With the needs of production, many special parts and structures have appeared in various walks of life. Correspondingly, in order to adapt to the characteristics of many varieties of parts and small batches, the importance of EDM has become more and more obvious. EDM technology occupies an important position in the manufacturing field. For a long time, EDM (EDM) has been a high-precision, high-demand solution, and is an effective means to achieve precise machining of difficult materials and complex parts.

Therefore, through this article let us know in detail what is EDM, what is its processing flow and specific advantages.

What is EDM Machining

Electrical discharge machining (EDM) is a manufacturing process, known by many other names, including spark machining, arc machining, also called as wire-cut EDM, wire cutting, edm cutting, wire burning, wire erosion.

Electrical discharge machining (EDM) is a manufacturing process, known by many other names, including spark machining, arc machining, also called as wire-cut EDM, wire cutting, edm cutting, wire burning, wire erosion.

EDM is an unconventional method that does not require mechanical force during the removal process, uses a single thin wire, and uses the heat generated by electric sparks together with deionized water to cut the metal, the cutting wire does not touch the material, and prevents rust .

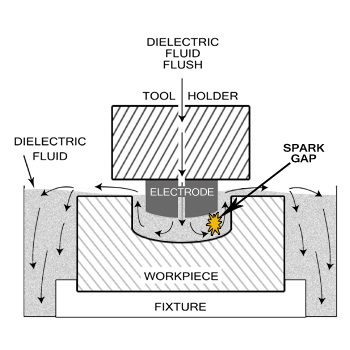

The current is separated between the electrode and the workpiece by a dielectric fluid, and the current passes through the electrode and the workpiece. Unless sufficient voltage is applied to make it an electrical conductor, the dielectric fluid will act as an electrical insulator. The spark discharge produced corrodes the workpiece to form the desired final shape. During this process, current is used to cut the conductive material and leave a smooth surface without the need for other finishing or polishing processes. Generally, the electrode diameter range is .004″-.012″ (.10mm-.30mm), and the diameter can be larger or smaller.

In the manufacture of tools and precision parts, EDM is very popular because of its applicability, especially for hard materials such as titanium or particularly complex shapes that are difficult to obtain by milling。

How does EDM work?

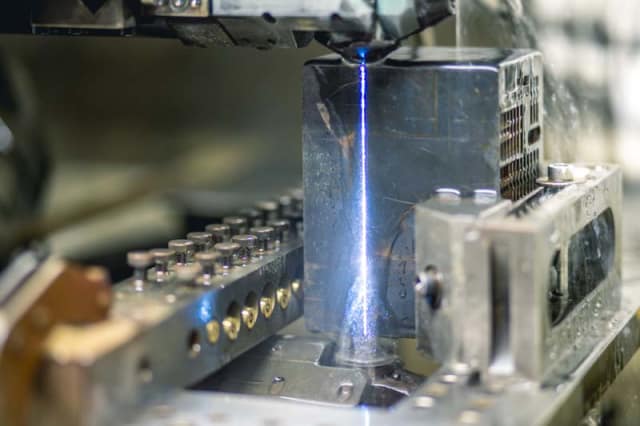

Wire cutting is performed by generating electrical discharges on the wire or between the electrode and the workpiece. EDM cutting always runs through the entire workpiece. To start wire machining, you must first drill a hole in the workpiece or start from the edge. In the machining area, each discharge will produce a pit in the workpiece and affect the tool. The wires can be inclined, so parts with tapered or different profiles can be made on the top and bottom. As the spark jumps across the gap, the material is then removed from the workpiece and electrode.

Wire cutting is performed by generating electrical discharges on the wire or between the electrode and the workpiece. EDM cutting always runs through the entire workpiece. To start wire machining, you must first drill a hole in the workpiece or start from the edge. In the machining area, each discharge will produce a pit in the workpiece and affect the tool. The wires can be inclined, so parts with tapered or different profiles can be made on the top and bottom. As the spark jumps across the gap, the material is then removed from the workpiece and electrode.

In order to prevent a short circuit in the spark process, a non-conductive fluid or dielectric is also used in the process. The waste is removed by the dielectric, and the process continues. There is absolutely no mechanical contact between the electrode and the workpiece. The wires are usually made of brass or layered copper and have a diameter between 0.1 and 0.3 mm.

EDM Machining Types

While there are many specialized forms of electrical discharge machining, industrial EDM machines are commonly grouped into three categories: Die Sinker EDM, Wire EDM, Hole Drilling EDM.

Sinker EDM

Sinker EDM, also known as ram EDM, conventional EDM or plunge EDM, uses machined electrodes with different shapes, sizes and materials to remove material from the workpiece. The electrode is usually made of graphite, but copper, tungsten or brass and combinations of these materials can also be used, and the geometric characteristics of the electrode can be customized to achieve the required specifications.

In the sinker EDM process, both the workpiece and the electrode are immersed in an insulating fluid of oil or synthetic oil, and the machine uses CNC technology to automatically direct the electrode to the workpiece. As with wire EDM, when the electrode approaches the workpiece, the strength of the charge breaks the barrier of the dielectric fluid and generates a spark, which erodes a small amount of material by melting and vaporizing tiny particles.

This process is repeated hundreds of thousands of times per second, and while removing material, the machine will continue to control the movement of the electrode until it reaches the desired size. Today, die EDM is used to create complex cavity shapes in tool and die applications.

