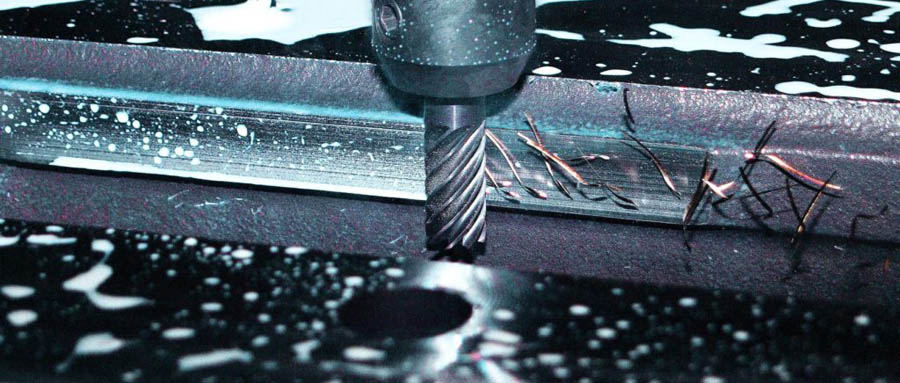

The widespread use of CNC manufacturing and processing equipment has promoted the development of cutting technology. We have witnessed the improvement of efficiency, the improvement of product quality and the ability to produce almost all products with precise precision.

With the emergence of super heat-resistant alloys and composite materials, the quality requirements for cutting tools are becoming more and more stringent. Tool wear is the most common. After working for a long time, malfunctions or malfunctions may occur. In fact, every cutting tool experiences wear during its production life.

Although this is common, excessive wear is not good for our products or machines. The inconsistency caused by this wear may adversely affect your work piece and may damage major equipment. Tool wear can also cause failures, which can lead to serious damage, rework, and scrapped parts.

Therefore, it is very important to find out such anomalies and correct them in real time so that we can get the best end mill performance. Based on our experience, here are our views on various types of tool wear and how to identify and mitigate them. Hope they can help you better manage tool wear!

CNC tool wear factors

What is tool wear? Tool wear is the gradual failure of the tool due to regular operation. There are many factors that cause rapid wear of cutting tools.

1) Mechanical wear

Processing hard or difficult materials can easily lead to rapid wear of cutting tools. Most difficult-to-process materials are characterized by low thermal conductivity, which leads to a decrease in the bond strength of the adhesive in the tool material at high temperatures and accelerates tool wear.

2) Cutting heat

When cutting materials with high hardness and toughness, the temperature of the cutting edge is very high, and the wear of the tool is similar to when cutting difficult-to-machine materials. Especially when processing workpiece materials that produce short chips, craters wear near the cutting edge and damage the tool in a short time.

3) Chemical wear

When cutting, the components in the difficult-to-machine material and some components in the tool material will react under high temperature conditions, these components will precipitate, fall or generate other compounds, which will accelerate tool wear, such as collapse.

Types of tool wear and how to avoid them

This is some common tool wear methods in CNC cutting.

1. Abrasive wear

The wear zone is a mode of uniform wear on the tool cutting edge, which is caused by the mechanical wear of the workpiece. This will make the cutting edge of the tool blunt, and even change the size. If severe thermal stress occurs at a higher speed, it will even change the size of the knife edge, especially if the appropriate tool coating is not used. The cutting edge causes more damage, so the tool coating is essential for extending tool life.

How to avoid

If the wear area becomes too large or the tool is damaged prematurely, reducing the cutting speed and optimizing the amount of coolant used will help. High efficiency milling (HEM) tool paths can help reduce wear by spreading the work done by the tool over the entire cutting length. This prevents localized wear and extends tool life by using the entire available cutting edge.

2. Chipping

Fragmentation is caused by many different reasons, such as excessive impact, thermal cracking or wear during operation. Think of it as a series of chips or spalling bits on a cutting tool. If not corrected in time, this wear usually results in poor surface finish and may even lead to serious tool failure.

How to avoid

Cracking is usually caused by excessive loads and shock loads during operation, but it can also be caused by thermal cracking (another type of tool wear). There are several steps to check whether your cutting tool has cracked. First, you need to make sure that the CNC milling machine does not vibrate or chatter. Then adjust the speed and feed rate accordingly, increase the speed and reduce the feed rate.

3. Thermal cracking

Thermal cracks are caused by temperature fluctuations during milling. They are identified as a series of cracks on the tool surface perpendicular to the cutting edge. The rate of crack formation is slow, but it can lead to cracking and premature tool failure.

How to avoid

Hot cracks are usually identified by tool cracks perpendicular to the cutting edge. One of the best ways to transfer thermal cracks is to add an appropriate heat-resistant coating to the end mill. Similar to wear, HEM toolpaths provide excellent thermal crack protection because these toolpaths spread heat across the entire cutting edge of the tool, thereby reducing overall temperature and preventing severe heat fluctuations.

4. Fracture

As the name suggests, fracture refers to the sudden break of the tool during machine operation. Fracture is the complete loss of tool usage due to sudden fracture, which is usually caused by improper speed and feed, incorrect coating or improper cutting depth. The problem of the tool holder or the loosening of the workpiece can also cause fracture, and the inconsistent material properties of the workpiece can also cause fracture.

How to avoid

Adjusting the speed, feed and depth of cut and checking the rigidity of the setting will help reduce cracking. Optimizing the use of coolant also helps avoid hot spots in the material, which can dull the cutting edge and cause fracture. The HEM toolpath prevents fracture by providing a more consistent load on the tool. Reduce the impact load, thereby reducing the pressure on the tool, thereby reducing the possibility of damage and extending the life of the tool.

Conclusion

It is important to monitor the tools and keep them in good working order to avoid downtime and save money. Wear is caused by both thermal and mechanical forces. It can be run by using appropriate operating parameters and HEM tool paths to spread wear across the entire cutting length, thereby reducing wear. Although every tool will eventually suffer some degree of tool wear, if you pay close attention to speed, feed, and depth of cut, the effect may be delayed. Preemptive action should be taken to correct the problem, so as not to cause a complete failure of the tool.