Press fits, a method of joining components by inserting one part tightly into another, play a crucial role in assembly design. The decision to use a press fit involves a delicate balance between achieving a secure connection and avoiding potential issues. In this post, we explore the considerations for employing press fits in assemblies, addressing when they are advantageous and when alternative methods might be preferred.

Understanding Press Fits:

The Basics:

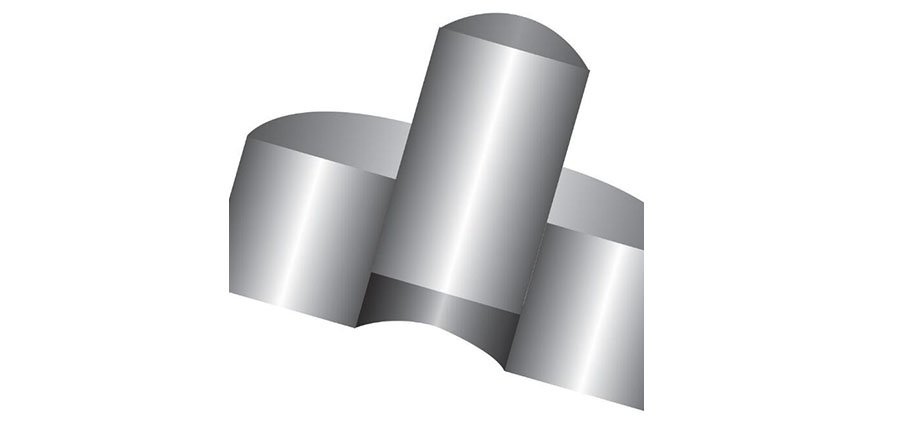

A press fit involves joining two cylindrical components where the outer diameter of one part is slightly larger than the inner diameter of the other. When assembled, the parts are forced together, creating an interference fit. The resulting friction and pressure hold the components securely in place.

Types of Press Fits:

Press fits can be categorized based on their interference levels. The common types include:

Light Press Fit: Minimal interference, allowing for easy assembly and disassembly.

Medium Press Fit: A tighter fit offering increased resistance to axial movement.

Heavy Press Fit: Significant interference for a secure, permanent assembly.

Advantages of Press Fits:

- No External Fasteners:

Press fits eliminate the need for external fasteners such as screws or bolts. This not only streamlines the design but also provides a cleaner, more aesthetically pleasing appearance.

- Uniform Stress Distribution:

When executed correctly, press fits distribute stress uniformly across the engaged surfaces. This can enhance the overall strength and integrity of the assembly.

- Space Efficiency:

Press fits can be more space-efficient than traditional fastening methods, making them particularly advantageous in compact designs or where minimizing weight is crucial.

- Cost-Effective:

As press fits often don’t require additional fasteners or hardware, they can be a cost-effective solution, both in terms of material and assembly costs.

Considerations for Press Fits:

- Tolerance Control:

Tight tolerance control is critical when using press fits. The dimensions of mating parts must be precisely controlled to achieve the desired interference fit. This can pose challenges in manufacturing, especially for large-scale production.

- Material Selection:

The materials of the mating components play a significant role in the success of press fits. Materials with suitable hardness and rigidity are preferred to withstand the stresses associated with press fitting.

- Thermal Considerations:

Temperature variations can affect the dimensions of materials. Engineers must consider the thermal environment in which the assembly will operate to ensure that press fits maintain their integrity across different temperatures.

- Press Fit Interference:

Determining the right amount of interference (the difference in size between the hole and the shaft) is crucial. Too much interference can result in stress concentrations and difficulty in assembly, while too little can lead to a loose fit.

Alternatives to Press Fits:

- Threaded Fasteners:

Where disassembly and reassembly are expected, threaded fasteners like screws or bolts may be more suitable. They offer the advantage of adjustability and ease of maintenance.

- Adhesives:

Adhesive bonding provides an alternative to mechanical fastening. It’s especially useful in applications where aesthetics, weight, or vibration resistance are significant factors.

- Snap Fits:

In situations where parts need to be assembled and disassembled repeatedly, snap fits can be a suitable alternative. They provide a secure connection while allowing for convenient disassembly.

Conclusion:

Choosing between a press fit and alternative assembly methods requires a thoughtful evaluation of the specific application, materials, and design goals. Press fits offer advantages in terms of simplicity, space efficiency, and cost-effectiveness, but careful consideration of tolerances, materials, and environmental factors is essential to ensure a successful and reliable assembly. As with any engineering decision, the choice should be driven by a comprehensive understanding of the unique requirements and constraints of the given project.

A thorough understanding of the forces at play, precision in manufacturing, and consideration of the application’s unique requirements are vital to achieving a perfect harmony in the assembly process. SANS Machining is your operating system for custom manufacturing that makes part procurement faster, easier, and more efficient.