Isn’t the CNC tool used in the machining center as fast as possible? Why passivation?

In fact, tool passivation is not what everyone understands literally, but a way to improve tool life.

Improve the quality of cutting tools through processes such as leveling, polishing, and deburring. This is actually a normal process after the tool is finely ground and before the coating.

What Is Tool Passivation?

By deburring, leveling, and polishing the tool, the quality of the tool is improved and the service life is prolonged. The name of the process before the finish grinding of the tool and the coating is not unified at home and abroad. It is called “blade dulling”, “blade strengthening”, “blade honing”, “blade preparation” or “blade preparation”. ER (Edge Radiusing) processing” and so on.

The Advantages And Purpose Of Tool Passivation

1. Resistance to physical wear of the tool

In the cutting process, the tool surface will be gradually worn by the workpiece, and the cutting edge is also prone to plastic deformation under high temperature and high pressure during the cutting process. The passivation treatment of the tool can help the tool to increase the rigidity and avoid the tool from losing its cutting performance prematurely.

2. Maintain the finish of the workpiece

Burrs on the cutting edge of the tool will cause the tool to wear and the surface of the workpiece will become rough. After passivation treatment, the cutting edge of the tool will become very smooth, chipping phenomenon will be reduced correspondingly, and the surface finish of the workpiece will be improved.

3. Convenient for groove chip removal

Polishing the tool groove can improve the surface quality and chip removal performance. The smoother the surface of the groove, the better the chip removal, and more consistent cutting can be achieved.

After the cutting tool of the CNC machine tool is passivated and polished, there will be many small holes on the surface. These small holes can absorb more cutting fluid during processing, which greatly reduces the heat generated during cutting and greatly improves the cutting speed.

The Main Effect Of Tool Passivation

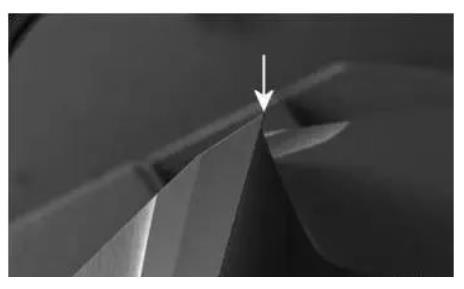

Rounding of the cutting edge

Removal of burrs on the cutting edge to achieve precise and consistent rounding. Cutting edge burrs cause tool wear, and the surface of the processed workpiece will become rough. After passivation treatment, the cutting edge becomes very smooth, which greatly reduces chipping and improves the surface finish of the workpiece.

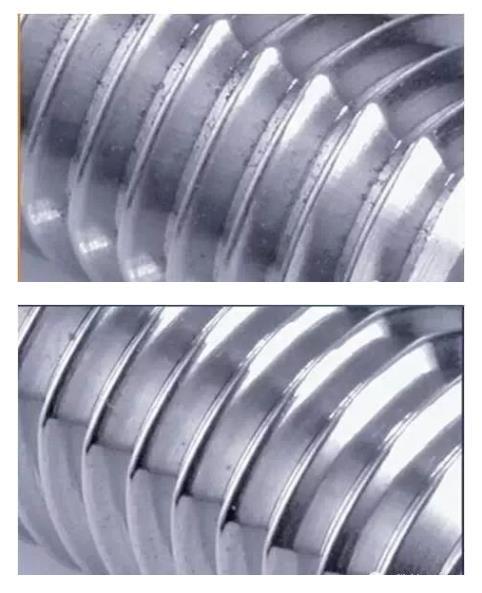

Polishing of the row groove

Evenly polish the tool groove to improve the surface quality and cutting performance.

The smoother the groove surface is, the better the chip removal, and higher speed cutting can be achieved. At the same time, after the surface quality is improved, the risk of seizure of the tool and the processing material is also reduced. It can reduce the cutting force by 40% and cut smoothly.

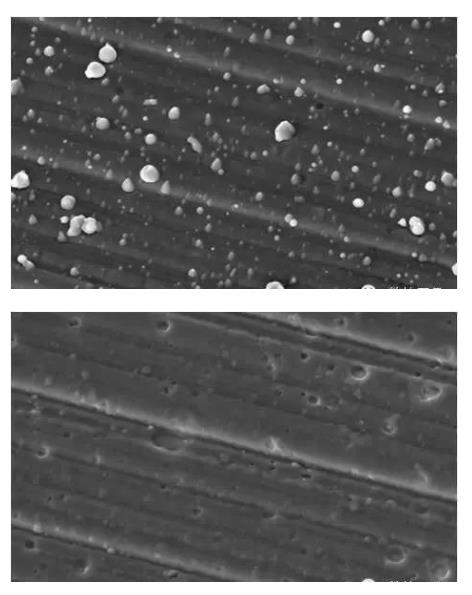

Polishing of the coating

The protruding droplets produced after removing the coating of the tool can improve the surface finish and increase the adsorption of lubricating oil.

The coated tool surface will produce some tiny protruding droplets, which improves the surface roughness, making the tool prone to generate greater frictional heat during the cutting process and reduce the cutting speed. After passivation and polishing, the droplets are removed, while leaving many small holes, which can absorb more cutting fluid during processing, greatly reduce the heat generated during cutting, and greatly increase the cutting speed.