Wire EDM

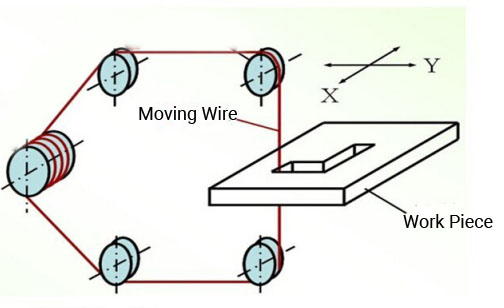

It is a non-traditional processing technology, which uses electricity to take fine charged copper or brass wire as an electrode to cut any conductive material accurately and accurately. The basic working principle is to use a continuously moving thin metal wire (called an electrode wire) as an electrode to perform pulse spark discharge on the workpiece to remove the metal and cut the shape.

It is a non-traditional processing technology, which uses electricity to take fine charged copper or brass wire as an electrode to cut any conductive material accurately and accurately. The basic working principle is to use a continuously moving thin metal wire (called an electrode wire) as an electrode to perform pulse spark discharge on the workpiece to remove the metal and cut the shape.

In many cases, the entire part is immersed in the dielectric fluid, and during the cutting process, the high-pressure upper and lower nozzles remove the fine debris in the area around the wire. The fluid also acts as a non-conductive barrier, thereby preventing the formation of conductive channels in the processing area. When the wire is close to the part, the electric field strength overcomes the obstacle and a dielectric breakdown occurs, causing current to flow between the wire and the workpiece, thereby generating an electric spark.

According to the different operating speeds of the electrode wire, the wire EDM machine tools are generally divided into two categories: one is the high-speed wire EDM machine (WEDM-HS), the electrode wire for high-speed reciprocating movement, the general wire speed is 8 ~10m/s, the electrode wire can be used repeatedly, and the processing speed is high, but the fast wire walking is easy to cause the electrode wire to shake and stop in the reverse direction. The other type is the low speed wire EDM machine (WEDM-LS), which The electrode wire moves at a low speed in one direction, and the general wire walking speed is less than 0.2m/s. The electrode wire is no longer used after discharge. The work is stable, uniform, low jitter, and the processing quality is good, but the processing speed is low.

According to the different operating speeds of the electrode wire, the wire EDM machine tools are generally divided into two categories: one is the high-speed wire EDM machine (WEDM-HS), the electrode wire for high-speed reciprocating movement, the general wire speed is 8 ~10m/s, the electrode wire can be used repeatedly, and the processing speed is high, but the fast wire walking is easy to cause the electrode wire to shake and stop in the reverse direction. The other type is the low speed wire EDM machine (WEDM-LS), which The electrode wire moves at a low speed in one direction, and the general wire walking speed is less than 0.2m/s. The electrode wire is no longer used after discharge. The work is stable, uniform, low jitter, and the processing quality is good, but the processing speed is low.

Wire EDM process has an important limitation: the wire must pass entirely through the workpiece. Wire EDM can only machine through features. If the part’s features do not allow you to cut an edge, we can quickly drill a hole in any conductive material using another type of EDM, small hole drilling

Hole Drilling EDM

Small hole drilling EDM uses hollow circular electrodes to drill holes on the workpiece. Like wire EDM, drilling EDM uses spark corrosion to remove material. However, in EDM drilling, the size of the hole is controlled by the diameter of the electrode. Even in hardened or heterogeneous materials, accurate and precise holes can be created, which has become a key development of several advanced technologies.

During the EDM process, the dielectric fluid is pumped through and around the electrode to cool and wash away the eroded particles. CNC drilling EDM can quickly and easily drill multiple holes unattended without manual positioning. The small hole EDM is ideal for parts that require start-up holes, ventilation holes, coolant holes, thimble holes, or other blind holes, and is very useful for removing broken taps and drill bits.

EDM VS Wire EDM

Same Points:

Same Points:

1. Both types of machining are a kind of electrical discharge machining, which is based on the pulse power supply, and the workpiece must be a conductor.

2. Same processing principles, and the metal generated by the heat generated by the electric discharge discharge is melted to remove the metal, so the difficulty of the processing material of the two has nothing to do with the hardness of the village material, and there is no significant mechanical cutting force in the processing.

Different Points

1. The main processing object of the EDM forming machine tool is to print delicate patterns or curved surfaces on the surface. The EDM wire cutting machine tool mainly processes flat workpieces. The movement of wire EDM is to move the workpiece, and EDM is processed by moving the electrode.

2. EDM can process through-holes and blind holes, suitable for processing the cavity of complex-shaped plastic molds and other parts as well as engraving text, patterns, etc.. Wire EDM can only process through-holes, which can easily process small holes Holes, narrow slits with complex shapes and various complex parts.

Advantages Of EDM

- It is suitable for difficult-to-cut materials. It can be used to process hard and tough materials such as polycrystalline gold and cubic boron nitride with soft tools, without being restricted by traditional processing.

- Because the electrode and the workpiece are not in contact during the manufacturing process, it is possible to process and produce small holes, deep holes and narrow slit parts.

- It can process parts with special conductive materials and complex shapes.

- The surface produced by electrical discharge machining has a good finish and high precision.

- Electric discharge machining of hardened materials can avoid any potential deformation from heat treatment machining.

- Can reach shapes and depths that cannot be achieved with cutting tools. Especially in deep machining, the length to diameter ratio of the tool is very high.

- EDM process is very predictable, accurate and repeatable

- All EDM processing is unattended, so the direct labor rate and manufacturing costs of EDM are usually lower compared to other methods

Application Of EDM

EDM was invented in the 1940s and is a very early non-traditional process. Combined with computer numerical control (CNC), it has become an accurate and reliable machining method, and now it has become the standard in more conventional cutting methods. It is often an ideal choice for the production of small, highly detailed items that would normally be too delicate for other machining options. It is especially popular for customized needs or small batch production (such as prototypes). EDM can perform various processes, including turning, milling, grinding and small hole drilling. In addition to mold manufacturing, EDM is also commonly used in automotive, medical, aerospace, etc.

Same Points:

Same Points: