tools for lateral turning, and more tools may need to be replaced during processing

Longitudinal Turning:

+ Avoid empty cutting stroke

+ Reduced tool change operations

+ High flexibility in application

-Due to tool limitations, not all contours can be machined

-The chip discharge effect is sometimes not ideal (the chips may be stuck)

When to use which process?

Longitudinal turning is generally used: for example, the machining of parts with deep grooves and 90°corner structures. The machining of these structures can only be done by this process.

Horizontal turning is generally used for streamlined contour structures with arc transitions.