Over-positioning is also called repeated positioning. The positioning in which the same degree of freedom of the workpiece is repeatedly restricted by 2 or more support points is called over-positioning. Whether the workpiece is allowed to be over-positioned or not should be determined according to the specific situation. Over-positioning should be used properly. Sometimes, over-positioning will cause the workpiece to be unable to be installed normally or cannot guarantee the processing requirements.

In mechanical machining, over-positioning will cause deformation of the workpiece in most cases, and the process reference will change, making the position of the processed part out of tolerance, and the processing accuracy cannot be guaranteed. However, for processing thin-walled or slender workpieces, the result is that the workpiece is not processed smoothly, the tool is shaken, and the tool is even broken and waste is processed.

Whether Over Positioning Is Allowed Depends On The Specific Circumstances.

- If the positioning surface of the workpiece is machined, and the shape, size, and position accuracy are high, over positioning is allowed, and sometimes it is necessary. Because the reasonable over-positioning will not only not affect the machining accuracy, but will also enhance the rigidity of the process system and increase the positioning stability.

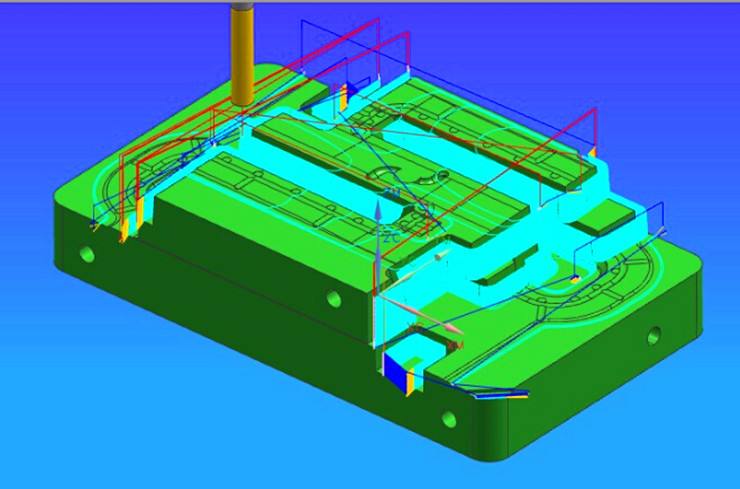

In the positioning scheme shown in the figure, if the positioning plane of the workpiece is large and the machining is very flat, and the working surfaces of the 4 supporting nails are accurately located in the same plane (installed on the fixture to be ground once), then it is not It will cause undesirable consequences due to over-positioning, on the contrary, it can increase the stability of the positioning and increase the rigidity of the support.

- On the contrary, if the positioning surface of the workpiece is a rough surface, or although the machining accuracy is not high although machining is performed, over positioning is generally not allowed at this time, because it may cause inaccurate positioning, unstable positioning or positioning interference, etc. Happening.

The Following Measures Can Be Taken To Eliminate Over-positioning According To The Actual Positioning State:

① Reduce the contact surface of the supporting plane.

② Shorten the contact length of the positioning cylindrical surface.

③ Make the over-positioning component float in the over-positioning direction.

④ Modify the shape of positioning components (such as diamond pins) to reduce contact.

⑤ Remove excess over-positioning components.