With the development of science and technology, machinery manufacturing technology has undergone profound changes. As society’s demand for product diversification is stronger, the proportion of multi-variety, medium and small batch production has increased significantly, and it has been difficult to adapt to the high-efficiency, high-quality, and diversified processing requirements with traditional ordinary processing equipment. The application of machine tool numerical control technology has greatly increased It shortens the preparatory time of mechanical processing, and continuously improves the automation level of the whole process of mechanical processing. At the same time, it also enhances the ability of the manufacturing system to adapt to changes in various production conditions.

Wire EDM machining include Medium-speed WEDM, low-speed WEDM and high-speed WEDM.

High-speed Wire EDM (WEDM-HS).

The electrode wire (usually molybdenum wire) is used for high-speed reciprocating movement, and the wire speed is 8-10m/s. The electrode wire can be reused, which saves molybdenum wire, but the accuracy is low. It is generally used by domestic wire cutting machines, which is unique in China. Wire EDM machining mode.

Medium-speed Wire EDM(WEDM-MS)

The working principle is to use the continuously moving molybdenum wire (called electrode wire) as the electrode to perform pulse spark discharge to remove metal and cut the workpiece. Its wire speed and workpiece quality are between fast wire and slow wire, so it is called medium wire cutting. Medium wire is an upgraded product of fast wire, so it can also be called: fast wire that can be cut multiple times. Therefore, its processing speed is close to fast-moving wire, and the processing quality also tends to slow-moving wire. The wire speed is between 1 and 12m/s, which can be adjusted as required.

Low-speed Wire EDM(WEDM-LS)

The electrode wire of the low-speed wire cutting machine uses copper wire as the tool electrode, and the electrode is continuously moved to perform pulse spark discharge ablation and cutting of the workpiece. It is mainly used for processing all kinds of complicated and precise small workpieces. The current precision can reach 0.002mm, and the surface quality is close to the grinding level. The electrode wire is no longer used after discharge, and uses a non-resistance anti-electrolysis power supply, usually with automatic wire threading and constant tension devices. The work is stable, uniform, low jitter, high processing accuracy, and good surface quality, but it is not suitable for processing large thickness workpieces. Due to the precise structure of the machine tool, the high technical content and the high price of the machine tool, the use cost is also high.

The Difference Between High-speed Wire EDM and Low-speed Wire EDM

Many people have been confused about the difference between High-speed wire EDM and low-speed wire EDM. Here we will give you a detailed introduction to the difference between High-speed wire and low-speed wire in WEDM.

1. The wire speed is different.

In the wire cutting machine tool, WEDM-HS and WEDM-LS are distinguished according to the wire walking speed when the electrode wire is working.

The wire speed of high speed wire is generally 300-700m/min. The wire speed of low speed wire is generally 3-15m/min.

2. The electrode wire material is different.

The electrode wire material of the high-speed wire cutting machine is molybdenum wire and tungsten-molybdenum alloy. The electrode wire of low-speed wire generally adopts copper wire or other metal-coated wire.

3. Electrode wire diameter.

The diameter of the wire electrode wire for high-speed wire cutting machine tools is 0.03 to 0.25mm, and the commonly used diameter is 0.12 to 0.2mm, while the diameter of the wire electrode wire for low-speed wire cutting is 0.15 to 0.3mm, and the commonly used diameter is 0.25mm.

4. Different working fluids.

The requirements for WEDM-HS are not too strict, and the working fluid is generally emulsion. The working fluid of the WEDM-LS is deionized water or kerosene, and a filtration system is also required to continuously filter the impurities in the working fluid during production.

5. Different accuracy.

WEDM-HS is the electrode wire recycling, as the electrode wire continues to wear, affecting the machining accuracy. The precision of the products processed by WEDM-HS is ±0.015~0.02mm.

The electrode wire of the WEDM-LS is not recycled, which greatly improves the machining accuracy. The machining accuracy of the machine tool can reach ±0.002mm.

6. The cost is different.

WEDM-HS machine tools are more common and have low technical content. There are more manufacturers and the machine tools are cheap. Moreover, the molybdenum wire is recycled, the processing efficiency is also high, and the processing cost is low.

The WEDM-LS machine has high technical content and expensive equipment. The processing cost is also high.

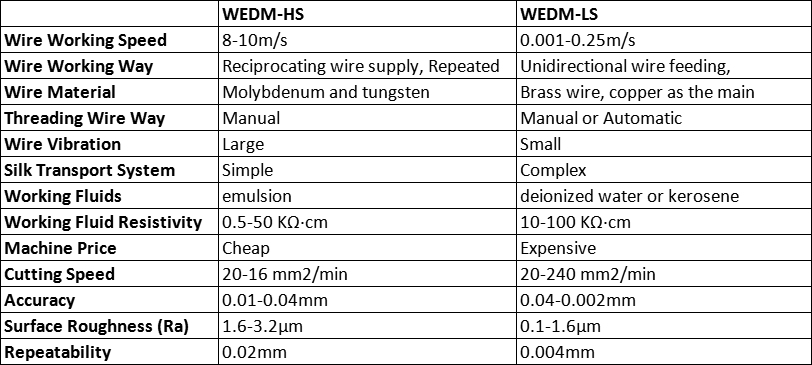

Let me share with you the comparison table of WEDM-LS and WEDM-HS, so that you can compare them more intuitively.

We provide Wire EDM machining services with high precision and close tolerances. SANS also can provide micro hole and small hole EDM drilling services on complex parts.